Hi,

I was working on simulating a compact TH for the B&C 15sw115 (way too expensive for this thread, at over 500€ price tag), when I noticed that the 2.5m² of wood required was well within the spirit of the single sheet challenge (one 4x8 sheet is 3m²). So I looked around a bit for other drivers, and stumbled across the newish 15tbw100 from B&C, which looked promising.

As a starting disclaimer, this driver is not available for under 200 bucks, it costs 300€ here in Europe (so I'd imagine around 300$ in USA). However the original 3015LF is no longer under 200 bucks either, I believe last time I checked it was 240€ here. So with that in mind, I feel you might as well pay 60€ more for the beefy magnet, 4" VC and extra xmax and power handling. As such, I have decided to submit this design to this thread anyway. It may interest those with a slightly flexible budget who want something small.

The external dimensions of this sub are 64cm * 64cm * 53cm (25" * 25" * 21"). It is as such a full cubic foot (30l) smaller than the SS15, although it does take the same amount of wood to build.

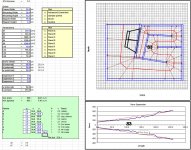

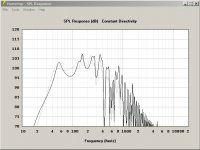

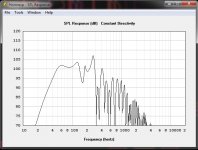

Despite this small size, my simulations show it beating the SS15 by about 4dB in max output, and playing a 1/3 of an octave lower. Here is my hornresp data (grey curve is SS15 at xmax) :

xmax as you can see is reached at at about 840W with no power compression, obviously more than that in the real world. As the driver is rated for 1500W/3000W, I think there should be enough thermal headroom to reach xmax. Compression ratio at about 3.33:1 is a bit high, but also manageable for a quality 15" I think.

If somebody is actually interested in building this, I do have a sketchup model, but currently still without dimensions marked. The folding style however is exactly identical to the OTHorn by Josh Ricci ( check out drawings and info here ), except using 12mm plywood, and scaled accordingly to my outer dimensions.

You'll need a fairly beefy amp for this, but Class D technology has made >1000WPC 8Ohm amps quite affordable these days.

I'd be interested in hearing what the experts think.

I was working on simulating a compact TH for the B&C 15sw115 (way too expensive for this thread, at over 500€ price tag), when I noticed that the 2.5m² of wood required was well within the spirit of the single sheet challenge (one 4x8 sheet is 3m²). So I looked around a bit for other drivers, and stumbled across the newish 15tbw100 from B&C, which looked promising.

As a starting disclaimer, this driver is not available for under 200 bucks, it costs 300€ here in Europe (so I'd imagine around 300$ in USA). However the original 3015LF is no longer under 200 bucks either, I believe last time I checked it was 240€ here. So with that in mind, I feel you might as well pay 60€ more for the beefy magnet, 4" VC and extra xmax and power handling. As such, I have decided to submit this design to this thread anyway. It may interest those with a slightly flexible budget who want something small.

The external dimensions of this sub are 64cm * 64cm * 53cm (25" * 25" * 21"). It is as such a full cubic foot (30l) smaller than the SS15, although it does take the same amount of wood to build.

Despite this small size, my simulations show it beating the SS15 by about 4dB in max output, and playing a 1/3 of an octave lower. Here is my hornresp data (grey curve is SS15 at xmax) :

xmax as you can see is reached at at about 840W with no power compression, obviously more than that in the real world. As the driver is rated for 1500W/3000W, I think there should be enough thermal headroom to reach xmax. Compression ratio at about 3.33:1 is a bit high, but also manageable for a quality 15" I think.

If somebody is actually interested in building this, I do have a sketchup model, but currently still without dimensions marked. The folding style however is exactly identical to the OTHorn by Josh Ricci ( check out drawings and info here ), except using 12mm plywood, and scaled accordingly to my outer dimensions.

You'll need a fairly beefy amp for this, but Class D technology has made >1000WPC 8Ohm amps quite affordable these days.

I'd be interested in hearing what the experts think.

I very much like this!. it seems halfway decent with the 15tbw100 as well!!!! Plus it could give me decent practice on building an othorn lol!

EDIT

sorry, thought yoru graph was with the 15sw115. I notice its with the tbw100. Why is your bl rating lower than spec?

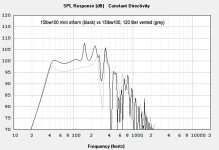

it does a good job of handily spanking a vented box of around 115 liters by about 4 db at xmax, although the vented box will do a bit better between 40 and 45 (in reference to itself)

EDIT

sorry, thought yoru graph was with the 15sw115. I notice its with the tbw100. Why is your bl rating lower than spec?

it does a good job of handily spanking a vented box of around 115 liters by about 4 db at xmax, although the vented box will do a bit better between 40 and 45 (in reference to itself)

Last edited:

sorry, thought yoru graph was with the 15sw115. I notice its with the tbw100. Why is your bl rating lower than spec?

I had HornResp calculate it using the spec values for Re,Vas,Sd,Fs and Qes.

Plus or minus a few percent won't really make a big difference in the results, drivers tend to vary that much among a series anyway.

Here's the 15SW115 sim if anybody is interested, it's 4" narrower (so another cu ft or so smaller) and goes 1dB louder. But like I said, not really in the spirit of this thread with a 500$ driver.

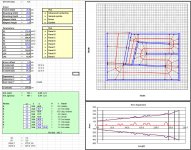

Here is an example of the spreadsheet, with S3 set as option 1 given above. The spreadsheet is not quite finished yet, but it's good enough to use to "tweak" the panel dimensions via computer before committing a design to wood.

...and here's an example of a folding that's closer to the SS15's scheme. Mapping out the expansion suggests S3 occurs at the base of the vertical panel as I indicated. (Ignore the numbers for S3, L23 and L34 to the right - the spreadsheet is still under development, so they are incorrect).

I should be finished with the spreadsheet in a few days, just in case anyone's interested.

Attachments

I'm still interested.

Pretty sure David McBean will be interested to!

No mean feat to develop a folding aid like you are showing.

It will eventually be finished, once I stop thinking of tweaks to add to it, LOL.

On the list of things to add:

1. Automatically moving the S3 point based on the choice of the second angle (which should be equal to the first or third angle, not independently set like it is now).

2. Visually identifying S2, S3 and S4 on the horn expansion graph.

3. Further optimization of the expansion guide (the red line in the horn expansion graph). To do this however I'll need to know the calculations to determine cross-sectional area at different points along the horn. At the moment I'm using an approximation.

4. Including braces in the cut list.

I had to abandon some of the optimization routines I was using. However, the horn expansion graph is a good visual guide to work out the best dimensions for the internal panels by trial and error, without cutting a single piece of wood

The B&C 15TBW100 seems to sim exceptionally well in a small tapped horn.

For instance substituting the Eminence 3015LF in jwmbro's sim in post 1981 results in a very poor frequency response with a big dip at 90Hz.

The optimal balance of LF extension, max SPL, and size is up to the user!

Sim attached showing the B&C 15TBW100 and the Eminence 3015LF in comparison in jwmbro's sim.

Regards Xoc1

For instance substituting the Eminence 3015LF in jwmbro's sim in post 1981 results in a very poor frequency response with a big dip at 90Hz.

The optimal balance of LF extension, max SPL, and size is up to the user!

Sim attached showing the B&C 15TBW100 and the Eminence 3015LF in comparison in jwmbro's sim.

Regards Xoc1

Attachments

I have not seen a better design for the 15tbw100 yet. granted it doesnt go super low.

FWIW, the 15tbw100 also sims fairly well in the 'cone volume correction' style SS15 (here's a photo of the one I built, I think there are plans somewhere in this thread too) that has been discussed here, which is in my humble opinion probably the optimal version of SS15 (I think Djim came up with it? not sure). The regular SS15 will most likely perform almost as well, I just didn't have the HornResp entry data handy.

Here's a sim of it at xmax, hyperlinked in order to not clog up the page with images, as you can see it's a bit peakier than my design, due to the relatively lower compression ratio, but it plays a bit louder (hoffman's iron law at work - the box is a cubic foot larger).

A matter of preference I think. The SS15 may be easier to saw, since I havent worked on a cutsheet for the other design yet.

EDIT: And of course both of them only play down to 40Hz, this is not the sub for you if you want lower content than that, I imagine the 15tbw100 would do well in the 15" Keystone sub, or several of the other designs aimed at lower response that can be found in this forum. Try em yourself, I'd look at the C/E/X horn, the Keystone, maybe the PAL-12 and probably a few more I can't think of right now.

Last edited:

I'm still interested.

Pretty sure David McBean will be interested to!

No mean feat to develop a folding aid like you are showing.

Here's what the latest version looks like. I think I've worked out all the bugs (including a major one that basically indicates that my POC3 design is a lot longer than I planned, groan).

If you'd like to give it a spin, let me know. I'll likely add it to the "spreadsheet" thread in a week or two anyway, once I've completed POC3 and had a chance to compare predictions to actual results.

Attachments

Brian, is that design still a single sheet? If so, it looks really nice!

I built two SS15s a while ago, but they are not completly finished yet, so havent really tested them.

I used Xoc1´s extended version as a baseline, and then I tweaked it to better suit the new version of the Kappalite 3015LF´s that I have, I also tweaked it so all the panels actually fitted on a 12x1220x2440mm sheet, with sawblade margins

I simulated a couple of different versions with more cone correction, but they actually gave a slightly worse result than what I ended up building.

If any one wants more drawings or such for this version, ask me and I can send autocad drawings with all measurements.

But beware, I went a bit of the single sheet thinking here, all the 12mm panels fit one sheet, with not much more than dust left, but all the bracing and reinforcements for the handles are made from 9mm, I used about a half sheet of 9mm for two cabs. So, they arent really SS15´s

All the braces are double, I used them as moulds during the build, they were all routered with cnc-cut aluminium molds, fancy, I know

Some pictures here:

https://drive.google.com/folderview?id=0B8yhy6Gs5tGqbGlORFlxd3BkRHc&usp=sharing

Would be interesting to simulate "my" version of the SS15 with the 15tbw100 or some other nice 15", I´ll do that some day

But for now I think I´ll be using the 3015s that I have, I have 2 more sitting in T48s also that probably will get SS15 cabs if the first two works out good.

I built two SS15s a while ago, but they are not completly finished yet, so havent really tested them.

I used Xoc1´s extended version as a baseline, and then I tweaked it to better suit the new version of the Kappalite 3015LF´s that I have, I also tweaked it so all the panels actually fitted on a 12x1220x2440mm sheet, with sawblade margins

I simulated a couple of different versions with more cone correction, but they actually gave a slightly worse result than what I ended up building.

If any one wants more drawings or such for this version, ask me and I can send autocad drawings with all measurements.

But beware, I went a bit of the single sheet thinking here, all the 12mm panels fit one sheet, with not much more than dust left, but all the bracing and reinforcements for the handles are made from 9mm, I used about a half sheet of 9mm for two cabs. So, they arent really SS15´s

All the braces are double, I used them as moulds during the build, they were all routered with cnc-cut aluminium molds, fancy, I know

Some pictures here:

https://drive.google.com/folderview?id=0B8yhy6Gs5tGqbGlORFlxd3BkRHc&usp=sharing

Would be interesting to simulate "my" version of the SS15 with the 15tbw100 or some other nice 15", I´ll do that some day

But for now I think I´ll be using the 3015s that I have, I have 2 more sitting in T48s also that probably will get SS15 cabs if the first two works out good.

Attachments

Last edited:

Here's the 15SW115 sim if anybody is interested, it's 4" narrower (so another cu ft or so smaller) and goes 1dB louder. But like I said, not really in the spirit of this thread with a 500$ driver.

A small design like this needs quite a powerful driver (strong magnet and high power handling), which are typically fairly expensive.

However Dayton is set to release their new line of PA drivers, "inspired by popular Italian made pro audio drivers" and this PA385S-8 15" driver specifies a BL of 31Tm and a 1kW power handling at under 200$.

Much of this design hinges on whether this driver will live up to its specs when released (was supposed to be available from today, but seems to have been pushed back). If it does however live up to these, I think I have a potential SS15 alternative design (if you're willing to accept the tradeoffs it makes) that is definitely worth submitting here.

It measures 64 x 64 x 43 cm (25 x 25 x 17 inches) and at 150l internal volume (about 6 cu ft external volume) it is quite a bit smaller than the SS15, and as a result of this unsurprisingly is about 2dB less sensitive. The flipside though is that it will play a few Hz deeper (flat down to an F3 of 40Hz even from a single cabinet) and due to much higher power handling should play 2dB louder at full blast.

The Dayton driver is quite heavy, so even though the box is quite a bit smaller, it will definitely be heavier than jbell's SS15. But if space is at a premium, and load weight & amplifier power are not, I think this is a pretty good bet. It'll require an amp that will do about 100V, but these can be had fairly cheaply these days. I figure you could run 4 of these from a single Behringer NU6000DSP, which is about 137dB flat down to 40Hz according to HornResp. Not bad from about 1600$ worth of parts total (the design is definitely easily single sheet, I did a quick and dirty cut sheet to make sure).

Keep an eye on this thread for reports on real world performance of these drivers. If they can take the 2kW peaks they are rated for, and the cone will handle a 4:1 compression ratio while moving 1cm each way, it looks like a Goliath-killer to me.

Not bad from about 1600$ worth of parts total (the design is definitely easily single sheet, I did a quick and dirty cut sheet to make sure).

You're going to need to put a lot of bracing into that build, especially the top panel, which is going to increase amount of wood you'll need to use. One of the beauties of the "SS15" fold to me is that one of the panels actually acts as a cross-brace for the top of the enclosure, so theoretically you could get away with less bracing at that point.

You're going to need to put a lot of bracing into that build, especially the top panel, which is going to increase amount of wood you'll need to use. One of the beauties of the "SS15" fold to me is that one of the panels actually acts as a cross-brace for the top of the enclosure, so theoretically you could get away with less bracing at that point.

Maybe so, but my top panel is 25x16" - the back panel of the SS15 is 29x21" and that one doesn't have any inbuilt bracing. I think if you can get that braced up enough, the massive 8 food long strip of material left in the sheet should be enough to get the top panel vibration free.

Though in a sense I agree with you - if that driver can truely do 127dB power compression free (remains to be seen), you're going to have a lot of pressure in the enclosure, might as well spring the extra 10kg or so of weight and make it out of 18mm ply. Though you'll be at over 40kg total weight then. For me the SS15 is more bulky than it is heavy, at least for a one-man carry job, I think I'd prefer to have it smaller than to have it lighter (bear in mind mine is using an iron magnet version, not the super light neo 3015lf either).

Even so, the angled bottom edge will nicely fit two fixed casters, making it super easy to roll.

Maybe so, but my top panel is 25x16" - the back panel of the SS15 is 29x21" and that one doesn't have any inbuilt bracing.

Based on my results from a similar build, the back panel isn't as prone to vibration as the top and bottom panels, which I think is likely due to their various positions along the horn's path. The impact of any panel vibration at the back is a lot less as well, as any significant vibration of the top and bottom panels can add significant measurable distortion if that vibration brings them into contact with another surface, e.g. the floor or a "top" mounted on top of the subwoofer box. I once measured a significant increase in distortion from my POC #1 TH build that turned out to be caused by a small stone caught between the bottom panel and the ground, LOL. The use of two "rails" near the outer edges of the bottom panel eliminated this problem from happening again.

I think if you can get that braced up enough, the massive 8 food long strip of material left in the sheet should be enough to get the top panel vibration free.

Though in a sense I agree with you - if that driver can truely do 127dB power compression free (remains to be seen), you're going to have a lot of pressure in the enclosure, might as well spring the extra 10kg or so of weight and make it out of 18mm ply. Though you'll be at over 40kg total weight then. For me the SS15 is more bulky than it is heavy, at least for a one-man carry job, I think I'd prefer to have it smaller than to have it lighter (bear in mind mine is using an iron magnet version, not the super light neo 3015lf either).

Even so, the angled bottom edge will nicely fit two fixed casters, making it super easy to roll.

One possibility is using a mix of panel thicknesses, e.g. thinner ply for the internal panels and thicker ones where the horn would be subject to the most vibration. It may take a couple of iterations to get the perfect mix though, and of course you'll no longer be using just one sheet of ply (maybe two half-sheets can count as one sheet in the challenge?

One possibility is using a mix of panel thicknesses, e.g. thinner ply for the internal panels and thicker ones where the horn would be subject to the most vibration. It may take a couple of iterations to get the perfect mix though, and of course you'll no longer be using just one sheet of ply (maybe two half-sheets can count as one sheet in the challenge?)

As is used in the Ricci's othorn (which this fold is based off of)

Seriously though, its not that difficult to brace effectivly.

I'd consider adding an extra layer of 1/2 ply on the rear 45 angle piece (for caster mounting). a couple months of lugginb will form cracks there.

what are the effects of shrinking S1 (ala Othorn) for extra bracing of the driving mounting panel?

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge