A dead Hafler XL-280. Two exploded 470uF caps hidden away in the power supply board. A completed repair using a Musical Concepts PS-200M power supply board. Great kit, instructions could use improvement, but overall a very good experience. Best part: after I got done with the repair the amp actually turned on and didn't burst into flames. Then I hurt my shoulder trying to pat myself on the back.

I've just checked DC offset and found 7.2mV on one channel, but -32mV on the other channel. There's no bias or offset adjustment procedure shown in the assembly manual. Each input board has an adjustable capacitor for the Excelinear circuit, and a mystery pot a few inches away.

What are the adjustment procedures for this amp?

I've just checked DC offset and found 7.2mV on one channel, but -32mV on the other channel. There's no bias or offset adjustment procedure shown in the assembly manual. Each input board has an adjustable capacitor for the Excelinear circuit, and a mystery pot a few inches away.

What are the adjustment procedures for this amp?

Last edited:

Thats actaully pretty good.

With no DC offset adjustment ability on the XL280 or XL600. That amount of DC offset is really actually pretty good, for that amp. My XL-600 was over 600mv .after. relay latched.

My issue with 280/600 is that the front end power supply approach IS WRETCHED, a complete after thought, an embarrassment. As a shared L/R supply for low level signals.

I went back to standard DH-220 type power supply on my 280 and 600 amps... actually the single Musical Concepts PS200/PS500 boards with Mundorfs = KILLS stock factory ("dual power feed") implementation. GOOD MOVE!!!

With no DC offset adjustment ability on the XL280 or XL600. That amount of DC offset is really actually pretty good, for that amp. My XL-600 was over 600mv .after. relay latched.

My issue with 280/600 is that the front end power supply approach IS WRETCHED, a complete after thought, an embarrassment. As a shared L/R supply for low level signals.

I went back to standard DH-220 type power supply on my 280 and 600 amps... actually the single Musical Concepts PS200/PS500 boards with Mundorfs = KILLS stock factory ("dual power feed") implementation. GOOD MOVE!!!

Attachments

I'm just surprised you had an XL-280 with those precious matched JFETs on the front end and replaced it with Musical Concepts board?

A dead Hafler XL-280. Two exploded 470uF caps hidden away in the power supply board. A complete repair using a Musical Concepts PS-200M power supply board...

I'm just surprised you had an XL-280 with those precious matched JFETs on the front end and replaced it with Musical Concepts board?

I edited my original post to say "completed" instead of "complete". Amazing how much damage forgetting to put one letter on the end of a word can do!

As much as I respect John's PCB updates, both of my driver boards are working and probably have many years left in them, so they're still in service.

With no DC offset adjustment ability on the XL280 or XL600. That amount of DC offset is really actually pretty good, for that amp. My XL-600 was over 600mv .after. relay latched.

My issue with 280/600 is that the front end power supply approach IS WRETCHED, a complete after thought, an embarrassment. As a shared L/R supply for low level signals.

I went back to standard DH-220 type power supply on my 280 and 600 amps... actually the single Musical Concepts PS200/PS500 boards with Mundorfs = KILLS stock factory ("dual power feed") implementation. GOOD MOVE!!!

It is a weird hybrid in stock form. I would have at least reversed the order and done discrete rectifiers for each low side and then run a single rectifier module for the output stage. Better would be a 2nd transformer and dual rectifiers for the small side. Full Ozark Mod would be a 4 quadrant power supply with 4 toroids and bridges, right?

I'm going to do my sound tests right now and hopefully button this amp up and be done with it. So many other projects here.

"looks good on paper", utterly fails in production.

I agree reverse the order (if there were enough room in the chassis) to implement it, as separate front and combined output stage.

The entire "separate power supply" for the front end is (ideal? but) not required. As implemented by by Hafler, many steps backward...

Many would benefit (with stock PC40 or PC19s) by using high quality and larger [driver stage] storage with a good film bypass. The stock 100mfd cap IS ANEMIC, and the source(s) of limitations and possible need to "manage the P/S design better" to never clip the driver stages. Not that they could not design a good product(s) the difficulty is designing products with strict focus on price points... power supply (or supplies) always suffer.

Sad that many people with these stock boards are missing out, have no idea...

how lossy these boards are... will typically argue otherwise,

at no loss to me. They are "good enough" for most.

I have built and (thoroughly) tested this...........

please believe what you will.

It is a weird hybrid in stock form. I would have at least reversed the order and done discrete rectifiers for each low side and then run a single rectifier module for the output stage.

Better would be a 2nd transformer and dual rectifiers for the small side. Full Ozark Mod would be a 4 quadrant power supply with 4 toroids and bridges, right?

I agree reverse the order (if there were enough room in the chassis) to implement it, as separate front and combined output stage.

The entire "separate power supply" for the front end is (ideal? but) not required. As implemented by by Hafler, many steps backward...

Many would benefit (with stock PC40 or PC19s) by using high quality and larger [driver stage] storage with a good film bypass. The stock 100mfd cap IS ANEMIC, and the source(s) of limitations and possible need to "manage the P/S design better" to never clip the driver stages. Not that they could not design a good product(s) the difficulty is designing products with strict focus on price points... power supply (or supplies) always suffer.

Sad that many people with these stock boards are missing out, have no idea...

how lossy these boards are... will typically argue otherwise,

at no loss to me. They are "good enough" for most.

I have built and (thoroughly) tested this...........

please believe what you will.

Attachments

I agree reverse the order (if there were enough room in the chassis) to implement it, as separate front and combined output stage.

Theres a way to do it, I think.

I kept using the 25A rectifier modules and sent their outputs to the +/- inputs on John's board that would have been populated by his chosen IXYS. If I had gone with the HyperFreds, I could have jumped a wire off an unused AC eyelet on the PS200M and back out to a separate bridge module. I bet you could even do a pair for dual mono input side power. That should work, right?

I really would like you to post up some details of your input board mods. I think these boards are begging for film.

(more of) optimizing the parts

Thanks man!

Background - some context

I usually try to build and/or modify in groups of 3. Successively "leap-frogging", each step, each amp, then sum the collective changes of the 3 slightly different builds into the 1 final build... they start as a baseline, all built the same, all sound essentially the same or close to one another, it is easy to navigate meaningful changes / improvements.

I was not really trying to modify (the base circuit) an other wise good [for its day] front end design, but to work towards greater neutrality, that which I know can be possible. I *did not* change the values on the film caps. And (now) use the larger 330uf/100v cap in the driver stage, it will fit;

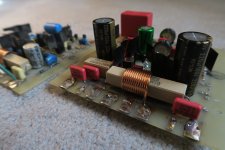

I was trying to "standardize" the stock Hafler PC19 (as shown) replace all electrolytics, passive parts, use silver micas below 1000 pf (get rid of cheap parts) I do like the Wimas *a lot* in scale of economy, transparency, consistency = I can / do stock every value and lead spacing for clean build practices.

The MUSE BP cap in the feedback loop, essentially stays the same value. 470uf, slightly tighter bass, 1,000uf slightly deeper bass (of course system dependent) I tend toward 470s, but like both.

**The image (as an off shoot / tangent) Before Musical Concepts PA7 entered the equation (I owned / was using 4 sets of PA4) I was beta matching front end transistors for the PC19 boards ~ I have not give up completely ~ yet. I would have rebuilt the PC-40(s) from the 600 and 280. But they have too many obstacles / for me, problems... time is much better spent/server elsewhere.

~ I want to emphasize this ~ I [usually] am not trying to redesign an already good design (or I would not have owned it)... as much as optimize it and get beyond many budget driven limits of the designs, while prolonging its useful life.

I like what you did there. When you swapped out the blueberries for the Wima films did you stay with stock values? How about the single BP?

Thanks man!

Background - some context

I usually try to build and/or modify in groups of 3. Successively "leap-frogging", each step, each amp, then sum the collective changes of the 3 slightly different builds into the 1 final build... they start as a baseline, all built the same, all sound essentially the same or close to one another, it is easy to navigate meaningful changes / improvements.

I was not really trying to modify (the base circuit) an other wise good [for its day] front end design, but to work towards greater neutrality, that which I know can be possible. I *did not* change the values on the film caps. And (now) use the larger 330uf/100v cap in the driver stage, it will fit;

I was trying to "standardize" the stock Hafler PC19 (as shown) replace all electrolytics, passive parts, use silver micas below 1000 pf (get rid of cheap parts) I do like the Wimas *a lot* in scale of economy, transparency, consistency = I can / do stock every value and lead spacing for clean build practices.

The MUSE BP cap in the feedback loop, essentially stays the same value. 470uf, slightly tighter bass, 1,000uf slightly deeper bass (of course system dependent) I tend toward 470s, but like both.

**The image (as an off shoot / tangent) Before Musical Concepts PA7 entered the equation (I owned / was using 4 sets of PA4) I was beta matching front end transistors for the PC19 boards ~ I have not give up completely ~ yet. I would have rebuilt the PC-40(s) from the 600 and 280. But they have too many obstacles / for me, problems... time is much better spent/server elsewhere.

~ I want to emphasize this ~ I [usually] am not trying to redesign an already good design (or I would not have owned it)... as much as optimize it and get beyond many budget driven limits of the designs, while prolonging its useful life.

Attachments

no DC offset adjustments

The ways various Hafler boards were built, were maddening to me.

No DC offset adjustment on PC6 or PC10 (numbers escape me)

for the all Hafler DH200s and early production DH500

And at the conclusion of this line up the XL-280 and XL600

goofy nature, with no real ways to resolve.

When you factor "magical FETS", that are no longer available

another stab to the longevity some great vintage gear.

I will not touch 5000 series Adcom or late vintage

Hafler Trans Nova, FET laden gear, due to this

long term uncertainty with too many FETS.

I am prepared to do some of the "front end work"

device matching = but *unable to move forward.

*unwilling, I have "given up" on them.

**Sorry not trying to be a thread hog,

I stirred up the topic, had to flesh it out...

The ways various Hafler boards were built, were maddening to me.

No DC offset adjustment on PC6 or PC10 (numbers escape me)

for the all Hafler DH200s and early production DH500

And at the conclusion of this line up the XL-280 and XL600

goofy nature, with no real ways to resolve.

When you factor "magical FETS", that are no longer available

another stab to the longevity some great vintage gear.

I will not touch 5000 series Adcom or late vintage

Hafler Trans Nova, FET laden gear, due to this

long term uncertainty with too many FETS.

I am prepared to do some of the "front end work"

device matching = but *unable to move forward.

*unwilling, I have "given up" on them.

**Sorry not trying to be a thread hog,

I stirred up the topic, had to flesh it out...

The ways various Hafler boards were built, were maddening to me

(....)

**Sorry not trying to be a thread hog,

I stirred up the topic, had to flesh it out...

Keep hogging, because this is great info!

Do you think Hafler might have left out the offset adjustment because it would have conflicted with the XL circuit?

And (now) use the larger 330uf/100v cap in the driver stage, it will fit;

Are you talking about the PC19 or the PC40 for that one? I saw you had the 220uF/100V in your pictures for the PC19.

As far as the BP, if the 1000uF means getting deeper bass, thats what I'll stick with. I noticed the parts list calls that cap a 6.3v but both PC40 in my amp have the 10V part instead. I used the 6.3v caps I had on hand, I doubt that will affect anything since the circuit is designed with that value.

common values in use

It applies to "to the nature of" and base design of their circuit. 6.3, 10, 16 will all work. ~ BUT ~ use the very best part possible. Nichicon MUSE is hard to beat and this cap will influence the overall transparency (nature) of the amp.

(at the time) I used the 220uf, a 15mm cap, already tight... by finessing surrounding smaller parts during replacement... the 330uf fit, by carefully repositioning the driver stage heatsink(s) on PC19 boards, as shown. There is plenty of room in the PC40, I just looked at it. The 330uf/100v MUSE is impossible to beat, and not separate supply is required.

Are you talking about the PC19 or the PC40 for that one? I saw you had the 220uF/100V in your pictures for the PC19.

As far as the BP, if the 1000uF means getting deeper bass, thats what I'll stick with. I noticed the parts list calls that cap a 6.3v but both PC40 in my amp have the 10V part instead. I used the 6.3v caps I had on hand, I doubt that will affect anything since the circuit is designed with that value.

It applies to "to the nature of" and base design of their circuit. 6.3, 10, 16 will all work. ~ BUT ~ use the very best part possible. Nichicon MUSE is hard to beat and this cap will influence the overall transparency (nature) of the amp.

(at the time) I used the 220uf, a 15mm cap, already tight... by finessing surrounding smaller parts during replacement... the 330uf fit, by carefully repositioning the driver stage heatsink(s) on PC19 boards, as shown. There is plenty of room in the PC40, I just looked at it. The 330uf/100v MUSE is impossible to beat, and not separate supply is required.

all this talk got me thinking

I was a busy ~ nearly dizzy ~ boy on Sunday.

*I will post further elsewhere on this.

thread jacking is not cool.

I found inspiration, while swapping parts.

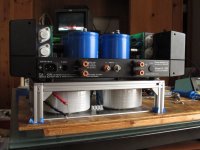

Power modules on heatsinks. Toroids, caps

cap banks. When this hits me.

Someone mentioned something here... TYTY

"Franken XL280" with my version of

A ROBUST POWER SUPPLY

There simply was not enough room

to do what I wanted... DH500 on a

200 series frame / body.

As SILLY as this may look

I am building it.

I was a busy ~ nearly dizzy ~ boy on Sunday.

*I will post further elsewhere on this.

thread jacking is not cool.

I found inspiration, while swapping parts.

Power modules on heatsinks. Toroids, caps

cap banks. When this hits me.

Someone mentioned something here... TYTY

"Franken XL280" with my version of

A ROBUST POWER SUPPLY

There simply was not enough room

to do what I wanted... DH500 on a

200 series frame / body.

As SILLY as this may look

I am building it.

Attachments

It applies to "to the nature of" and base design of their circuit. 6.3, 10, 16 will all work. ~ BUT ~ use the very best part possible. Nichicon MUSE is hard to beat and this cap will influence the overall transparency (nature) of the amp.

(at the time) I used the 220uf, a 15mm cap, already tight... by finessing surrounding smaller parts during replacement... the 330uf fit, by carefully repositioning the driver stage heatsink(s) on PC19 boards, as shown. There is plenty of room in the PC40, I just looked at it. The 330uf/100v MUSE is impossible to beat, and not separate supply is required.

Where I can find the right values and the surrounding parts will allow it, MUSE is my go-to brand.

- Home

- Amplifiers

- Solid State

- How do I adjust DC offset and bias on my Hafler XL-280