Great work guys. The Nichicon UBY ecaps are great for this app, fully insulated, 135C, excellent specs.

I see one correction its "fish paper" I remember Motorola using it years ago in the two-way radio factory. Some spelling too

I am sure Bob C is as am I, elated with your builds, pics, docs, tests, reviews.

Cheers

Rick

I see one correction its "fish paper" I remember Motorola using it years ago in the two-way radio factory. Some spelling too

I am sure Bob C is as am I, elated with your builds, pics, docs, tests, reviews.

Cheers

Rick

# HaflerDh500Fan

You post that message exactly when I want to hit the "Buy" button at the Mouser bom materials....That save me to change a few things based on your guidance. Great.

Can I ask if you tried to experiment with input capacitor ( to be able to stay safe if you use a tube preamp ) ? From my experience I know that can be some trouble because of DC at the output of such preamps....

What speakers did you have for DH500?

THX.

You post that message exactly when I want to hit the "Buy" button at the Mouser bom materials....That save me to change a few things based on your guidance. Great.

Can I ask if you tried to experiment with input capacitor ( to be able to stay safe if you use a tube preamp ) ? From my experience I know that can be some trouble because of DC at the output of such preamps....

What speakers did you have for DH500?

THX.

Attachments

@Felixx

Glad the info is helpful. I didn’t experiment using different input coupling caps. If you feel you need them, I would first try the ones that Rick specified in the BOM. If you want to try different ones, some likely candidates are large and would have to be located either on the side of the board or off the board. I’ve used Mundorf Supreme 2.2 uf as coupling caps in my phono preamp with good success. My understanding Jantzen caps are also good. Each person has their own preference. However, I think everyone would agree that a straight wire (no cap) is the best sounding. I believe the DC servo control on the DH220C board coupled with the DC offset protection with the DH500 output relay is adequate protection so the coupling cap is not required. You asked about my speakers…I have a vintage pair of Vandersteen 2C's although I’ll probably be getting some Magnepan 0.7 speakers soon. The high current Hafler DH500 should drive the Maggies nicely.

There was a question earlier about the value for R1/R2 on the DH220C boards. Per my earlier post that listed the various changes, R1/R2 were increased from 1,500 ohm for the DH220 to 3,300 ohm for the DH500 application (keeping the same 3 watt rating). Looking back at my notes and correspondences, Bob suggested increasing the resistance proportional to the increase in supply voltage which would give roughly 2,200 ohm. However, Bob did mention that the base design is running a bit more current thru the Zener diodes than necessary and that in the DH500 the resistors will run slightly hotter with the higher voltage across them. Based on this input and being the first-time application in the DH500, Rick and I agreed on the 3,300 ohm value. These resistors do run hot and give off a lot of heat. That’s why they are set 1 inch off the board. However, I did make a change to R1/R2 recently based on some experience with two other existing resistors in the DH500 that run hot. These are R409 and R410 which are part of the heat sink fan circuit. These were sand filled wirewound resistors. I experimented and changed them to wirewound “thru hole” type. They seem to dissipate the heat better with the larger surface area with the thru hole annulus. So, I changed R1/R2 to the same type. Based on availability, I selected 3,000 ohm/5.25 watt rating (Mouser part no. 588-B5J3K0E). So far, I’m pleased the way they dissipate the heat better. Though they are pricey @ $5.45 each.

Glad the info is helpful. I didn’t experiment using different input coupling caps. If you feel you need them, I would first try the ones that Rick specified in the BOM. If you want to try different ones, some likely candidates are large and would have to be located either on the side of the board or off the board. I’ve used Mundorf Supreme 2.2 uf as coupling caps in my phono preamp with good success. My understanding Jantzen caps are also good. Each person has their own preference. However, I think everyone would agree that a straight wire (no cap) is the best sounding. I believe the DC servo control on the DH220C board coupled with the DC offset protection with the DH500 output relay is adequate protection so the coupling cap is not required. You asked about my speakers…I have a vintage pair of Vandersteen 2C's although I’ll probably be getting some Magnepan 0.7 speakers soon. The high current Hafler DH500 should drive the Maggies nicely.

There was a question earlier about the value for R1/R2 on the DH220C boards. Per my earlier post that listed the various changes, R1/R2 were increased from 1,500 ohm for the DH220 to 3,300 ohm for the DH500 application (keeping the same 3 watt rating). Looking back at my notes and correspondences, Bob suggested increasing the resistance proportional to the increase in supply voltage which would give roughly 2,200 ohm. However, Bob did mention that the base design is running a bit more current thru the Zener diodes than necessary and that in the DH500 the resistors will run slightly hotter with the higher voltage across them. Based on this input and being the first-time application in the DH500, Rick and I agreed on the 3,300 ohm value. These resistors do run hot and give off a lot of heat. That’s why they are set 1 inch off the board. However, I did make a change to R1/R2 recently based on some experience with two other existing resistors in the DH500 that run hot. These are R409 and R410 which are part of the heat sink fan circuit. These were sand filled wirewound resistors. I experimented and changed them to wirewound “thru hole” type. They seem to dissipate the heat better with the larger surface area with the thru hole annulus. So, I changed R1/R2 to the same type. Based on availability, I selected 3,000 ohm/5.25 watt rating (Mouser part no. 588-B5J3K0E). So far, I’m pleased the way they dissipate the heat better. Though they are pricey @ $5.45 each.

In the DH-220C(AFE) BOM, at the end, it lists the PP film caps that are available at Mouser which can be optionally used. Our first DH-220C beta tester did the input coupling cap comparisons and ended up saying the original choices were not so bad after all.

If you guys can hear the difference in a coupling cap, I'll give you a bow since I can not do so. Speakers are easy caps are not for me for another time

since I can not do so. Speakers are easy caps are not for me for another time

If you look at the Hafler DH500 protection ckt they use two 500mW zeners in parallel. You can also use a 1W zener (1N47??) if we are concerned about zener long term reliability. Lots of possibilities.

I can see a few things going on, that I would like to comment on.

1) We have the Hafler DH-500C/P500C and we have using the DH-220C design and its variants

2) Do you folks think the two should be in the same thread?

3) I think they should split because DH-220C design variants is off topic of the DH-500C+ as "HaflerDh500Fan" has built his unit. But it does not really matter to me, others may complain, we are kinda captive in our discussions.

I see that folks are wanting to build this DH-220C design project in other than Hafler chassis which is great imo. But it is not 100% setup for this for the best mechanics.

It is possible to design new OPS's which the mirror along the long edge so that AFE and OPS face each other and can mount on the same HS surface. With no or minimal wires crossing. DH-220CR(OPS) was designed for this but it looks like the P230CR(OPS) and DH-500CR(OPS) need to be done too. Add them to my to do list, if there is enough interest.

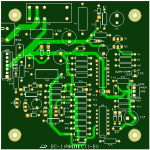

We have been designing some other pcb's as well, PS & Protection, to go along with our BC-1 design as shown in Bob's latest book. We are working them up in a 3U Modu shop chassis presently. They could be of use for others to use. If we split the thread they can be discussed at length.

So it would be good to hear your opinions.

Thanks

Rick

If you guys can hear the difference in a coupling cap, I'll give you a bow

If you look at the Hafler DH500 protection ckt they use two 500mW zeners in parallel. You can also use a 1W zener (1N47??) if we are concerned about zener long term reliability. Lots of possibilities.

I can see a few things going on, that I would like to comment on.

1) We have the Hafler DH-500C/P500C and we have using the DH-220C design and its variants

2) Do you folks think the two should be in the same thread?

3) I think they should split because DH-220C design variants is off topic of the DH-500C+ as "HaflerDh500Fan" has built his unit. But it does not really matter to me, others may complain, we are kinda captive in our discussions.

I see that folks are wanting to build this DH-220C design project in other than Hafler chassis which is great imo. But it is not 100% setup for this for the best mechanics.

It is possible to design new OPS's which the mirror along the long edge so that AFE and OPS face each other and can mount on the same HS surface. With no or minimal wires crossing. DH-220CR(OPS) was designed for this but it looks like the P230CR(OPS) and DH-500CR(OPS) need to be done too. Add them to my to do list, if there is enough interest.

We have been designing some other pcb's as well, PS & Protection, to go along with our BC-1 design as shown in Bob's latest book. We are working them up in a 3U Modu shop chassis presently. They could be of use for others to use. If we split the thread they can be discussed at length.

So it would be good to hear your opinions.

Thanks

Rick

Last edited:

Hi Dan,

Do you have Bob's latest edition? It has the BC-1 PS and protection ckts in chapter four.

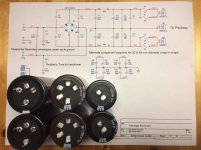

The goal is to make them for use in the Modu-shop chassis ( 10 cm Mounting hole spacings) but they are for general purpose use as well. I have a few pics I can share.

I am making use of the PS as a test supply.

Plan on doing another PS version, if this form factor works out for that chassis. Use some ST FERD diodes instead of the old 35A bridge. There are many possible options.

Do you have Bob's latest edition? It has the BC-1 PS and protection ckts in chapter four.

The goal is to make them for use in the Modu-shop chassis ( 10 cm Mounting hole spacings) but they are for general purpose use as well. I have a few pics I can share.

I am making use of the PS as a test supply.

Plan on doing another PS version, if this form factor works out for that chassis. Use some ST FERD diodes instead of the old 35A bridge. There are many possible options.

Attachments

Last edited:

I recently replaced the original DH500 speaker protection (mechanical reply switch plus PC9 board) with a Neurochrome Guardian 686 board. It accomplishes the same protection (guards against excessive DC voltage and any sharp voltage transients on power-up and power-down) without the need of a mechanical relay switch where the contact surfaces can deteriorate over time and impact performance. Instead it uses MOSFETs to do the switching. The board also gives you the option of mounting directly to the binding post terminals that are spaced 0.75” apart. I originally intended to do that but changed mid-course from binding posts to GR Research tube connectors so I mounted the Guardian 686 board just above the speaker outputs. The board uses the DC power supply and two diodes had to be changed on the board to handle the higher voltage supply in the DH500 (which Tom Christiansen pointed out). I believe it's the first time being used in the DH500 and works great.

DH500 build(s) - before and after

More room for improvement than for parts... Most people (too many) neglect much needed power supply improvement(s)... absolutely, the Achilles Heal of an otherwise very good amp. Sadly, people do not realize what they are missing.

A friend brought me these 2 bridged DH-500 amps, to repair and modify, both had been badly abused... I had never touched a single Hafler amp with blown outputs. These amps were used on sub-woofer stack with 2 ohm load. The prior owner had 10 amp slow blow fuses in all 4 B+ slots. I guess he got tired of replacing fuses, killing his amps...

I was 'half afraid' to plug them in to even test them... they were that scary. These were the worst Hafler(s) that I have seen in nearly 40 years of work with an amp we would sell to customers that seem to destroy every amp they bought. EG. in the days of switch boxes, with multiple (too many) speakers connected at once in multiple rooms.

I liked the sound of his amp SO MUCH, I am building the one on the bottom [now mine, rebuilt image 2] to be just like the one I built for him with Exicon dual die MOSFETS, I think that it **out preformed my Hafler XL600 (which I am now subsequently rebuilding) I did everything that I could think of to his, and it outperformed my own amps... I struggled unplugging and delivering his amp, with did AMAZING things on my Maggies, never heard them sound this good.

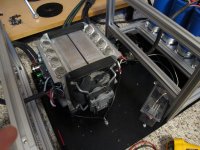

Image 2 and 3 are the 500 / 600 power modules connected to my MONDO CLC power supplies, to test different amp configurations and is the **basis for my comment and comparison. The 600 *not shown, is now nearly finished, still on the workbench...

The more that I [test] "throw at them", the greater the improvement(s). The beefier P/S benefits the 'super-charged' amp module ~ and ~ the "enhanced" amp module(s) render the P/S sound quality improvements and is capable of "handling" a massive and super stiff P/S, in ways a stock PC19 PCB could not.

Lastly, these reworked amps (as shown) have the small amp finesse and delicacy, with the big amp effortless ease, neutrality that gets out of the way of the music.

More room for improvement than for parts... Most people (too many) neglect much needed power supply improvement(s)... absolutely, the Achilles Heal of an otherwise very good amp. Sadly, people do not realize what they are missing.

A friend brought me these 2 bridged DH-500 amps, to repair and modify, both had been badly abused... I had never touched a single Hafler amp with blown outputs. These amps were used on sub-woofer stack with 2 ohm load. The prior owner had 10 amp slow blow fuses in all 4 B+ slots. I guess he got tired of replacing fuses, killing his amps...

I was 'half afraid' to plug them in to even test them... they were that scary. These were the worst Hafler(s) that I have seen in nearly 40 years of work with an amp we would sell to customers that seem to destroy every amp they bought. EG. in the days of switch boxes, with multiple (too many) speakers connected at once in multiple rooms.

I liked the sound of his amp SO MUCH, I am building the one on the bottom [now mine, rebuilt image 2] to be just like the one I built for him with Exicon dual die MOSFETS, I think that it **out preformed my Hafler XL600 (which I am now subsequently rebuilding) I did everything that I could think of to his, and it outperformed my own amps... I struggled unplugging and delivering his amp, with did AMAZING things on my Maggies, never heard them sound this good.

Image 2 and 3 are the 500 / 600 power modules connected to my MONDO CLC power supplies, to test different amp configurations and is the **basis for my comment and comparison. The 600 *not shown, is now nearly finished, still on the workbench...

The more that I [test] "throw at them", the greater the improvement(s). The beefier P/S benefits the 'super-charged' amp module ~ and ~ the "enhanced" amp module(s) render the P/S sound quality improvements and is capable of "handling" a massive and super stiff P/S, in ways a stock PC19 PCB could not.

Lastly, these reworked amps (as shown) have the small amp finesse and delicacy, with the big amp effortless ease, neutrality that gets out of the way of the music.

Attachments

Last edited:

- Home

- Amplifiers

- Solid State

- Hafler DH-500/P500 Mods