nah... still 5 ply 1/2"... But with the 'broom pole' brace... aka 1/2" dowel front to back.

By the time a metal grill goes on the front, you aren't giving up enough spl to vibration to justify going from 40lbs to 72lbs worth of ply. Especially if you are going to hang a heavy 4015lf in it... the lighter ply is worth it's (lack of) weight. Weight was the primary reason I invoked the 'single sheet' demand on this design in the first place.

Keep in mind (everyone) the SS15 design is not a multi-kilowatt design, and is not meant to tackle the 'big boys.' It's a cheap, lightweight, easy to build, very efficient sub ideal for bar bands, dj's, installs, etc.. The fact that in multiples like flipc uses... it's downright scary... well that's a bonus.

Anyone who wants to armor up... may make the outside case with 3/4" without affecting any of the internals. It kinda goes against the spirit of 'single sheet' but oh well.....

By the time a metal grill goes on the front, you aren't giving up enough spl to vibration to justify going from 40lbs to 72lbs worth of ply. Especially if you are going to hang a heavy 4015lf in it... the lighter ply is worth it's (lack of) weight. Weight was the primary reason I invoked the 'single sheet' demand on this design in the first place.

Keep in mind (everyone) the SS15 design is not a multi-kilowatt design, and is not meant to tackle the 'big boys.' It's a cheap, lightweight, easy to build, very efficient sub ideal for bar bands, dj's, installs, etc.. The fact that in multiples like flipc uses... it's downright scary... well that's a bonus.

Anyone who wants to armor up... may make the outside case with 3/4" without affecting any of the internals. It kinda goes against the spirit of 'single sheet' but oh well.....

The 1/2" dowel is probably quite good in compression and thus "braces" against the panels "sucking in" when negative pressure exists inside the box.

What "braces" against positive pressure inside the box? Can the dowel work (provide stiff non extension) in tension relative to the forces and pressures acting?

What "braces" against positive pressure inside the box? Can the dowel work (provide stiff non extension) in tension relative to the forces and pressures acting?

Lol, there is only one to blame for the limitation set out for this challenge!

Of course everybody should build within his needs or preferences. But for those who are seriously considering an SS15 for high SPL’s, going 12mm (even for internals) is really not enough and braces are needed. However, braces can be reduced to half thickness of the panels without a problem (since forces on both sides of the braces are equal).

Indeed the “broom stick” method is very useful and its function can be improved by putting it in rings that are glued on the (inside) walls. This will enlarge the attachment surface and increases damping of the wall. I know it’s pretty old school, looks cheap, but it really works.

Of course everybody should build within his needs or preferences. But for those who are seriously considering an SS15 for high SPL’s, going 12mm (even for internals) is really not enough and braces are needed. However, braces can be reduced to half thickness of the panels without a problem (since forces on both sides of the braces are equal).

Indeed the “broom stick” method is very useful and its function can be improved by putting it in rings that are glued on the (inside) walls. This will enlarge the attachment surface and increases damping of the wall. I know it’s pretty old school, looks cheap, but it really works.

DJIM:

yea I hear ya.... However any serious design that's all about the max spl should probably never have a single sheet limitation in the first place... should be CNC cut, and use best in class drivers only... and yea, it's my fault that this whole topic of 'single sheet' has taken up over 1500 posts at this point.

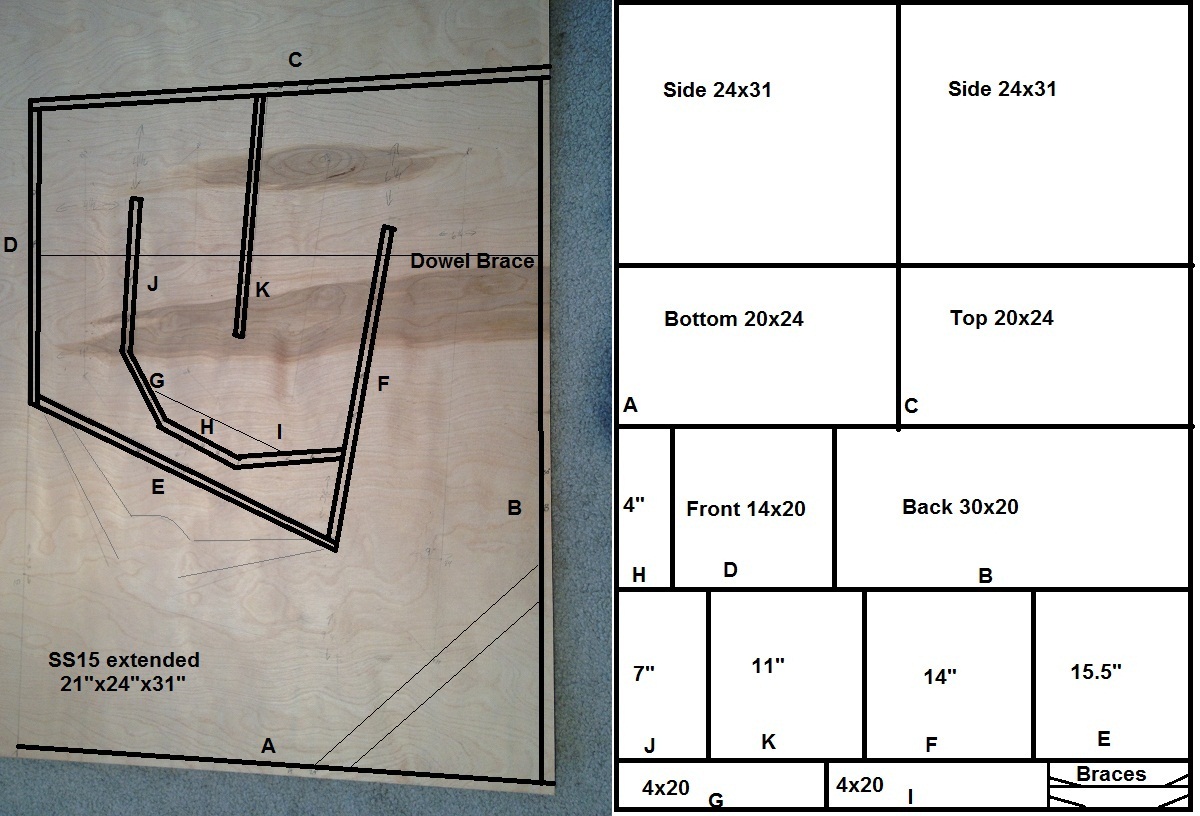

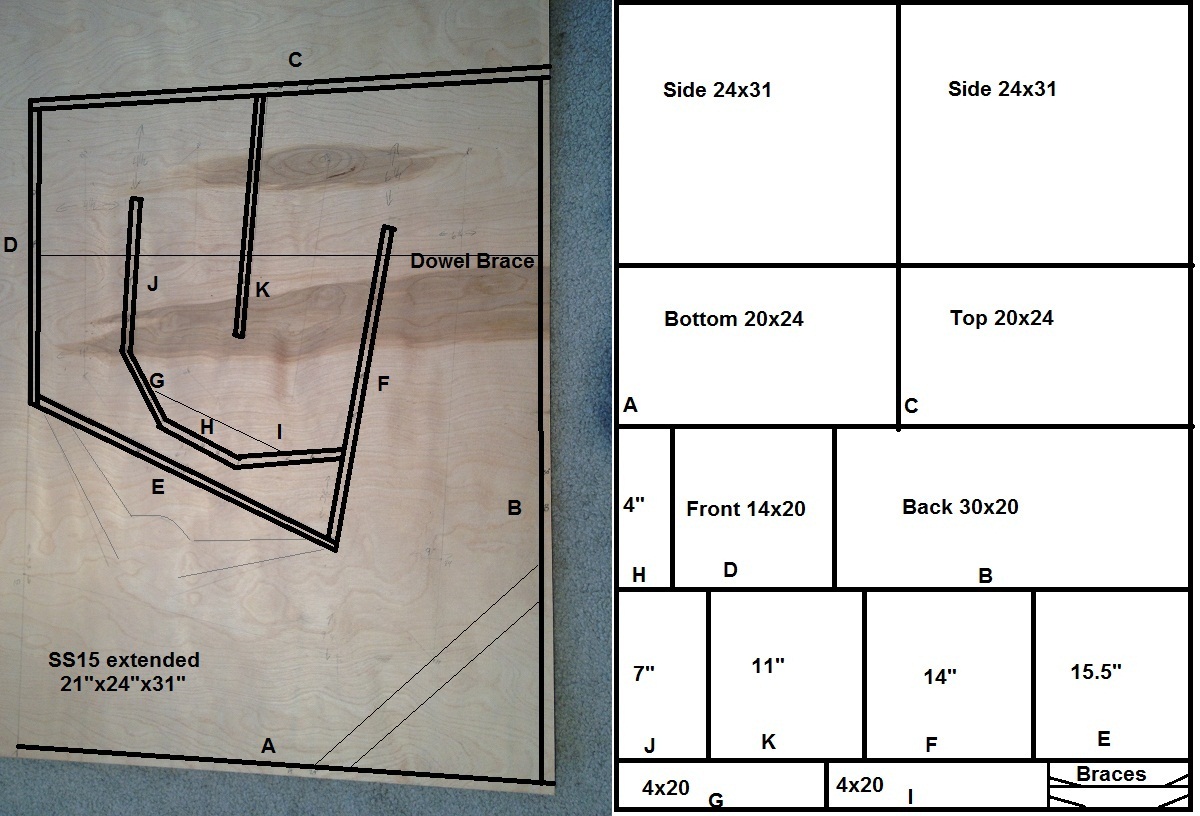

However... since it's your fault I was up past 1:00am rejiggering panel dimensions to stay within a single sheet, while increasing real 40hz output AND incorporating the S2-fix you've been working on...

what do you think of this attempt?

yea I hear ya.... However any serious design that's all about the max spl should probably never have a single sheet limitation in the first place... should be CNC cut, and use best in class drivers only... and yea, it's my fault that this whole topic of 'single sheet' has taken up over 1500 posts at this point.

However... since it's your fault I was up past 1:00am rejiggering panel dimensions to stay within a single sheet, while increasing real 40hz output AND incorporating the S2-fix you've been working on...

what do you think of this attempt?

JIM, I am more than happy to receive the blame for your new sleeping habits. To comfort your mind, there is absolutely no compassion from my side what so ever. If your wife complains about your new times, tell her, there is a man far away who feels sorry for her while he enjoys her husband's new frustration. If that isn’t satisfying enough for your wife, tell her she is more than lucky since her husbands efforts receive only encouraging and promising replies while not so long ago there was a time he would be tarred and feathered and be accused of certain voodoo practices.

........while not so long ago there was a time he would be tarred and feathered and be accused of certain voodoo practices.

http://www.diyaudio.com/forums/subwoofers/170771-single-sheet-th-challenge-35.html#post2457899

To be honest Jim, I think the man deserves more credits. He is also one of few who is prepared spending a lot of time and effort in testing and measuring in favour of the community. His Keystone folding style looks very promising too and I really like the idea of the extra volume between S4 and S5 to enhance the low end. If you design correctly you can position the extra volume on the frequency you wish.

Last edited:

To be honest Jim, I think the man deserves more credits. He is also one of few who is prepared spending a lot of time and effort in testing and measuring in favour of the community. His Keystone looks very promising and I really like the idea of the extra volume between S4 and S5 to enhance the low end.

We all learn... that's the great thing about this community. I just thought that was a great example of how things progress... I had no other reason for pointing to that post.

StadiumHorn would have never existed without Lilmike, David and Hornresp, a FLH fiasco, and a deadline.

SS15 would have never existed without screamersusa, flutes, clarinets, and a host of others input.

Many of my other unpublished designs wouldn't exist without the knowledge I've been fortunate to receive from members here and other places.

The reason I post some of my designs is my way of giving back. Many a small business has flourished with less than what is freely available on this forum.

Even after so long my colleagues favourite ‘wrap it up in his face’ moment is my 1/4wl mistake. Somehow it has become synonym for every mistake I make  .

.

I’m really curious about your findings of your new lay-out and hopefully you hit the jackpot in one time because I really can’t see how you can make panels from dust that is left.

.

. I’m really curious about your findings of your new lay-out and hopefully you hit the jackpot in one time because I really can’t see how you can make panels from dust that is left.

Hey jbell, I'm glad to see that the modification for cone volume compensation has made it from the other two bigger/lower PA TH threads over here to the SS15. Flat to 40 is something I'm also after, and if you say this gets it there, it sounds promising to me. Are you ready to post HR plots (or even inputs) comparing the two designs yet? Definitely looking forward to some measurements after you've made sawdust.

And Djim, what does the RCF L15P200AK cost in .nl/.be? Because over here in .de it's about 300€, which doesn't seem like such a good deal, considering you can get the original 3015LF for 250 or the Kappa Pro for 150.

And Djim, what does the RCF L15P200AK cost in .nl/.be? Because over here in .de it's about 300€, which doesn't seem like such a good deal, considering you can get the original 3015LF for 250 or the Kappa Pro for 150.

More ss15 developments...

Nice to see Mr Bell is still tweaking!

I made 4 of the original SS15's with my friends Phil and Marc and we have been playing with detachable "barn doors" to see what kind of extra performance gains are possible. Phil works with large touring rigs and has been keen to make a smallish tapped horn with collapsible extensions for a while and it really does work well.

We used 3 more sheets to make extensions for the 2x2 stacks, but for 4-8 db gain (curves for 1 box, 2 boxes and 2+extensions are attached), an extra 3/4 of a sheet per pox makes for a good sound to material ratio

They also unclip and pack flat...

It allows a pair of ss15s to hit a 45Hz corner, bumping up 40-45hz response by about 7-8db over a pair of subs with no extensions.

We came to the shape after a lot of experimentation with bits of ply and measurement mics, plus deciding on 600mm maximum extension from the front.

I can post sketches/plans if anyone else is keen, or just experiment yourself!

FYI, forum member Art Welter did something very similar with his keystone sub, and got equally impressive gains :

http://www.diyaudio.com/forums/subwoofers/184986-horn-extender-wave-guide-th.html

happy experimenting!

Richard

Nice to see Mr Bell is still tweaking!

I made 4 of the original SS15's with my friends Phil and Marc and we have been playing with detachable "barn doors" to see what kind of extra performance gains are possible. Phil works with large touring rigs and has been keen to make a smallish tapped horn with collapsible extensions for a while and it really does work well.

We used 3 more sheets to make extensions for the 2x2 stacks, but for 4-8 db gain (curves for 1 box, 2 boxes and 2+extensions are attached), an extra 3/4 of a sheet per pox makes for a good sound to material ratio

They also unclip and pack flat...

It allows a pair of ss15s to hit a 45Hz corner, bumping up 40-45hz response by about 7-8db over a pair of subs with no extensions.

We came to the shape after a lot of experimentation with bits of ply and measurement mics, plus deciding on 600mm maximum extension from the front.

I can post sketches/plans if anyone else is keen, or just experiment yourself!

FYI, forum member Art Welter did something very similar with his keystone sub, and got equally impressive gains :

http://www.diyaudio.com/forums/subwoofers/184986-horn-extender-wave-guide-th.html

happy experimenting!

Richard

Attachments

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge