for this one I used as dima (drill guide) this mm paper http://lnx.edsdidact.it/shop/images/294.jpg

quite precise at the end,at last for my standard ))

))

quite precise at the end,at last for my standard

Attachments

An externally hosted image should be here but it was not working when we last tested it.

This is the model of a TigerI, for which i won a prize for its ZIMERIT. Instead stucko, i made the zimerit by melting the plastic surfaces with a modified soldering tip.

Ha ha.

Down here we play with the real thing. Here is a screen shot of a home video a mate took, out on the farm. It's a 50,000kg British Centurion with a RR Merlin engine, ex Vietnam. Bought ex-army surplus; a decent amount a machinery for only $14,000 AUD, I think he said it was.....

Attachments

Thanks , I drill only, fine I will use this ,

some time 3.5mm hole is perfect size,we can put 3mm screw, or tapping for 4mm screw or live as is

As I jump from SS to tube ,what suggest for big hole ? Punch?

Dear nico, milling cutters are specific tools. Are not for drilling simple holes for screws. For this purpose the common HSS drills are preferable because have nose tip which can centralized in punched centers. Instead a slot drill has a flat cutting surface which can't centralized. Of course you can use a slot drill yet with a drill press providing that the workpiece it is tightened securely on the support table. To make the thing short, it is waste of time to open screw holes using milling cutters. Moreover, if the workpiece has a thickness from 2mm and above, then yet a common drill bit can open a perfect round hole.

I use milling cutters only for such works like the ventilation holes or for opening holes for buttons, LEDs, switches etc on the front panel. Also, for cutting square holes.

For big round holes it is preferable the use of HOLE CUTTERS with a drill press. If you look at the picture of the rear panel of my amplifier, i did the holes for the XLR sockets with a hole cutter of Φ22mm at the drill press.

You must not forget two things for a good result:

1) Good tightness of workpiece on the support table to stay stable during drilling

2) For cutting or drilling aluminum sheets the use of diesel oil for lubricating the cutter to not melt the aluminum. For metal sheet drilling you must use for lubricating a mix of: a) 80% water b) 10% thin motor oil (say SAE10W) c) 10% common soap. This prevents the damage of drill bit due to overheating.

Fotios

for this one I used as dima (drill guide) this mm paper http://lnx.edsdidact.it/shop/images/294.jpg

quite precise at the end,at last for my standard))

From this picture, it is obvious that you are an excellent machinist.

Your project as well it is very nice, and implemented with Hi-End class parts like the Cornell-Doubilier Silver Mica capacitors.

My compliments sir!

Fotios

Hey, Dr. RAVEN, my Friend!

I ponder on the fact that it would be possible to keep a vote for a while already, which one the most beautiful diy amplifier.

But you my friend you may not attend this.

A pro is not eligible between the amateurs.

Gyuri

I ponder on the fact that it would be possible to keep a vote for a while already, which one the most beautiful diy amplifier.

But you my friend you may not attend this.

A pro is not eligible between the amateurs.

Gyuri

An externally hosted image should be here but it was not working when we last tested it.

I have reported this attachment.

Hi all Moderators,

there must be something wrong with the way the upgraded Forum is using attachments.

This 5.8Mb pic had to download before I can see what is happening.

We the readers cannot stop it downloading.

The Forum should not allow anything bigger than 100k to download automatically.

We the Members should have control over what we want to download.

In addition this particular download has an enormous blank space around the re-sized pic. Is this to allow room for the full size pic?

Can you please sort this aspect of the Forum.

All automatic downloads should be restricted to <=100kb and the option to look at or download anything bigger, whether from a separate server or not, must be in the control of the individual members to suit what they can download conveniently via their chosen ISP and bandspeed and what they need to look at.

Please discuss this and come to a conclusion that is better than what we are saddled with at present.

regards

Andrew T.

Well, the trouble is with me again already.

Anyway the remark totally legitimate, slow contact this may be terrible. On other sides gave up the picture links' insert. This slipped in now, excuse me.

It is necessary to manage to solve that the person who is curious about it possibly should download the full-size picture only.

It lightened up possibly otherwise, I cannot decide it, the picture, or the sound recording more important for me. This question like that, which child of mine I love better?

Or what would be badder, if become deaf, or if go blind.

Sorry.

Gyuri

Anyway the remark totally legitimate, slow contact this may be terrible. On other sides gave up the picture links' insert. This slipped in now, excuse me.

It is necessary to manage to solve that the person who is curious about it possibly should download the full-size picture only.

It lightened up possibly otherwise, I cannot decide it, the picture, or the sound recording more important for me. This question like that, which child of mine I love better?

Or what would be badder, if become deaf, or if go blind.

Sorry.

Gyuri

The last question is an academician totally because the answer is trivial entirely.

If I go blind, better, if the sound recording is my favourite hobby.

If I become deaf, better, if the picture recording is my favourite.

Well, the train is left if both scripts come in.

Wacky Gyuri

Anyway increasingly deafer and blinder I am.

If I go blind, better, if the sound recording is my favourite hobby.

If I become deaf, better, if the picture recording is my favourite.

Well, the train is left if both scripts come in.

Wacky Gyuri

Anyway increasingly deafer and blinder I am.

Last edited:

Hey, Dr. RAVEN, my Friend!

I ponder on the fact that it would be possible to keep a vote for a while already, which one the most beautiful diy amplifier.

But you my friend you may not attend this.

A pro is not eligible between the amateurs.

Gyuri

Thank you Gyuri

I don't need vote for my projects. Especially YOU know that i make this work to i live, to i earn my daily bread; and not for the purchase of a luxury car!

Except that i have an inborn artistic view in constructions, for the rests i am not better from the rest people who design audio circuits. I haven't any innovation in the circuitry of my amplifier. Simply i as well and some other members, we don't stay only in theoretical approximations, drawing schematics, SPICE simulations etc. We have the courage to implement in practice what we have designed in the paper. You know very well that i am as well perfectionist, stubborn and i have big patience; thus my projects presented in the eyes of people beautiful. I don't have any intention to cause impression at people purposely. I make my projects in such a way, so they can impress only myself. Like a picture painting. The rest they come in a natural manner.

Fotios

Thanks so much Fotios for encourage , as this my first serius try on alu ,before I work only on wood.....

Very usefull your suggestion

The amp is nice E.Borbely mosfet ,dale,rifa, nichicom gold,toshiba jfet ,hitachi/reneas mosfet

Be my guest nico!

Fotios

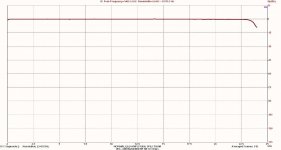

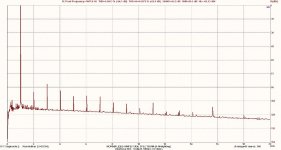

Some measurements of charisma 0k6

Measurements of amplifier output driving a dummy load of 8Ω with 1Wrms. Software used is the Virtins M.I. Pro3.1 via a Sound Blaster X-Fi Platinum. The sampling rate of sound card was 48KHz and the bit depth 24bit.

Fotios

Measurements of amplifier output driving a dummy load of 8Ω with 1Wrms. Software used is the Virtins M.I. Pro3.1 via a Sound Blaster X-Fi Platinum. The sampling rate of sound card was 48KHz and the bit depth 24bit.

Fotios

Attachments

Last edited:

People are really different...i have loved that huge image Gyuri have posted...

even beeing an outlaw image was lovely to see all the details,

I could see details, dust, cucaroach excrement, hairs, fingerprints and lovely equipment...i could read "sztereo"...lovely that.

I wish all picture could be this way..better if pictures could be a panoramic , or some 360 degrées landscape to see all the room surroundings... better if some kind of three dimensional vision, or a stereo vision having 250 Megabytes each image..the same resolution we have in human eyes.

I love images, so much as audio and food!

regards,

Carlos

even beeing an outlaw image was lovely to see all the details,

I could see details, dust, cucaroach excrement, hairs, fingerprints and lovely equipment...i could read "sztereo"...lovely that.

I wish all picture could be this way..better if pictures could be a panoramic , or some 360 degrées landscape to see all the room surroundings... better if some kind of three dimensional vision, or a stereo vision having 250 Megabytes each image..the same resolution we have in human eyes.

I love images, so much as audio and food!

regards,

Carlos

Attachments

Last edited:

even beeing an outlaw image was lovely to see all the details,

I could see details, dust, cockroach excrement, hairs, fingerprints and lovely equipment...i could read "sztereo"...lovely that.

I wish all picture could be this way..better if pictures could be a panoramic , or some 360 degrées landscape to see all the room surroundings... better if some kind of three dimensional vision, or a stereo vision having 250 Megabytes each image..the same resolution we have in human eyes.

I love images, so much as audio and food!

regards,

Carlos

Hi Karolos

Gyuri is an amazing guy. I know Gyuri very well. We are very good friends (through the net of course) and we exchange mails or messages very often. Gyuri is a very polite and intellectual man. He is an amazing good man. I consider him like a brother. Of course i consider and you as very good man and a friend of me. But Gyuri is another story!

As for his rest audio stuff, it is of amazing quality. But Gyuri is very modest (due to his politeness) to cause needless noise. He has as well a big music culture which is a family legacy to him.

Gyuri has the same problem with me; he and i, we are self-taught in English language.

I hope some day to meet with him (as well with you) from close.

LUCIO

P.S. Forgive me for that i don't get you in my friends on this forum. I will do that immediately.

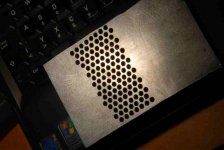

Aluminium drilling

Dear Fotios!

I need your opinion.

I love it onto the idiotic one his pierced cover your amplifier.

Exceptionally precise, just like the rest of his parts for the thing.

But for me only single old B&D I have a drill, with a rack.

I took from my primary payment yet, before with 32 years.

That's right, we are old old men like this.

Let the deuce take it.

Oh now if I do not guide it the drill stem, crawls away into that goddamn aluminium the drill stem. The component of the mincer than drill scheme

may it be a solution?

Let my wife not find it out by the time I use her mincer only.

I desire to you a beautiful day:

Gyuri

Dear Fotios!

I need your opinion.

I love it onto the idiotic one his pierced cover your amplifier.

Exceptionally precise, just like the rest of his parts for the thing.

But for me only single old B&D I have a drill, with a rack.

I took from my primary payment yet, before with 32 years.

That's right, we are old old men like this.

Let the deuce take it.

Oh now if I do not guide it the drill stem, crawls away into that goddamn aluminium the drill stem. The component of the mincer than drill scheme

may it be a solution?

Let my wife not find it out by the time I use her mincer only.

I desire to you a beautiful day:

Gyuri

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Aluminium drilling

For beginning not bad. Only enough exhausting, and not enough efficient.

So that for you, Fotios, I do not recommend it because you starve to death if you do it so.

But this here DIY, because of this allowable the mincer method.

Gyuri

For beginning not bad. Only enough exhausting, and not enough efficient.

So that for you, Fotios, I do not recommend it because you starve to death if you do it so.

But this here DIY, because of this allowable the mincer method.

Gyuri

Attachments

I love it - that is just great!...the mincer method.

- Home

- Amplifiers

- Solid State

- Post your Solid State pics here