you can look up the curves (http://en.wikipedia.org/wiki/A-weighting) but the "overly simplistic" way to convert from c-weighted to flat, is to add 2db @40, and add 1db @50 over what the rat shack says.

Is coupling a pair of cabinets an option? It opens up some more possibilities for you. (as well as gives you a nice base for a stack of tops, when you are using 4)

Is coupling a pair of cabinets an option? It opens up some more possibilities for you. (as well as gives you a nice base for a stack of tops, when you are using 4)

screamersusa said:Boy I feel dumb...

How do I convert from the rat shack to flat?

It's the digital one.

Screamerusa,

From a quick google check it appears that the “C” weighting response is about -6 dB at 20 hz from 1K. The Wikipedea article shown the actual formulas.

However, a simple conversion is unlikely to be very accurate.

Your particular mic may not be conforming near that well to “C”, for the price you pay for a R.S. meter they are pretty darn close around 1K, but only ballpark in the low or high range of hearing. If you add +/- 3 dB to the C spec you can be pretty far off flat even within the R.S. mic spec.

I have found that the mic provided with my Sencore Audio Toolbox was 10 dB lower in response at 20 HZ than 200 HZ on “flat” response. Made me think I had been making some lousy cabinets when it was a mic problem. Turns out the mic that came with a cheap DOD RTA was far closer to flat than the Audio Toolbox.

I am using a B & K 4004 with SMAART for critical testing, but have made a correction chart for my Audio Toolbox with the funky mic that I use for dirty work.

As they say, close only counts in horseshoes and hand grenades. You don’t need to spend $1500 on a test mic to get in the ballpark, but hoping a mic element that costs less than $1 to be lab grade is only a hope.

If you want to continue using your RS meter for testing, the only way to be sure of it’s accuracy would be to do a deviation chart against a known accurate mic (not that easy to find) in the same position and angle and distance to any reflective objects and the sound source.

Gotcha on the measurement.

But in a live sound situation there is 99% no chance of corner loading.

I know there is a company who actually sells

and promotes this exact setup for their horns. I just cant recall whom right now. Definite way to get a bit extra extension.

I believe Function One

uses a bigger example on thier Infrabass boxes.

But in a live sound situation there is 99% no chance of corner loading.

I know there is a company who actually sells

and promotes this exact setup for their horns. I just cant recall whom right now. Definite way to get a bit extra extension.

I believe Function One

uses a bigger example on thier Infrabass boxes.

I've compared the rat shack to my behringer ecm setup with the laptop. It's close enough for govt work. Since I'm trying to beat the direct radiator, I am using a 4015 in a box that's close to the best one emminence suggests as a reality reference.

This chart shows the difference between the tapered cabinet and the super simple one and the direct radiator.

Green is the simplified cabinet with tapers.

The pencil line is the direct radiator.

The TH (tapered) creams the direct radiator above 50.

But the LF falloff is about the same. If I try to make the horn longer or simpler I lose top end as shown by the yellow and purple lines which are the super simple version, No tapered braces.

Id be very happy with the tapered one if I could just get 42-45hz up a few db without making a bigger box. I could add another short horn length in the wasted area, but, my experience has been that the 180 bends hurt the middle response pretty bad.

Maybe some kind of resonator would help.

This chart shows the difference between the tapered cabinet and the super simple one and the direct radiator.

Green is the simplified cabinet with tapers.

The pencil line is the direct radiator.

The TH (tapered) creams the direct radiator above 50.

But the LF falloff is about the same. If I try to make the horn longer or simpler I lose top end as shown by the yellow and purple lines which are the super simple version, No tapered braces.

An externally hosted image should be here but it was not working when we last tested it.

Id be very happy with the tapered one if I could just get 42-45hz up a few db without making a bigger box. I could add another short horn length in the wasted area, but, my experience has been that the 180 bends hurt the middle response pretty bad.

Maybe some kind of resonator would help.

How quickly can you build a 2nd CTH? so you can 90 degree plate them together, and measure? The extra bit of length/mouth area should help your 40hz, as well as eek out another db or two across the board.

Worth a shot -- and it doesn't involve sleepless nights or loss of brain cells to try.... Sounds like the CTH is just about there in terms of doing what you need.

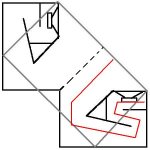

Here's my thinking... I measured 102.5 @40hz 1M 2.83v with a single cabinet. I measured 114@40hz 10M 20v. So, I gained either directivity, or mutual coupling, to account for my additional gains with 4 cabinets. Usually doubling direct radiator cabinets, never quite gets to the 6db expected... In my case, I was getting 2.5 db above and beyond 6db per doubling of cabinets. I'm thinking that when you build the 2nd - 6th.. you'll be happier than just the tests of a single cabinet show. (The attached pic is how I had the cabinets set, when I measured 114)

I never did measure the plate trick on my TH, so I can't give you any numbers, but I believe it'll help. I know when I was testing my T36 without the covers on, that a plate on top (so I was getting horn loading from the open chambers) helped ALOT. Actually it was that test, that led me to try TH....

Worth a shot -- and it doesn't involve sleepless nights or loss of brain cells to try.... Sounds like the CTH is just about there in terms of doing what you need.

Here's my thinking... I measured 102.5 @40hz 1M 2.83v with a single cabinet. I measured 114@40hz 10M 20v. So, I gained either directivity, or mutual coupling, to account for my additional gains with 4 cabinets. Usually doubling direct radiator cabinets, never quite gets to the 6db expected... In my case, I was getting 2.5 db above and beyond 6db per doubling of cabinets. I'm thinking that when you build the 2nd - 6th.. you'll be happier than just the tests of a single cabinet show. (The attached pic is how I had the cabinets set, when I measured 114)

I never did measure the plate trick on my TH, so I can't give you any numbers, but I believe it'll help. I know when I was testing my T36 without the covers on, that a plate on top (so I was getting horn loading from the open chambers) helped ALOT. Actually it was that test, that led me to try TH....

Attachments

DJM.. That's a sweet little housewrecker scheme.

I've been re reading many of your posts as well.

Is there a schematic view or horn structure view in akback?

Can you model multiple horns using the same driver?

(I.E.) One driver, two horn paths.

Jim: I tried modeling multiple boxes and it does seem that the bottom starts to get rather serious at 3 boxes. I guess I'm closer than I thought. I redesigned a slightly longer version with the tapers I'll try over the next few days. The tapers make a huge difference and yield a pleasing sounding clear cabinet.

Got a outdoor gig Feb2 so I need to git-r-done.

I need to work on learning akback to add compression etc in a better fashion and work with more segments.

I've been re reading many of your posts as well.

Is there a schematic view or horn structure view in akback?

Can you model multiple horns using the same driver?

(I.E.) One driver, two horn paths.

Jim: I tried modeling multiple boxes and it does seem that the bottom starts to get rather serious at 3 boxes. I guess I'm closer than I thought. I redesigned a slightly longer version with the tapers I'll try over the next few days. The tapers make a huge difference and yield a pleasing sounding clear cabinet.

Got a outdoor gig Feb2 so I need to git-r-done.

I need to work on learning akback to add compression etc in a better fashion and work with more segments.

New Version prototype started today. Templates done.

It got a little bigger to 40x25.5x31.5. The horn path got 14 cm longer and the driver is repositioned. I revised the ramp scheme after looking at some duct dynamics info on the web. The tapers have been tweaked and are going back in for the first stages. Should have it tested in about two days. Third time's a charm I hope.

It got a little bigger to 40x25.5x31.5. The horn path got 14 cm longer and the driver is repositioned. I revised the ramp scheme after looking at some duct dynamics info on the web. The tapers have been tweaked and are going back in for the first stages. Should have it tested in about two days. Third time's a charm I hope.

MarjanM said:You have to be aware that TH115 has a horn length of around 270cm (9ft). You must have a horn of approximate length to achieve strong response down to 40Hz.

Looking at your scheme i can see that you are missing one more fold in the first part of the horn.

Hmm. That's good to know. Thank you.

I'm trying to balance the upper end response as well to meet up with BFM OT12's (modified). I've tried adding another fold but the response above 95hz is not any better than a direct radiator.

The slightly shorter tapered box had very nice usable upper end vs the longer extra fold boxes...all 20 or so of them I tried. Getting a box to play to 40 from 80hz and below isn't that hard, but you need 15" 3way tops to go with them especially in arrays..

I cannot build 10 replacement tops for a while so these will have to serve for now. This would give me more time to learn Akbak and other knowledge to design a better one. Lots of people have Omnitops so the final box won't be a waste.

I'm going for a compromise to 42-45hz with a 260cm path with smooth tapers and no 180 degree bends, 103db average at 1w1m equal to a double 18 bin. That box is bigger than it looks. Without a sense of Master Tom's method of maintaining upper end response, I know I'll be very lucky if I can match the UCS1.

The power curve on the TH is interesting, so I've started looking at different wattage vs spl ratings in my DR vs TH physical tests.

After this TH project is done, I start the new tops as funds come in. Somewhere along the line I have an adjustable prototyping scheme for the next Live use TH project. It allows one to adjust the sidewall taper sections from outside the prototype box. It will have a plexiglass faceplate so one can verify alignment as well as 1.5" boat plug holes to access different parts of the horn to test the path. This way real time adjustments can be made to a much smaller standard sized box and path length to optimize for different drivers. Also will allow for some interesting experimentation on compression along horn lengths.

MarjanM said:You have to be aware that TH115 has a horn length of around 270cm (9ft).

Speculation or fact?

TIA,

GM

screamersusa said:.........I have an adjustable prototyping scheme for the next Live use TH project.

I'm curious, are you licensed to use TD's patent pending TH concept for personal gain?

GM

Perhaps it's time to come up with a new name for DIY projects using the technology in this (expired) patent:

http://www.google.com/patents?id=_JRJAAAAEBAJ&pg=PA1&dq=2604182&source=gbs_selected_pages&cad=0_1

http://www.google.com/patents?id=_JRJAAAAEBAJ&pg=PA1&dq=2604182&source=gbs_selected_pages&cad=0_1

GM said:

I'm curious, are you licensed to use TD's patent pending TH concept for personal gain?

GM

I'm not planning on selling them. But since you mention it...

If one were to enforce patents in the Microsoft way, then 99 percent of the speakers in the world are illegal. Every chord progression you play on any instrument would be copywrited.

And every invention would end where it began simply because

it's variations in original ideas and imitation that bring progress.

Considering that my eventual intention is to utilize TD's concept to actually buy his product, and I have no other way to do so otherwise, building these would wind up benefiting him anyway.

On top of that I am constantly asked to recommend gear to people WHO HAVE MONEY to spend, because they respect my DIY system against thier own Store bought systems or more expensive sound companies. As soon as they realize that I have built them, they start asking questions.

The first one is always how much to buy mine, the answer is always "I don't build them for sale but such and such from manufacturer X would be just as good or better" or "You can buy the plans from...". I could have sold at least 50 of my old tops by now, and they were easy to build, but instead I told them, to buy the original JBL or EAW design they were based on. Interestingly enough Meyer is now making the same box, with thier own touches of course.

If TD disagrees, he may most certainly email me through my site or prosound web discreetly as to how he would like this handled.

With all due respect, either a Russian or Asian company will reverse engineer one soon enough causing TD a real headache.

Do look on Alibabba.com, You'll find original Crown's, Jbl's, Mackies, and a host of others with different names on them coming out of the exact same factories the originals are made in as well as cheap knock offs. I got to compare a cheap ASHTONE cabinet to the apparently cloned Cerwin Vega only to discover the same exact box with the same exact qc stickers.

Same box, same factory, different badge, $200.00 price difference.

Sorry for the rant folks.

Let me say I’m not a qualified legal person so you should take my words with a gain of salt. However, I have spoken to a couple patent attorneys and both believed that there was too much prior art to justify granting TD’s current patent application. Once again, take these words with a grain of salt.

screamersusa said:After this TH project is done, I start the new tops as funds come in.

huh? did I miss something? anything to share? I've spent hours trying to find the best 12x24x24 top cabinet design of late for a single 10.

Another interesting thought that was presented to me, was a concept for a TH midbass top, to reach down to subs...

Attachments

JBELL

The otops are not cutting it. They are probably the loudest and cleanest otops out there but the design has some limitations.

You had the right Idea by extending the dual 10 design and the piezos work for your application. In my case the piezos were a dismal failure and I had to go with compresion horns.

They sound great but the ports are a big problem and the horn cuts off too fast so you are limited in sub choices.

The new design is an 18 inch deep two stage horn, with a round throat entry and a quasi phase plug behind the centrally mounted PV22xt 5x14 horns. 24x15x22in box.

Two CTH1524s variations got built today. Both at 269cm but different internal arrangements. The first one failed, it went lower but lost high end and level. I don't have high hopes for the other either. I'll try it tomorrow and possibly put the original one back together adding 10 cm to it.

I'm looking at trying to model some double 15 4015 bins in akbak as a backup plan as I am way past my sub building time and eating into repair time for the next few shows. I really don't want to have to rent Meyer 650's and work for free.

The otops are not cutting it. They are probably the loudest and cleanest otops out there but the design has some limitations.

You had the right Idea by extending the dual 10 design and the piezos work for your application. In my case the piezos were a dismal failure and I had to go with compresion horns.

They sound great but the ports are a big problem and the horn cuts off too fast so you are limited in sub choices.

The new design is an 18 inch deep two stage horn, with a round throat entry and a quasi phase plug behind the centrally mounted PV22xt 5x14 horns. 24x15x22in box.

Two CTH1524s variations got built today. Both at 269cm but different internal arrangements. The first one failed, it went lower but lost high end and level. I don't have high hopes for the other either. I'll try it tomorrow and possibly put the original one back together adding 10 cm to it.

I'm looking at trying to model some double 15 4015 bins in akbak as a backup plan as I am way past my sub building time and eating into repair time for the next few shows. I really don't want to have to rent Meyer 650's and work for free.

- Home

- Loudspeakers

- Subwoofers

- Live sound specific Tapped Horn thread...