A 4 segment TH2 tapped horn has driver entry points at S3 and S4

Hi epa,

Thanks for the clarification - your original statement makes perfect sense now

Unfortunately it would require a lot of work to fully integrate the proposed option into Hornresp - the simulation model, schematic diagram, Loudspeaker Wizard, Wavefront Simulator, etc, would all need changing. The Loudspeaker Wizard in particular would require significant internal modifications.

In view of the presumably limited application of the option, another one probably best left to AkAbak!

That's a long-winded way of me saying, "sorry, it's not going to happen"...

Kind regards,

David

ive heard that one beforeHi epa,

"sorry, it's not going to happen"

Kind regards,

David

its not that important ,it was just a model i was working on.

tnx anyway for the beautiful program you gave us

I compared exactly the same thing as last time.

Let me know if you need anything else.

Hi just a guy,

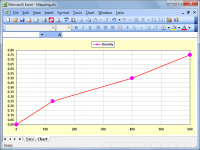

Many thanks for this. It is very interesting indeed that the relationships seem to hold up reasonably well. Can MJK's software accept densities other than the three used so far in the comparisons? It would be nice to be able to add a few more data points to the attached chart, so that a more complete conversion mapping can be developed.

What I am thinking is, that if the MJK empirically-derived densities actually do apply accurately in the real world, then the Hornresp Loudspeaker Wizard could easily calculate and display the weight in kilograms of PolyFill material required to achieve a given resistivity value for a given system.

For example, if the flow resistivity value required is 400 mks rayls/m and the filled volume of the enclosure happens to be 358.871 litres (as in the latest example) then 2.87 kilograms of Polyfill material should be used.

400 mks rayls/m ~ 0.5 lb/ft3

0.5 lb/ft3 ~ 8.009 g/litre

358.871 litres ~ 2.87 kg

Kind regards,

David

Attachments

ive heard that one before

its not that important ,it was just a model i was working on.

tnx anyway for the beautiful program you gave us

Can MJK's software accept densities other than the three used so far in the comparisons?

Yes, you can enter any number you like, including decimals. I don't usually use more than 3 decimal places but you can probably get REALLY fractional if you needed to.

It would be nice to be able to add a few more data points to the attached chart, so that a more complete conversion mapping can be developed.

Tell me exactly what you need and I'll get to work on it asap.

What I am thinking is, that if the MJK empirically-derived densities actually do apply accurately in the real world, then the Hornresp Loudspeaker Wizard could easily calculate and display the weight in kilograms of PolyFill material required to achieve a given resistivity value for a given system.

For example, if the flow resistivity value required is 400 mks rayls/m and the filled volume of the enclosure happens to be 358.871 litres (as in the latest example) then 2.87 kilograms of Polyfill material should be used.

400 mks rayls/m ~ 0.5 lb/ft3

0.5 lb/ft3 ~ 8.009 g/litre

358.871 litres ~ 2.87 kg

Kind regards,

David

Sure, MJK's software even gives a summary at the end of the user inputs before the calculations starts that lets the user know how much total stuffing is needed.

An externally hosted image should be here but it was not working when we last tested it.

The problem here, as I've mentioned at least a couple of times, is that the two programs calculate some things differently so it's hard for me to tell exactly how much stuffing in Hornresp is equal to the amount of stuffing in MJK's. And I don't want to be responsible for making that call. Clearly my guessing is in the right ballpark but it's not a perfect match.

If you want I can send a whole bunch of graphs of the same tl(s) with many different stuffing levels (a lot more than 0, .25, .5 and .75 lb/ft) and you can make the judgment on what value of mks rayls/m = a given density of stuffing in lb/ft or kg/m or whatever.

One final note - MJK warns that once you get past 1 lb/ft, his software predictions might get unreliable. I don't think he tested past that level, and if he did he probably got unfavorable results. There's not much need to stuff any denser than that anyway or the stuffing is going to turn into a solid mass, but just thought you might like to know.

EDIT - one more final note on this. For .5 lb/ft stuffing in the last example, MJK reports 6.6887 lb total, which my conversion program says is 3.123891 kg. Your calculation was 2.87 kg. I don't know what segment type MJK uses, but if he uses PAR, that could account for the difference (both comparisons I did used CON segments for the Hornresp part). I just assumed MJK was using CON segments, everyone was back when the worksheets were made.

Or the difference could be due to something else. Whatever the difference is, perhaps we should find out before proceeding.

Last edited:

I realize that, I wouldn't be able to provide these simulations if I didn't have it. Mathcad just calculates whatever you tell it to. Are you saying mathcad is inaccurate or is there another reason for this comment? Because I'm confused, people usually call it MJK's Mathcad worksheets, so this seems incredibly obvious.

I just wanted David to be aware that MathCad has been around since probably Windows 3 or earlier. Calculating algorithms should be pretty mature. I have used early MJK worksheets, and they work pretty well and flexible. If I recall correctly, Martin did lots of testing and compared against his calculations. Since he did not have to hard code most of the math, coding was probably easier as long as MathCad did it's job.

Hi just a guy,

That would be excellent - many thanks!

If charts can be generated using filling densities from 0.00 lb/ft3 through to 1.00 lb/ft3 in 0.05 lb/ft3 increments, for each of the two test examples we have been considering, then that would be brilliant. We are talking here about a total of 42 charts though, which may be too much of an ask... .

.

Anything you can do could be zipped up and sent to my email address, if convenient.

Thanks for the "heads up".

Based on his volume formulas, it seems that MJK is using Par segments.

Changing our second test example from Con to Par segments increases the Hornresp system volume from 358.871 litres to exactly 390.000 litres. This changes the filling requirement from 2.87 kg to 3.12 kg, which is the same as your figure.

Thanks again for your ongoing assistance with this exercise, it is greatly appreciated.

Kind regards,

David

If you want I can send a whole bunch of graphs of the same tl(s) with many different stuffing levels (a lot more than 0, .25, .5 and .75 lb/ft) and you can make the judgment on what value of mks rayls/m = a given density of stuffing in lb/ft or kg/m or whatever.

That would be excellent - many thanks!

If charts can be generated using filling densities from 0.00 lb/ft3 through to 1.00 lb/ft3 in 0.05 lb/ft3 increments, for each of the two test examples we have been considering, then that would be brilliant. We are talking here about a total of 42 charts though, which may be too much of an ask...

Anything you can do could be zipped up and sent to my email address, if convenient.

One final note - MJK warns that once you get past 1 lb/ft, his software predictions might get unreliable. I don't think he tested past that level, and if he did he probably got unfavorable results. There's not much need to stuff any denser than that anyway or the stuffing is going to turn into a solid mass, but just thought you might like to know.

Thanks for the "heads up".

For .5 lb/ft stuffing in the last example, MJK reports 6.6887 lb total, which my conversion program says is 3.123891 kg. Your calculation was 2.87 kg.

Based on his volume formulas, it seems that MJK is using Par segments.

Changing our second test example from Con to Par segments increases the Hornresp system volume from 358.871 litres to exactly 390.000 litres. This changes the filling requirement from 2.87 kg to 3.12 kg, which is the same as your figure.

Thanks again for your ongoing assistance with this exercise, it is greatly appreciated.

Kind regards,

David

We are talking here about a total of 42 charts though, which may be too much of an ask....

Are you kidding me? How much time did you spend making this program that I use ALL THE TIME? I'm sure I can find the time to help you make it even better. It should only take an hour or two, it's no problem at all.

It shouldn't need to be zipped, I'm just going to send 4 pictures, probably around 1 or 2 Mb total. 2 pictures showing each example's entire worksheet screenshot (so you can verify I'm doing it right) and 2 pictures showing each example's 21 levels of stuffing graphs.

I thought the difference might be due to PAR segments, so that part is up to you now. I have no options in MJK's software, you'll have to switch your Hornresp sims to PAR.

I'll capture the graph that shows the individual driver and terminus output for you instead of the combined output. I'll also label each graph with amount of stuffing (in lb/ft) and the total amount of stuffing in the line (in lb).

Hopefully it will be in your inbox tonight, I'm going to start working on it now. Hopefully I won't be interrupted too much and I can finish it all today.

Done and sent.

Hi just a guy,

Excellent. The information you have provided is just what I was looking for. Many thanks.

Kind regards,

David

an extremely helpful feature to have, would be the ability to view how Power Compression alters various factors.

Hi Zero D,

Hornresp would need to know the temperature of the voice coil, and how Re varies due to changes in voice coil temperature. This information is not available to the program. Did you perhaps have a simpler alternative method in mind, for calculating power compression?

Kind regards,

David

@ David McBean

I'll give it further thought, but in the meantime i found these which "might" prove useful to you, in some ways ?

I'll give it further thought, but in the meantime i found these which "might" prove useful to you, in some ways ?

Power Compression Efficiency, Power Compression & Max SPL | Audioholics

Loudspeaker Power Handling Vs. Efficiency Power Handling Vs. Efficiency

Simulation of voice coil temperature and compression at high power Prism Sound: LOUDSOFT - FINEBox

Hi Mark and Zero D,

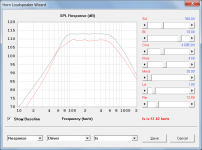

Thanks for the links. They confirm that the calculation of power compression is not a trivial exercise. It is simple enough though, to demonstrate the effect without knowing absolute values by substituting 2 * Re for Re and observing how the SPL response, diaphragm displacement, etc, change.

The attached example shows the Hornresp default record with Re increased from 6 ohms to 12 ohms.

Kind regards,

David

Thanks for the links. They confirm that the calculation of power compression is not a trivial exercise. It is simple enough though, to demonstrate the effect without knowing absolute values by substituting 2 * Re for Re and observing how the SPL response, diaphragm displacement, etc, change.

The attached example shows the Hornresp default record with Re increased from 6 ohms to 12 ohms.

Kind regards,

David

Attachments

- Home

- Loudspeakers

- Subwoofers

- Hornresp