Well, I thought I would see somthing more convincingly show the marketing gimmic. Having seen pictures of the early concept exploration units, the idea seemed quite sound to me although I had not tried the concept. The test device actually showed a closed volume at the end of the sealed transmission line, not sure whether it was implemented in the final design.

At least get the dimensions to tuned to the driver in the sim, please.

At least get the dimensions to tuned to the driver in the sim, please.

Last edited:

Posts #3955 and #3957

Hi David,

As I'm not a Nautilus speaker owner (I wish, if for no other reason than that a pair of those should come w/ eight power amplifers, and assorted other electronics, and you can never have enough power amplifiers ) I cannot but largely agree w/ your assessment, even if B&W's cute little video claims: "...it works pretty well..."; obviously, a refined technical statement from their Technologies section.

) I cannot but largely agree w/ your assessment, even if B&W's cute little video claims: "...it works pretty well..."; obviously, a refined technical statement from their Technologies section.

I played around w/ similar designs in the early 1970s, and never found quite what I thought I was looking for. One that sounded quite well was an "omnidirectional" sealed column that I packed from the bottom up, first w/ a layer of pressed fiberglass ceiling tile, then fiberglass insulation, and finally some very light pillow stuffing around the driver area.

In those days I had no way of decently measuring the results, and there was no "Hornresp". I definitely don't want to go back to cut-and-try loudspeaker building, it is much more fun (and environmentally friendly) to simulate.

Anyway, the point I'm trying to make is that this highly resonant column sounded better when stuffed as described above, than when just lightly packed w/ an even density of e.g.: fiberglass.

I was wondering if you had any plans to further refine you software, to assign different airflow resistivities to different horn sections? It would indeed be a great feature.

Thank you very much for you efforts, and have a wonderful holiday season.

Regards,

Hi David,

As I'm not a Nautilus speaker owner (I wish, if for no other reason than that a pair of those should come w/ eight power amplifers, and assorted other electronics, and you can never have enough power amplifiers

I played around w/ similar designs in the early 1970s, and never found quite what I thought I was looking for. One that sounded quite well was an "omnidirectional" sealed column that I packed from the bottom up, first w/ a layer of pressed fiberglass ceiling tile, then fiberglass insulation, and finally some very light pillow stuffing around the driver area.

In those days I had no way of decently measuring the results, and there was no "Hornresp". I definitely don't want to go back to cut-and-try loudspeaker building, it is much more fun (and environmentally friendly) to simulate.

Anyway, the point I'm trying to make is that this highly resonant column sounded better when stuffed as described above, than when just lightly packed w/ an even density of e.g.: fiberglass.

I was wondering if you had any plans to further refine you software, to assign different airflow resistivities to different horn sections? It would indeed be a great feature.

Thank you very much for you efforts, and have a wonderful holiday season.

Regards,

Post #3962

Hi soongsc,

I found a pdf file that shows the prototype and the finished product reasonably well:

http://www.audiogamma.it/caricamenti/download/01_Nautilus_ctg.pdf

further descriptions are here:

Bowers & Wilkins - Nautilus Tapering Tubes

Regards,

Hi soongsc,

I found a pdf file that shows the prototype and the finished product reasonably well:

http://www.audiogamma.it/caricamenti/download/01_Nautilus_ctg.pdf

further descriptions are here:

Bowers & Wilkins - Nautilus Tapering Tubes

Regards,

Nice post tb46.

But other than the openended port for the mid, I don't really think that there is any really revolutionary engineering being accomplished.

Great industrial design and a leading active system sure. That I can really appreciate.

The last speaker design I did is active. An active speaker can do things that nothing else really has a chance of getting accomplished.

But other than the openended port for the mid, I don't really think that there is any really revolutionary engineering being accomplished.

Great industrial design and a leading active system sure. That I can really appreciate.

The last speaker design I did is active. An active speaker can do things that nothing else really has a chance of getting accomplished.

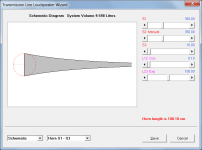

I think David did this as an simple exercise in studying the concept. He probably did not try to replicate the exact speaker enclosure.

Correct.

Hi Oliver,

Great minds think alike .

.

I have already started looking into the possibility...

Many thanks, and best wishes to you and yours also!

Kind regards,

David

I was wondering if you had any plans to further refine your software, to assign different airflow resistivities to different horn sections?

Great minds think alike

I have already started looking into the possibility...

Thank you very much for you efforts, and have a wonderful holiday season.

Many thanks, and best wishes to you and yours also!

Kind regards,

David

Well, I thought I would see somthing more convincingly show the marketing gimmic. Having seen pictures of the early concept exploration units, the idea seemed quite sound to me although I had not tried the concept. The test device actually showed a closed volume at the end of the sealed transmission line, not sure whether it was implemented in the final design.

At least get the dimensions to tuned to the driver in the sim, please.

Hi soongsc,

Because the tapered rear chamber is sealed, and filled with absorbent material, there is nothing to tune

There is no reflected wave - that is the whole purpose of including the absorbent material. The system is not operating as a transmission line loudspeaker, where the output from the lossy line is combined with the output from the front side of the driver. In the Nautilus design, the radiation from the rear side of the diaphragm is simply absorbed in the filling material and dissipated as heat.

The following quote from the Bowers & Wilkins brochure linked by Oliver is relevant:

"The combination of an acoustically transparent magnet and an exponentially tapered horn absorbs virtually all rearward radiation of sound - creating the nearest thing yet to an infinite baffle."

There is another interesting comment on the B&W web page, also linked by Oliver:

"Tapering the tube enables you to make it shorter for the same level of absorption. It acts like a horn in reverse - reducing the sound level instead of increasing it."

This statement is extremely misleading at best. The tapered tube is not acting as a "horn in reverse". Because the mouth is closed, it is acting as a sealed chamber. Also, tapering the chamber reduces the volume of the absorbent material for a given length. I can't see how this would improve the situation, where the B&W stated aim is to absorb the rearward radiation of sound.

The Bowers & Wilkins company makes very good loudspeakers, but I personally believe that the use of tapered exponential rear chambers in the Nautilus is more about achieving a "remarkable piece of audio sculpture" (their words) rather making a meaningful contribution to the sound quality.

This is just an opinion based on my understanding of the physics involved, and the evidence available to me. You are of course entitled to hold a different view

Kind regards,

David

Last edited:

First of all, as far as I can see, they use open end taper. Why would you use closed end and say B&W design is marketing hype? This is what I cannot understand. Just wanted to understand this. It is fine if you have an opinion, but when you are using technical analysis to support your opinion, please be prepared to accept criticism on the analysis. I am just saying the data does not seem to adequately support you opinion.Hi soongsc,

Because the tapered rear chamber is sealed, and filled with absorbent material, there is nothing to tune.

There is no reflected wave - that is the whole purpose of including the absorbent material. The system is not operating as a transmission line loudspeaker, where the output from the lossy line is combined with the output from the front side of the driver. In the Nautilus design, the radiation from the rear side of the diaphragm is simply absorbed in the filling material and dissipated as heat.

The following quote from the Bowers & Wilkins brochure linked by Oliver is relevant:

"The combination of an acoustically transparent magnet and an exponentially tapered horn absorbs virtually all rearward radiation of sound - creating the nearest thing yet to an infinite baffle."

There is another interesting comment on the B&W web page, also linked by Oliver:

"Tapering the tube enables you to make it shorter for the same level of absorption. It acts like a horn in reverse - reducing the sound level instead of increasing it."

This statement is extremely misleading at best. The tapered tube is not acting as a "horn in reverse". Because the mouth is closed, it is acting as a sealed chamber. Also, tapering the chamber reduces the volume of the absorbent material for a given length. I can't see how this would improve the situation, where the B&W stated aim is to absorb the rearward radiation of sound.

The Bowers & Wilkins company makes very good loudspeakers, but I personally believe that the use of tapered exponential rear chambers in the Nautilus is more about achieving a "remarkable piece of audio sculpture" (their words) rather making a meaningful contribution to the sound quality.

This is just an opinion based on my understanding of the physics involved, and the evidence available to me. You are of course entitled to hold a contrary view.

Kind regards,

David

Even a closed tube is not effective unless the 1/4 wavelength of the tube length frequency is in the bandwidth of the response. Not sure whether it is because you stuffed it too much or whether it is the driver.

With an open tube, yes, it can be shorter.

While I quite agree industrial design of the Nautilus taper was an important factor, but the roadmap shows that technical reasoning was just as important.

Are they misleading? I would say they are not telling the whole story. This is common practice in any industry. I could not get the whole truth even when buying a mobile phone.

Last edited:

First of all, as far as I can see, they use open end taper.

Hi soongsc,

I have been talking about the coiled "Nautilus shell" bass unit as shown in the original drawing posted by Oliver. It seems to me that is a sealed chamber. Do you have any evidence to suggest otherwise?

The high frequency configurations are definitely a marketing strategy. There is absolutely no need for such exotic rear enclosures (either open or closed). If however you wish to simulate one of the higher frequency units, then just leave the small end open, and look at Output 2 in the Loudspeaker Wizard (bearing in mind that there is a 2kHz upper frequency limit, for the reasons given in an earlier post).

Kind regards,

David

Attachments

All the experiment pictures in the PDF file shown in a previous post show the taper opening into another sealed volume. Although the total enclosure is closed, the transmission line part is open. If the research were done that way, is there any indication that the end product would be different?

I have expressed my question about speaker response vs transmission line length in your sim. However, I have no intention of doing a transmission line like that, rather, it would use side slots as mentioned before, and you have no intention of implementing that capability, so there is no point spending time on it. In fact, inspired by the Nautilus, I had a test unit implementing the configuration I mentioned, the results were positive for a test of concept.

I have expressed my question about speaker response vs transmission line length in your sim. However, I have no intention of doing a transmission line like that, rather, it would use side slots as mentioned before, and you have no intention of implementing that capability, so there is no point spending time on it. In fact, inspired by the Nautilus, I had a test unit implementing the configuration I mentioned, the results were positive for a test of concept.

Attachments

It is fine if you have an opinion, but when you are using technical analysis to support your opinion, please be prepared to accept criticism on the analysis. I am just saying the data does not seem to adequately support you opinion.

Soongsc, it is fine if you have an different opinion, but the data (or facts, rather) does not seem to support your critisism of the analysis

First of all, when you look at the pictures in the B&W brocnhure, there does not seem to be an opening at the small end of the curled tube for the bass section. The tubes for the higher freequency drivers may very well be open, but as I understand it, it was the bass section David analyzed.

I don't know if you believe anecdotal evidence, but a friend of mind saw the Nautilus speakers at a hifi show. He pushed the woofer inwards, and found to his surprise that it was a closed box design.

If neither of these arguments will do it for you, please consider the simulation of the Nautilus bass section done by Peter Fryer, head of research at B&W, in this JAES paper: AES E-Library Horn Acoustics: Calculation through the Horn Cutoff Frequency. The text for fig. 4 reads: "Predicted output with closed-end rear horn loading of Nautilus loudspeaker bass unit." If B&W head of research calls it a closed end rear horn, I'm not going to argue that the end is open

There is however one point regarding if it is a marketing gimmic or not. Or rather, if it has any value at all, because it is clearly good for marketing... And that is that a long, narrow, taprering tube will push all cross modes pretty high up in frequency, possibly out of the pass band of the driver. What is left is the end-to-end mode, which will be well damped by the stuffing. That may (or may not, due to the curling) be an improvement over an ordinary stuffed box.

Regards,

Bjørn

Bjørn, I have a friend that had a pair, I would not push on any of the drivers for fear that I might cause dents in them. From the looks of it, all of the drivers are closed end. The back end of the upper drivers seem to have a mechanism to pull them in. I have done a tapered and curled enclosure, just not closed and not as long as the Nautilus. Who else here has constructed and tested one?

My main point is, as originally stated, from the response of the simulation, the wrong dimensions were chosen for the driver. I asked for more information to try and figure out whether I was mistaken, and never got a reply. This seems to me my suspicion of the simulation conditions were probably correct. When we have all the information, then we will know.

I cannot seem to download the file you linked to, I guess I will have to see if I already have it somewhere. But as usual, we may never get the whole story until we actually test one.

Does it work? Well, my listening impression is that issues with the drivers are more dominant. So it is hard to tell.

My main point is, as originally stated, from the response of the simulation, the wrong dimensions were chosen for the driver. I asked for more information to try and figure out whether I was mistaken, and never got a reply. This seems to me my suspicion of the simulation conditions were probably correct. When we have all the information, then we will know.

I cannot seem to download the file you linked to, I guess I will have to see if I already have it somewhere. But as usual, we may never get the whole story until we actually test one.

Does it work? Well, my listening impression is that issues with the drivers are more dominant. So it is hard to tell.

Last edited:

First of all, as far as I can see, they use open end taper.

From the looks of it, all of the drivers are closed end.

Do you in the first quoute mean that they use a taper that opens up into a closed chamber? That seems to be the case with the prototype, but the chamber in the production model seems to be so small that there is no point in differentiating it from a closed end of a slightly longer tapered tube. At the frequencies in question, anyway.

My main point is, as originally stated, from the response of the simulation, the wrong dimensions were chosen for the driver.

So, you know what the right dimensions are?

I asked for more information to try and figure out whether I was mistaken, and never got a reply. This seems to me my suspicion of the simulation conditions were probably correct. When we have all the information, then we will know.

From post #3968, it is clear that David didn't want to simulate the actual design, just test the concept. And my understanding from post #3957 is that he just wanted to see if there was any difference between a tapered, filled duct and a simple filled box of the same volume. The dimensions and parameters of the driver and box are given in the post. You don't have to suspect anything about the simulation conditions, they are all given. If you believe changing the parameters would change David's conclusion, please do so and show us the results.

I have re-read your postings, and your questions are not very clear, so that's perhaps why they haven't been answered?

I cannot seem to download the file you linked to, I guess I will have to see if I already have it somewhere.

You have to pay for access to the AES e-library to download it, or you can purchase it ($5 for members, $20 for non-members). Otherwise, you just have to see if it is freely available somewhere else. But I've attached the figure in question FYI.

Bjørn

Attachments

Bjørn,

The literature on the Nautilus posted previously seems to indicate open end for at least the higher frequency drivers, what I can remember seeing was some sort of a hole in a metal part in the rear, cannot tell whether it goes through to the enclosure or not. It's been a few years since.

What a tapered tube does to the higher frequency waves is create a long reflection path so that it travels through the damping material longer before it will go back to the driver end. I think you can simulate is using a wave simulator. But the right length really depends on what kind of driver you are using. Mainly the reason why I asked about Fo which never got answered. I hope you are not expecting me to calculate myself. It was made clear the attempt was to see what the long coiled taper of the Nautilus was doing, but it seems the low end frequency response does not even come close to simulating a bass unit. Then calling the tapered tube a hype using simulation so carelessly is very unethical IMO. If you support that kind of stuff, good for you.

I only subscribe to AES once in a while, unfortunately I am not on it now.

Not all drivers are suitable for the Nautilus type taper tube. I tried to do it with a small driver, but could not get the volume vs length and taper to match up. You need to really try to find the right driver and work on it. B&W spent lots of time working on it just to be called a hype by someone who spent a little time on some software? Rediculouse! People not technical oriented may do that which is understandable, but you guys have lots more technical background than most around here...

I currently do not use hornresp simply because the capability is not what I was looking for. I may consider trying it out in the future, and will learn how to use it then.

Not interested in doing a tapered tube. Especially closed ones were never on my plan of research.

The literature on the Nautilus posted previously seems to indicate open end for at least the higher frequency drivers, what I can remember seeing was some sort of a hole in a metal part in the rear, cannot tell whether it goes through to the enclosure or not. It's been a few years since.

What a tapered tube does to the higher frequency waves is create a long reflection path so that it travels through the damping material longer before it will go back to the driver end. I think you can simulate is using a wave simulator. But the right length really depends on what kind of driver you are using. Mainly the reason why I asked about Fo which never got answered. I hope you are not expecting me to calculate myself. It was made clear the attempt was to see what the long coiled taper of the Nautilus was doing, but it seems the low end frequency response does not even come close to simulating a bass unit. Then calling the tapered tube a hype using simulation so carelessly is very unethical IMO. If you support that kind of stuff, good for you.

I only subscribe to AES once in a while, unfortunately I am not on it now.

Not all drivers are suitable for the Nautilus type taper tube. I tried to do it with a small driver, but could not get the volume vs length and taper to match up. You need to really try to find the right driver and work on it. B&W spent lots of time working on it just to be called a hype by someone who spent a little time on some software? Rediculouse! People not technical oriented may do that which is understandable, but you guys have lots more technical background than most around here...

I currently do not use hornresp simply because the capability is not what I was looking for. I may consider trying it out in the future, and will learn how to use it then.

Not interested in doing a tapered tube. Especially closed ones were never on my plan of research.

Last edited:

Sorry if I have offended you, Soongsc, but you must also be prepared to have your statements challenged.

It also surprises me how interested you are in accurately simulating a design you are not interested in, in a software you are not planning to use.

BTW, it is perfectly possible to simulate a stuffed, tapered tube in Hornresp, including the reflection from the far end, wether it is closed or not. What is not possible, is to take cross-modes into account, as the simulation is 1D. The main effects should be close, though.

Actually it's very simple: fs = 1/(2*pi*sqrt(Mms*Cms)). And Hornresp can do it with a few clicks. But since it turns out you are not using Hornresp, here it is: 51.6Hz.

And neither does B&W's simulation. But, again, this doesn't seem to have been the main point of David's simulation.

David, it seems that although you may not have offended a Nautilus owner, you have at least offended someone

Soongsc, if there was a real difference, I would have expected it to show up even in a simple simulation. Mind you, the simulation uses a model that closely resembles the one B&W used themselves, and their simulation shows the same as David's: Closed box behavior.

The rest of the paper is concerned with the theory of lossy exponential horns. The figure I showed is the only part that mentions Nautilus.

Wow, you really are offended! Just because a simulation of a design you are not interested in does not meet you expectations?

Well, we have some technical background, and that's perhaps why we don't swallow everything we read in a marketing brouchure. And I'm sure you don't swallow everything either. I don't doubt the B&W engineering department have spent many hours on this project. But so have the marketing people and industrial designers.

I don't believe that a full optimization, including finding the best driver etc, is necessary to test the concept. YMMV.

-Bjørn

It also surprises me how interested you are in accurately simulating a design you are not interested in, in a software you are not planning to use.

BTW, it is perfectly possible to simulate a stuffed, tapered tube in Hornresp, including the reflection from the far end, wether it is closed or not. What is not possible, is to take cross-modes into account, as the simulation is 1D. The main effects should be close, though.

Mainly the reason why I asked about Fo which never got answered. I hope you are not expecting me to calculate myself.

Actually it's very simple: fs = 1/(2*pi*sqrt(Mms*Cms)). And Hornresp can do it with a few clicks. But since it turns out you are not using Hornresp, here it is: 51.6Hz.

It was made clear the attempt was to see what the long coiled taper of the Nautilus was doing, but it seems the low end frequency response does not even come close to simulating a bass unit.

And neither does B&W's simulation. But, again, this doesn't seem to have been the main point of David's simulation.

Then calling the tapered tube a hype using simulation so carelessly is very unethical IMO. If you support that kind of stuff, good for you.

David, it seems that although you may not have offended a Nautilus owner, you have at least offended someone

Soongsc, if there was a real difference, I would have expected it to show up even in a simple simulation. Mind you, the simulation uses a model that closely resembles the one B&W used themselves, and their simulation shows the same as David's: Closed box behavior.

I only subscribe to AES once in a while, unfortunately I am not on it now.

The rest of the paper is concerned with the theory of lossy exponential horns. The figure I showed is the only part that mentions Nautilus.

You need to really try to find the right driver and work on it. B&W spent lots of time working on it just to be called a hype by someone who spent a little time on some software? Rediculouse! People not technical oriented may do that which is understandable, but you guys have lots more technical background than most around here...

Wow, you really are offended! Just because a simulation of a design you are not interested in does not meet you expectations?

Well, we have some technical background, and that's perhaps why we don't swallow everything we read in a marketing brouchure. And I'm sure you don't swallow everything either. I don't doubt the B&W engineering department have spent many hours on this project. But so have the marketing people and industrial designers.

I don't believe that a full optimization, including finding the best driver etc, is necessary to test the concept. YMMV.

-Bjørn

I have explored open taper tubes, and other lossy tube concept. I don't know what kind of work you have done in this area. But for the taper tube, if you want a better length, it would be about 1.7M for David's case. The software needs to be able to simulate enclosure modal pressure load on the driver if it does not already. Then the kind of taper and length needs to be adjusted from there. This is what I do for open tapers and lossy tubes. Due to the irregular shapes I like to use, if there were existing software to handle most of the work, it would be great. Now, lots of benefits are in the higher frequencies, so if the software cannot simulate internal reflections effects, you will not see such differences.

I continue to monitor this thread because I hope to see the capability I want implemented. If it evolves to a point that fits into part of what I am doing, at any time, then I would spend more time to try it out.

I do get very upset when one engineer criticizes hard work of others by using poor data with very little knowledge on the subject. It is fine if it is just an opinion without data, but once you present the data, just be prepared to answers to it. Nothing personal.

I see the Nautilus curve you provided, but I have no idea what the length of the tube is. If you do not know this, how can you replicate what they are doing? It is necessary to inspect the relating driver parameters and the design to figure out how to replicate something similar. So what horn cutoff frequency is Dave's taper pattern supposed to be?

Yes, if I use data to prove others wrong, I am prepared to hold myself to same criticism. If others also show data that are conflicting with mine, I hope both are prepared to explore the possible causes of differences openly. Even if I might be wrong in the end, I will have learned something. Can't lose.

I continue to monitor this thread because I hope to see the capability I want implemented. If it evolves to a point that fits into part of what I am doing, at any time, then I would spend more time to try it out.

I do get very upset when one engineer criticizes hard work of others by using poor data with very little knowledge on the subject. It is fine if it is just an opinion without data, but once you present the data, just be prepared to answers to it. Nothing personal.

I see the Nautilus curve you provided, but I have no idea what the length of the tube is. If you do not know this, how can you replicate what they are doing? It is necessary to inspect the relating driver parameters and the design to figure out how to replicate something similar. So what horn cutoff frequency is Dave's taper pattern supposed to be?

Yes, if I use data to prove others wrong, I am prepared to hold myself to same criticism. If others also show data that are conflicting with mine, I hope both are prepared to explore the possible causes of differences openly. Even if I might be wrong in the end, I will have learned something. Can't lose.

Last edited:

- Home

- Loudspeakers

- Subwoofers

- Hornresp