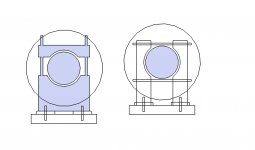

I sketched two designs for isolating a woofer from it's dipole baffle. The driver would be clamped by its magnet using a sorbothane insulator. The clamp would be isolated from its base using rubber motor mounts. The base would be made of a 12" x 12" flagstone paver, selected for its mass as well as aesthetics. If necessary, the paver would sit on sorbothane feet for further isolation.

The woofer would be isolated from the baffle which would contain a small full range driver and both would be freestanding. The front of the woofer's rubber mounting ring would be placed in close proximity to the back of the baffle, but not touching.

My goal is to severely decrease the vibration coming from a woofer that has high xmax, high qts and high moving mass (close to 2 grams).

I have experience in eliminatng vibration and noise transmission from small motors and pumps by building custom isolation mounts. Just curious what obstacles I might run into in attempting to do the same for drivers.

The woofer would be isolated from the baffle which would contain a small full range driver and both would be freestanding. The front of the woofer's rubber mounting ring would be placed in close proximity to the back of the baffle, but not touching.

My goal is to severely decrease the vibration coming from a woofer that has high xmax, high qts and high moving mass (close to 2 grams).

I have experience in eliminatng vibration and noise transmission from small motors and pumps by building custom isolation mounts. Just curious what obstacles I might run into in attempting to do the same for drivers.

Attachments

My goal is to severely decrease the vibration coming from a woofer that has high xmax, high qts and high moving mass (close to 2 grams).

The above post should read (close to 150 grams). The MMS stated initially was incorrect. Sorry about that.

...

I have experience in eliminatng vibration and noise transmission from small motors and pumps by building custom isolation mounts. Just curious what obstacles I might run into in attempting to do the same for drivers.

You will most probably improve your sound, because the baffle will be

excited less from the driver from lower midrange on upwards.

The resonant frequency of the driver/mounting should be

at the bottom end of the drivers frequency range or below.

Sufficient damping is required, which should often be OK with

rubber bumbers not too hard.

BTW. What happened to your " OB rear wave cancellation" technique ?

Any new solutions ?

Kind Regards

Hi Oliver,

Good to hear from you. With regard to the rear wave cancellation, I ended up using some acoustistuff in a nylon net. It hangs off the rear baffle and loosely covers the back of the full range driver. I've listened for hours with and without the rear "muffler" and decided I like it better with. Thanks for your help with that one. The only porous metal I had access to was some steel wool , which didnt have a pleasing sound at all.

, which didnt have a pleasing sound at all.

With regard to the magnet mounting, my plan was to only suspend the driver from it's magnet. Alternatively I could fasten one or more of the drivers mounting holes to the mass loaded bass as well. Can you speculate on whetehr that might add or detract from vibration damping?

Good to hear from you. With regard to the rear wave cancellation, I ended up using some acoustistuff in a nylon net. It hangs off the rear baffle and loosely covers the back of the full range driver. I've listened for hours with and without the rear "muffler" and decided I like it better with. Thanks for your help with that one. The only porous metal I had access to was some steel wool

With regard to the magnet mounting, my plan was to only suspend the driver from it's magnet. Alternatively I could fasten one or more of the drivers mounting holes to the mass loaded bass as well. Can you speculate on whetehr that might add or detract from vibration damping?

From my gut feeling i would prefer magnet mounting, since

the motor is where the forces originate.

That makes sense to me as well. In your Dipole 08 design, how does the stone slab interact with the driver's magnet cover. I imagine you are using something like a rubber gasket, or if your speakers dont attach to the baffle directly, was the slab cemented to the magnet cover? That's a very interesting design btw.

The magnets are glued to the stone using

a very good 2 component epoxy mixed from

experience to stay a bit flexbile for reasons

of durability.

(See below)

Stone "spine" and baffle are both sandwiches

with a constraint layer of dampening sealant

inbetween.

(Needed weeks to harden ...)

Spine: Marble, Sealant, Marble

Baffle: HPL, Sealant, HPL

One of the baffle layers is also attached to the

baskets using gaskets and soft grummets.

Kind Regards

a very good 2 component epoxy mixed from

experience to stay a bit flexbile for reasons

of durability.

(See below)

Stone "spine" and baffle are both sandwiches

with a constraint layer of dampening sealant

inbetween.

(Needed weeks to harden ...)

Spine: Marble, Sealant, Marble

Baffle: HPL, Sealant, HPL

One of the baffle layers is also attached to the

baskets using gaskets and soft grummets.

Kind Regards

Attachments

Last edited:

We are definately on the same page. Makes perfect sense. Now that you have lived with your design for some time, is there any part of the construction technique you would have done differently? Did you think about clamping the drivers under force instead of your layered sealant approach? If the "clamp" was used to exert force on the drivers frame in more than one direction, you may effectively reduce basket resonances without having to add mass to the driver, etc.

I am very pleased with the 10" woofers I am using, with an xmax of 13mm and a QTS of .62. They really lend themselves well to dipoles. Since they are designed as automotive subwoofers, and have a steel frame, they are not the quietest choice for dipoles... but not horrible either. If I can dampen just a little bit of their resonant energy, I will be happy.

I am very pleased with the 10" woofers I am using, with an xmax of 13mm and a QTS of .62. They really lend themselves well to dipoles. Since they are designed as automotive subwoofers, and have a steel frame, they are not the quietest choice for dipoles... but not horrible either. If I can dampen just a little bit of their resonant energy, I will be happy.

I thought about clamping baskets to the spine

in the beginning, but decided to glue because

it is very slim, there are no further objects in

the rear way and no objects visible.

Due to maintenance, clamping might be

more practical indeed. But i think i could even

manage to change a driver if it was broken ...

(No please ...)

I would do some improvements, but that's

more due to technical detail

(sizing, crossover network).

The overall construction is OK and also

survived some transports.

I do not know if i made the baffle

from HPL the next time.

But i would not want the speaker to

look the same, if i was to build another

offspring of that, that would be boring.

Maybe i would go into the aerospace

design direction using concrete for the

spine ...

Many people like the real object,

although it is rather technical looking

and not very "integral" from design.

Most women like it although i thought

it would be rather a men's object.

Kind Regards

in the beginning, but decided to glue because

it is very slim, there are no further objects in

the rear way and no objects visible.

Due to maintenance, clamping might be

more practical indeed. But i think i could even

manage to change a driver if it was broken ...

(No please ...)

I would do some improvements, but that's

more due to technical detail

(sizing, crossover network).

The overall construction is OK and also

survived some transports.

I do not know if i made the baffle

from HPL the next time.

But i would not want the speaker to

look the same, if i was to build another

offspring of that, that would be boring.

Maybe i would go into the aerospace

design direction using concrete for the

spine ...

Many people like the real object,

although it is rather technical looking

and not very "integral" from design.

Most women like it although i thought

it would be rather a men's object.

Kind Regards

Most women like it although i thought

it would be rather a men's object. Kind Regards

LOL, then perhaps you have accomplsihed something in speaker design where most have failed.

Thanks again for your help. You are a wealth of information in a fairly obscure design concept!

Durometer and thickness? I'm curious what resonance frequency you chose as a cutoff.The driver would be clamped by its magnet using a sorbothane insulator.

Durometer and thickness? I'm curious what resonance frequency you chose as a cutoff.

The drivers have an Fs of 33Hz and are crossed using F-mods at 200Hz, 12dB/octave. They have a thick, coated paper cone designed for the elements, which results in a fairly high MMS of about 155 grams. Using a length of heater hose placed to my ear, I placed the other end at various points and am pretty confident the resonances are coming from the baffle as opposed to the driver itself.

The baffle is made of three layers, the outer being 1.2" hardwood, the center 1/4" compressed foamboard, and the inner is another layer of 1.2" hardwood. While the wood is fairly dense and fine grained, the overall baffle dimensions are small so the resulting weight isn't all that much, maybe only 20-25 lbs.

My thought was to physically decouple the driver from the baffle, with the exception of a rubber insulation channel used to reduce leakage at the "seal". The driver would be clamped at its greatest mass, it's magnet, and attached with rubber mounts to a hefty base, independent from the baffle.

Ed

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Magnet mounting dipole drivers w/high moving mass