I use torque screwdriver by Sturtevant Richmont. It's a 29 piece set from McMaster-Carr. It's a bit pricey, $305, but it gets used a lot as it's the only way to do the job correctly. The driver may be available separately.

Craig

Nah, it's not the "only way", at least for me.

Having the experience to use a screwdriver properly for the job is worth tons more than $305.

+1

"non inductive" is hard to do in a wire-wound resistor format but the cheap, cement box resistors like KOA BPR and similar, use a single, short Z-folded alloy strip resistance element that has as low inductance in a practical 5W resistor as you will need.

This resistor type has been around in single and dual format for as long as I can remember in Japanese amplifiers. Now they are Chinese made but why go looking for grossly over-priced, exotic parts that likely are inferior anyway? Are audiophile parts choices based on some kind of "mine were more expensive so they are better" competition? Or is it not like all high-end audio marketing tricks - i.e. creating doubts and mystery about even straightforward physics in consumers' minds?

https://www.koaspeer.com/catimages/Products/BPR/BPR.pdf

"non inductive" is hard to do in a wire-wound resistor format but the cheap, cement box resistors like KOA BPR and similar, use a single, short Z-folded alloy strip resistance element that has as low inductance in a practical 5W resistor as you will need.

This resistor type has been around in single and dual format for as long as I can remember in Japanese amplifiers. Now they are Chinese made but why go looking for grossly over-priced, exotic parts that likely are inferior anyway? Are audiophile parts choices based on some kind of "mine were more expensive so they are better" competition? Or is it not like all high-end audio marketing tricks - i.e. creating doubts and mystery about even straightforward physics in consumers' minds?

https://www.koaspeer.com/catimages/Products/BPR/BPR.pdf

The only thing about using "dummy loads" as test loads is.......

They're NOT a speaker, they're purely resistive.

Speakers, being resistive, also have inductance, varying hysteresis, and feedback to the amp stuff going on.

You've got a voice coil bouncing back and forth within a strong magnetic field.

So testing an amp using dummy loads is kind of "not real world" accurate.

They're NOT a speaker, they're purely resistive.

Speakers, being resistive, also have inductance, varying hysteresis, and feedback to the amp stuff going on.

You've got a voice coil bouncing back and forth within a strong magnetic field.

So testing an amp using dummy loads is kind of "not real world" accurate.

I see. And what would you propose alternatively? Testing each amp with all speakers of the world under all conditions?

Sometimes, you just need to be reasonable, sensible, and compromise.

Various electrolytic capcitors in the signal path do affect sound. How much of a difference depends on many factors. Bias, voltage swing, loading, etc all will affect the distortion characteristics. There are a few studies done on this subject and the rough conclusion is the best type of electrolytic to use for audio coupling are non polar types. I have done my own testing and evaluation and the results are in line with the findings others have made. More often than not I found that a non polar electrolytic in a coupling application can sound as good as or even better than some high end film caps. I always prefer non inductive leads when I can find them. The nichicon muse series are one of the best non polar audio coupling caps available IMO. Distortion measurments back this up as well.

I've "upgraded" many sets of emmiter resistors in quite a few amps before with various results. To my ears, the mills/vishay wire wounds are some of the best available. I like the Koa metox resistors too, but they need to be heat cycled a few times under load to weed out the ones that drift further away from target spec. Metox resistors aren't as tolerant to high temp transients as wire wounds and usually have a higher temp coefficient. For these reasons, I only use them if I can get ahold of and fit higher wattage values than originally called for. You always want non-magnetic leads whenever possible.

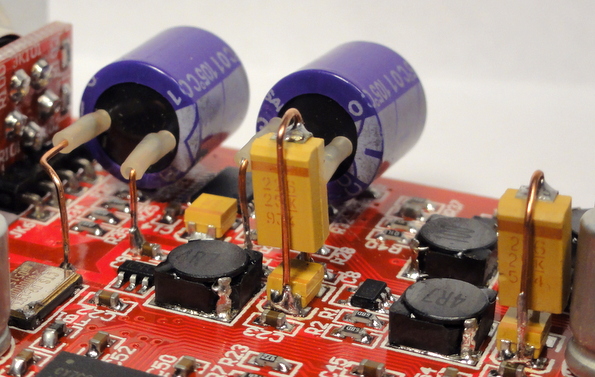

With film caps, I always avoid mylar like the plague. Its not a good dielectric material. Most polypropylene, teflon and PPS are good in my book, as long as the leads are non-magnetic. The problem with larger film caps is inductance and sometimes its better to use stacked plate versions whenever available. Sometimes you have to use non polar electrolytics. Like many other audio-phools out there, I retrofit a lot of equipment with better coupling caps, sometimes making a noticeable difference and other times going backwards in sound. Most of the time though, replacing cheaper non polar electrolyotics with nichicon muse does wonders. Swapping polar electrolytics are hit and miss, depending on location but in power supply applications the Panasonic EB series work well, especially in high temp situations like next to heat sinks and locations with heat build up and lack of ventilation. They're cheap, reliable and are readily available. United chemicon KZ is very good in switching supplies when you really need low esr, but don't use them in linear power supplies. Stay away from the panasonic FC series.... I've had a few issues with these and they do weird things to the audio.

I've "upgraded" many sets of emmiter resistors in quite a few amps before with various results. To my ears, the mills/vishay wire wounds are some of the best available. I like the Koa metox resistors too, but they need to be heat cycled a few times under load to weed out the ones that drift further away from target spec. Metox resistors aren't as tolerant to high temp transients as wire wounds and usually have a higher temp coefficient. For these reasons, I only use them if I can get ahold of and fit higher wattage values than originally called for. You always want non-magnetic leads whenever possible.

With film caps, I always avoid mylar like the plague. Its not a good dielectric material. Most polypropylene, teflon and PPS are good in my book, as long as the leads are non-magnetic. The problem with larger film caps is inductance and sometimes its better to use stacked plate versions whenever available. Sometimes you have to use non polar electrolytics. Like many other audio-phools out there, I retrofit a lot of equipment with better coupling caps, sometimes making a noticeable difference and other times going backwards in sound. Most of the time though, replacing cheaper non polar electrolyotics with nichicon muse does wonders. Swapping polar electrolytics are hit and miss, depending on location but in power supply applications the Panasonic EB series work well, especially in high temp situations like next to heat sinks and locations with heat build up and lack of ventilation. They're cheap, reliable and are readily available. United chemicon KZ is very good in switching supplies when you really need low esr, but don't use them in linear power supplies. Stay away from the panasonic FC series.... I've had a few issues with these and they do weird things to the audio.

Sometimes, you just need to be reasonable, sensible, and compromise.

Testing is by its nature, contrived. We are looking for a repeatable reference that doesn’t add distortion to compare amps. The LTSpice sims used to design the amp also uses a pure resistive load.

All speakers will be orders of magnitude higher in intrinsic distortion than an amp. Yet the differences in lower distortion harmonic profiles from the amp are audible.

We are looking for a repeatable reference that doesn’t add distortion to compare amps. The LTSpice sims used to design the amp also uses a pure resistive load.

You can make a low distortion pseudo-inductive load with a resistor and an amp.

If your amp is stereo, connect your low distortion resistor between both outputs. Then, with your soundcard, have one channel output the test frequency, and the other channel output the same frequency, with a phase shift. So you get any phase shift you want between voltage and current.

Note standard THD measurements are mostly useless. But if you add a DC output current offset with a current source (or another amp that outputs DC and a resistor), step the current from say -2A to +2A, and for each offset current, measure gain and THD on a low level AC current, say 10kHz 10 mA. Then this tells an interesting story.

I have done this with a soundcard, one channel to an amp that outputs +/-16V 20Hz sinewave, thru a 8R resistor, into the output of the amp under test, the other channel outputs 48kHz sinewave at low amplitude, to another amp, into the output of the amp under test with a high value resistor so it does about 10mApp. Record output voltage of amp under test, detect amplitude of 48kHz signal, plot versus amplitude of 20Hz current. This measures output impedance of amp at 48kHz versus "DC" output current. Wingspan diagram of crossover appears on screen, with self heating, bias drift, etc. Easy. Artifacts have nowhere to hide.

Last edited:

The problems amplifiers usually have is how they respond to complex difficult loads like a big multi-way speaker, not so much as just a voltage amplifier driving an easy resistive load.

Dummy loads are really only good for testing theoretical rms power output and verifying basic voltage gain / power supply ripple of an amplifier.

I was working on a Tandberg amp a while back that I completely rebuilt with exact spec parts. The amp would test perfect on the dummy load, but the clip lights would briefly flash occasionally playing at low levels through speakers. I found out there was intermittent oscillation in the output pre-drivers due to the new output transistors from a different supplier (same part number) being higher bandwidth than spec. I increased the value of the small base-emitter compensation caps and the problem was solved. The dummy load didn't show the problem even at close to clipping levels into 4 ohms.

Dummy loads are really only good for testing theoretical rms power output and verifying basic voltage gain / power supply ripple of an amplifier.

I was working on a Tandberg amp a while back that I completely rebuilt with exact spec parts. The amp would test perfect on the dummy load, but the clip lights would briefly flash occasionally playing at low levels through speakers. I found out there was intermittent oscillation in the output pre-drivers due to the new output transistors from a different supplier (same part number) being higher bandwidth than spec. I increased the value of the small base-emitter compensation caps and the problem was solved. The dummy load didn't show the problem even at close to clipping levels into 4 ohms.

I was working on a Tandberg amp a while back that I completely rebuilt with exact spec parts. The amp would test perfect on the dummy load, but the clip lights would briefly flash occasionally playing at low levels through speakers. I found out there was intermittent oscillation in the output pre-drivers due to the new output transistors from a different supplier (same part number) being higher bandwidth than spec. I increased the value of the small base-emitter compensation caps and the problem was solved. The dummy load didn't show the problem even at close to clipping levels into 4 ohms.

That's usually the case when replacing/upgrading certain output transistors, and now you learned something new!

Yes, I was familiar with this issue from fixing up a lot of Flame Linear 700 amps. Those things are so crude in design that anything you do different to the output stage will require tweaking to get somewhat stable. Same holds true for Haflers and Dynacos, but those are actually more mod friendly.

Testing each amp with all speakers of the world under all conditions?

Something like this, for example.

Real-Life Measurements | Stereophile.com

Thank you all for replying my post

However I have made a little research and I have got the schematic of the big brother the 33

The 33 and the 33H share the same topology and the same architecture of design with minor changes.

As for the emmiter resistors the 33 uses non inductive resistors

So I have decided to give it a shot which is not reasonable to me.

Is there any one here that changes the emmiter resistors and it was sound changes?

If you do please let me know what to expect...

Beside of that all those resistors connected via second group of resistors (4 in parallel 0.33ohm each ) which are inductive as well and I am willing to change also those for non inductive

However I have made a little research and I have got the schematic of the big brother the 33

The 33 and the 33H share the same topology and the same architecture of design with minor changes.

As for the emmiter resistors the 33 uses non inductive resistors

So I have decided to give it a shot which is not reasonable to me.

Is there any one here that changes the emmiter resistors and it was sound changes?

If you do please let me know what to expect...

Beside of that all those resistors connected via second group of resistors (4 in parallel 0.33ohm each ) which are inductive as well and I am willing to change also those for non inductive

Hi Nehoray,

Okay, I wouldn't but go right ahead.

If there is a sound change, it is oscillating. Otherwise it will not change the sound. Remember, these are inside the feedback loop.

Dummy loads are used as a standard. You can argue this point from every angle and get no where. Yes, I also run amplifiers on real speakers as well. But if you make measurements (and if you don't, you have no business working on an amplifier), it is the only way you can compare the results to published specs.

The accepted industry standard dummy load is the Dale 8R 1% 250W non-inductive resistor. Period. That's it, there is no other acceptable dummy load to use if you intend to do this in a professional manner. I bought 3 pairs of these, and milled heat sinks flat so I could mount them properly. So, I put my money where my mouth is. This was a requirement for me to operate a warranty shop for many brands of good equipment. I didn't have a choice if I wanted to perform warranty work, or any work recognized as valid.

-Chris

Okay, I wouldn't but go right ahead.

If there is a sound change, it is oscillating. Otherwise it will not change the sound. Remember, these are inside the feedback loop.

Dummy loads are used as a standard. You can argue this point from every angle and get no where. Yes, I also run amplifiers on real speakers as well. But if you make measurements (and if you don't, you have no business working on an amplifier), it is the only way you can compare the results to published specs.

The accepted industry standard dummy load is the Dale 8R 1% 250W non-inductive resistor. Period. That's it, there is no other acceptable dummy load to use if you intend to do this in a professional manner. I bought 3 pairs of these, and milled heat sinks flat so I could mount them properly. So, I put my money where my mouth is. This was a requirement for me to operate a warranty shop for many brands of good equipment. I didn't have a choice if I wanted to perform warranty work, or any work recognized as valid.

-Chris

Hi Chris,

Can you point us to the industry standard that states the type of resistor to be used for audio amp distortion testing? Is it a standard published by IEEE, IEC, AES, etc? Usually, a neutral party standards organization will not specify a particular brand, but they will specify the performance requirements or construction method.

A quick search of Dale 250w non inductive 1% turns up the classic wire wound construction. Is this the part? NH2508R000FJ01 $170ea.

NH2508R000FJ01 Vishay / Dale | Mouser

It is wirewound, and it’s interesting how to achieve non-inductive behavior when windings are what is used to make inductors.

Edit: data sheet says Ayrton-Perry windings are used to reduce parasitic inductance. Cool. Requires 4x the length of wire.

Can you point us to the industry standard that states the type of resistor to be used for audio amp distortion testing? Is it a standard published by IEEE, IEC, AES, etc? Usually, a neutral party standards organization will not specify a particular brand, but they will specify the performance requirements or construction method.

A quick search of Dale 250w non inductive 1% turns up the classic wire wound construction. Is this the part? NH2508R000FJ01 $170ea.

NH2508R000FJ01 Vishay / Dale | Mouser

It is wirewound, and it’s interesting how to achieve non-inductive behavior when windings are what is used to make inductors.

Edit: data sheet says Ayrton-Perry windings are used to reduce parasitic inductance. Cool. Requires 4x the length of wire.

Last edited:

- Home

- Amplifiers

- Solid State

- Low noise Emmiter resistors