Is there a place where Hornresp list vent air velocity when simulating a ported enclosure?

Hi Mark,

Currently Hornresp does not provide details of port air velocity. I guess it would not be too difficult to add the information to the Sample tool results when the port SPL chart is displayed, if the need was considered great enough.

Note however that Hornresp port air velocities would in most cases be higher than WinISD values because losses are not taken into account in Hornresp, as Bjørn has mentioned.

Kind regards,

David

What if Hornresp could crunch the numbers of multiple records? That is to say that if you created a file for each position along the path where a driver is located. It would also be interesting if you could use another mode of the multiple record technique for comparison.

Hi Dan,

Sorry, it's not going to happen - too much work required

Kind regards,

David

Hi Mark,

Currently Hornresp does not provide details of port air velocity. I guess it would not be too difficult to add the information to the Sample tool results when the port SPL chart is displayed, if the need was considered great enough.

Note however that Hornresp port air velocities would in most cases be higher than WinISD values because losses are not taken into account in Hornresp, as Bjørn has mentioned.

Kind regards,

David

I know two things for sure.

If it was there I would use it.

And second. If I am guessing this correctly the amount of coding to exceed the accuracy of WinISD is not to far out of your reach. If you added a option for accurate vent air velocity it would prove to be very useful for more than just a port in a box. Knowing the air speed in a horn near the throat is also very useful.

Mark

If I am guessing this correctly the amount of coding to exceed the accuracy of WinISD is not to far out of your reach. If you added a option for accurate vent air velocity it would prove to be very useful for more than just a port in a box.

Hi Mark,

I am not sure how useful port air velocity values generated by Hornresp would really be. I guess they could be considered "worst case" in that they would normally be higher than those calculated by WinISD, but this does not necessarily mean that they would be any more accurate.

For valid comparisons with WinISD port air velocity results, Hornresp would need to be set to the unmasked resonances option and the WinISD enclosure leakage loss value Ql would have to be made very large - typically around 999999.

I suspect that differences in the values generated by the two programs depending upon the input conditions could be a source of confusion for some users, so perhaps it is better not to include the feature in Hornresp at all

WinISD should be accurate enough for practical purposes, I would have thought.

(Hornresp records can of course be exported to AkAbak and volume velocites calculated there, with port air velocity being derived by dividing port volume velocity by port cross-sectional area).

Kind regards,

David

Last edited:

Hello David

WinISD is quite good.

What I have been working on as of late is a small horn where I am worried what the air speed velocities will be.

Horn's tend to distort quite badly when pushed beyond a certain limit.

Packing up is what we used to call it when I play a French Horn. You can blow harder but no greater amount of useable sound will be emitted.

If something could be accomplished by this request to try and determine air speed velocities then great.

If it is to esoteric or to difficult, then I asked, and you gave a gracious answer.

I have to say this. That without this program much of what I try to accomplish would be a great deal more difficult.

Many thanks David.

WinISD is quite good.

What I have been working on as of late is a small horn where I am worried what the air speed velocities will be.

Horn's tend to distort quite badly when pushed beyond a certain limit.

Packing up is what we used to call it when I play a French Horn. You can blow harder but no greater amount of useable sound will be emitted.

If something could be accomplished by this request to try and determine air speed velocities then great.

If it is to esoteric or to difficult, then I asked, and you gave a gracious answer.

I have to say this. That without this program much of what I try to accomplish would be a great deal more difficult.

Many thanks David.

If something could be accomplished by this request to try and determine air speed velocities then great.

Hi Mark,

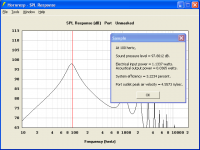

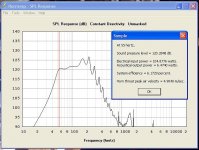

Air velocity details will be included in the SPL response chart Sample tool in the next release of Hornresp, due in the next few days.

Kind regards,

David

Attachments

Is it applicable globally or in the vented box section only?

Hi Mark,

It will apply globally - to all SPL response charts except for the combined response chart itself.

Kind regards,

David

Hornresp Update

Hi Everyone,

Air velocity is now included in the SPL response chart sample results. Product Number 2850-110727 refers.

Please note that for a valid comparison with WinISD port air velocity results, Hornresp should be set to the unmasked resonances option and the WinISD enclosure leakage loss value Ql must be made very large - typically around 999999.

My thanks to Mark for raising the issue of air velocity.

Kind regards,

David

Hi Everyone,

Air velocity is now included in the SPL response chart sample results. Product Number 2850-110727 refers.

Please note that for a valid comparison with WinISD port air velocity results, Hornresp should be set to the unmasked resonances option and the WinISD enclosure leakage loss value Ql must be made very large - typically around 999999.

My thanks to Mark for raising the issue of air velocity.

Kind regards,

David

I'm thinking that this will end up being a very powerful piece of Hornresp.

Hi Mark,

Could you please let me know in due course if you do find the information to be useful, and if so, how it influences your horn design considerations. Many thanks.

Kind regards,

David

Me post test results? When?

I promise David. I have always posted test results. The problem with this concept is going to be able to measure the air flows.

Maybe there is a low enough cost anemometer that is USB plug-able or something like that.

Because I would really like to know when and at what power level I can design a horn path to reach a SPL point without packing up. If I could do that with the same degree of confidence that the rest of your program has given me....

Muhahahhaaaaa Rubbing hands together.....

One last question if you don't mind.

You have made reference to some of your work starting away back when. You have made reference to starting the Hornresp program on punch cards.

Mind me asking how old you are David?

Because you are one very productive gentleman. And I'm certain that you are older than I by quite a piece.

I remember punch cards. I never used then as there were the medium sized floppies when I took computer science.

I promise David. I have always posted test results. The problem with this concept is going to be able to measure the air flows.

Maybe there is a low enough cost anemometer that is USB plug-able or something like that.

Because I would really like to know when and at what power level I can design a horn path to reach a SPL point without packing up. If I could do that with the same degree of confidence that the rest of your program has given me....

Muhahahhaaaaa Rubbing hands together.....

One last question if you don't mind.

You have made reference to some of your work starting away back when. You have made reference to starting the Hornresp program on punch cards.

Mind me asking how old you are David?

Because you are one very productive gentleman. And I'm certain that you are older than I by quite a piece.

I remember punch cards. I never used then as there were the medium sized floppies when I took computer science.

Mark,

I am not sure if what we have been seeing is due to air velocities or not. I was thinking it could be related to that or, pressure, force or even acceleration perhaps. Maybe a combination. Another thing is how do we know it is happening at the throat. It makes sense that the highest stresses on the system and air inside the horn are there, but you never know.

Thanks for the addition David.

I am not sure if what we have been seeing is due to air velocities or not. I was thinking it could be related to that or, pressure, force or even acceleration perhaps. Maybe a combination. Another thing is how do we know it is happening at the throat. It makes sense that the highest stresses on the system and air inside the horn are there, but you never know.

Thanks for the addition David.

A little thinning

Velocity ends up being a function of speed of the air. If you have speed and a known volume of displacement off of the driver you can calculate the air pressure. That pressure of course diminishes as you go further down the horn path length. It should not be that difficult to calculate the pressure drop when you are down the path length of the horn.

My guess is that when a horn packs up the air pressure is too great. Therefore we get the distorted output. What has to be done now is the measurements and simulations.

What is to great of an air pressure or air velocity I do not pretend to know.

But I think that a little experimentation should be able to get some of those answers.

Mark

Velocity ends up being a function of speed of the air. If you have speed and a known volume of displacement off of the driver you can calculate the air pressure. That pressure of course diminishes as you go further down the horn path length. It should not be that difficult to calculate the pressure drop when you are down the path length of the horn.

My guess is that when a horn packs up the air pressure is too great. Therefore we get the distorted output. What has to be done now is the measurements and simulations.

What is to great of an air pressure or air velocity I do not pretend to know.

But I think that a little experimentation should be able to get some of those answers.

Mark

My guess is that when a horn packs up the air pressure is too great. Therefore we get the distorted output. What has to be done now is the measurements and simulations.

Mark, I want to throw out an alternate thought for you based on some of my mcm experiments. The exact same area (50cm2) in a 1/2" x 8" vs in a 2"x4" area sound COMPLETELY different, and when pushed the 1/2" x 8" 'packs up' as you call it, where the 2x4 doesn't.

Air speed may be one thing to be aware of, but I'm thinking that air friction (if that's the right description) may be even more relevant in small horns. Where hornresp doesn't take losses into consideration, I don't think there is a good way to model what I observed with the mcm's.

Thanks for the addition david.

More food for thought:

Is it a question of pressure over the cone or an area away from the cone where there is actually turbulence?

If I can take this one more step.

I'm thinking that in a well designed, linearly operating horn we have laminar air flow.

If that statement is correct then what is happening when a horn is over driven?

Is it a function of flow patterns?

As in an area where there is so much turbulence that is creates a type of stopper effect? A small high pressure area within the horn path where we get effectively a dead spot in the horn path?

Or are we pushing a driver to the point of non-linearity and we suffer the natural effects of oil canning?

A view port could prove or disprove that idea ( oil canning ) quite easily.

I have a Baumer laser distance measurement thingy magigy. I could insert it into a horn and measure the driver displacement as the distortion goes up.

The only part that is a little more difficult is finding a microphone that will survive the SPL close to the horns throat. I really don't know how loud it is that close. But I know that most horns are well above 100db at one meter before they start to misbehave.

Maybe a panasonic cartridge with the Linkwitz high SPL mod would survive. I have a few of those to give a shot at it with.

Still don't have an idea for the actual velocity measurement.

Crazy anemometers are not that cheap.

Oh well this kind of stuff never stopped me before.

It just slows me down for a while!

Mark, I want to throw out an alternate thought for you based on some of my mcm experiments. The exact same area (50cm2) in a 1/2" x 8" vs in a 2"x4" area sound COMPLETELY different, and when pushed the 1/2" x 8" 'packs up' as you call it, where the 2x4 doesn't.

Is it a question of pressure over the cone or an area away from the cone where there is actually turbulence?

If I can take this one more step.

I'm thinking that in a well designed, linearly operating horn we have laminar air flow.

If that statement is correct then what is happening when a horn is over driven?

Is it a function of flow patterns?

As in an area where there is so much turbulence that is creates a type of stopper effect? A small high pressure area within the horn path where we get effectively a dead spot in the horn path?

Or are we pushing a driver to the point of non-linearity and we suffer the natural effects of oil canning?

A view port could prove or disprove that idea ( oil canning ) quite easily.

I have a Baumer laser distance measurement thingy magigy. I could insert it into a horn and measure the driver displacement as the distortion goes up.

The only part that is a little more difficult is finding a microphone that will survive the SPL close to the horns throat. I really don't know how loud it is that close. But I know that most horns are well above 100db at one meter before they start to misbehave.

Maybe a panasonic cartridge with the Linkwitz high SPL mod would survive. I have a few of those to give a shot at it with.

Still don't have an idea for the actual velocity measurement.

Crazy anemometers are not that cheap.

Oh well this kind of stuff never stopped me before.

It just slows me down for a while!

In the few horns that I have measured I can rule out driver excursion or oil canning. The plateau in output never occurs where there is a lot of excursion or even in the first octave of the useful response. Just from looking at some simulation data compared with the real world results the air velocity doesn't seem to match up that well either. In horns there is a pattern of high velocity and low velocity movement that will follow the driver displacement roughly. The plateau in horn output only appears in certain frequency ranges in my few limited tests and they don't seem to correspond well with a velocity or excursion maximum either one.

I think I have to make me a test horn. Preferably a straight one that I can do some performance work on.

I put out some feelers to suppliers of anemometers. Will see what I end up with.

I tend to agree with you Josh that the distortion effects are not due to driver over excursion. That is as long as the signal is within the passband of the horn.

This should prove to be interesting to say the least.

I don't know if there are any papers on the subject.

Time to get a digging.

Mark

I put out some feelers to suppliers of anemometers. Will see what I end up with.

I tend to agree with you Josh that the distortion effects are not due to driver over excursion. That is as long as the signal is within the passband of the horn.

This should prove to be interesting to say the least.

I don't know if there are any papers on the subject.

Time to get a digging.

Mark

Mind me asking how old you are David?

Hi Mark,

Without giving too much away - I am old enough to have been happily retired for a number of years

Kind regards,

David

- Home

- Loudspeakers

- Subwoofers

- Hornresp