Agree wiper of potentiometer can lose contact with carbon track after some years.

All mil spec & high rel potentiometer factories have been re-developed as shopping malls or used car lots. What is on market now is IMHO fluff & glitter.

Most reliable way to set bias current permanently is:

1 set bias voltage with amp warmed up with potentiometer.

2 Measure potentiometer with power off, possibly removed from circuit.

3 replace potentiometer with a fixed resistor. The value may not be a standard one, and you may have to parallel or series 2 or 3 resistors to match the value.

All mil spec & high rel potentiometer factories have been re-developed as shopping malls or used car lots. What is on market now is IMHO fluff & glitter.

Most reliable way to set bias current permanently is:

1 set bias voltage with amp warmed up with potentiometer.

2 Measure potentiometer with power off, possibly removed from circuit.

3 replace potentiometer with a fixed resistor. The value may not be a standard one, and you may have to parallel or series 2 or 3 resistors to match the value.

Last edited:

I'm going to beg to differ with the comment that bias changes or drifts over time and ask by what mechanism that may occur?

Sure, passive parts and fixed value parts generally stay stable for long periods but on the other hand, the variable resistors / potentiometers that I've often seen controlling the bias do have a tendency (IME) to degrade and cause the bias point to shift. The contact between the wiper and the track can oxidise and the resistance change.

Passive parts are stable and the semiconductors unchanging in their characteristics year on year. The biggest problem many have checking the bias is in not being able to replicate the test conditions exactly.

The test conditions are generally well stated in the service manuals - switch on and warm up, set a particular voltage across a particular resistor or test point. Leave idle for half hour or so, repeat the measurement and process until stable at the defined operating voltage.

The assumption here is that the factory / last service tech performed the bias adjustment to spec, which is not known.

Agree wiper of potentiometer can lose contact with carbon track after some years.

All mil spec & high rel potentiometer factories have been re-developed as shopping malls or used car lots. What is on market now is IMHO fluff & glitter.

Most reliable way to set bias current permanently is:

1 set bias voltage with amp warmed up with potentiometer.

2 Measure potentiometer with power off, possibly removed from circuit.

3 replace potentiometer with a fixed resistor. The value may not be a standard one, and you may have to parallel or series 2 or 3 resistors to match the value.

This is the best solution for longevity IMO, although as stated, can end up with an inconvenient value of resistor.

hi guy

been reading this thread with interest, and i have a question re- removing potentiometer.

is there a particular type/brand of resistor that works better with audio circuits ??

cheers

gaz

Yes, will be good to know opinion of experienced guys.

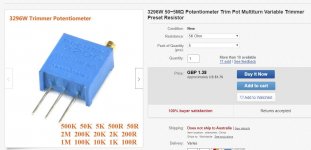

In between I am planning to replace all 5 mine potentiometers with ebay item 223501711370.

Well, they certainly are cheap!

But... they are cheap.......

You will do much better to replace them with decent, reliable parts such as a Vishay:

https://uk.farnell.com/w/c/passive-...ulti-turn&potentiometer-mounting=through-hole

Just remember that Ebay is often a clearing house for Chinese factory parts that didn't make the cut (poor quality, out of tolerance, copies etc).

As to fixed resistors, it depends on the power requirements and the application. I generally use the Metal Film CMF55 range for 600mW 1% general purpose. If it is higher power, I tend to use the PR02 and PR03 (2W and 3W) range. All of these are available through reputable sellers (Farnell / Element14, Mouser, RS Components, ARROW etc.).

For a bias resistor, I would use minimum tolerance of 1%.

But... they are cheap.......

You will do much better to replace them with decent, reliable parts such as a Vishay:

https://uk.farnell.com/w/c/passive-...ulti-turn&potentiometer-mounting=through-hole

Just remember that Ebay is often a clearing house for Chinese factory parts that didn't make the cut (poor quality, out of tolerance, copies etc).

As to fixed resistors, it depends on the power requirements and the application. I generally use the Metal Film CMF55 range for 600mW 1% general purpose. If it is higher power, I tend to use the PR02 and PR03 (2W and 3W) range. All of these are available through reputable sellers (Farnell / Element14, Mouser, RS Components, ARROW etc.).

For a bias resistor, I would use minimum tolerance of 1%.

Attachments

As the bias pot may end up at any value,it may not match any fixed value resistor sold. Measure the pot out of circuit, parallel or series connect any two or three stable value resistors until get the same value that your meter measured. I'm storing a 5 kg stock of fixed resistors, have most of the 10% stock values, do not intend to have every 1% value sold. I've found that 1% resistors slightly off value from 10% values are often a twentieth the price of 10% resistors in standard values. If they are under $.01 (I miss the cents symbol) I'll buy 100 to make it worth newark's while to bag them.For a bias resistor, I would use minimum tolerance of 1%.

I have demonstrated to my satisfaction that metal film resistors over 100 kohm are quieter than carbon comp. As reported on parts forum. I've gotten competent metal film resistors from vishay, dale, te connectivity, welwyn, multicomp(farnell house brand). All via newark(farnell) digikey, mouser, to make sure they are not counterfeit. I've received from mouser resistors only made in a country noted for counterfeiting, cheating or bribing the QA inspector, ignoring food safety laws. Carbon film resistors are reported to be quieter than carbon comp, have never bought any.

That ebay pot looks just like a bourns, but isn't. Laughable spelling.

Thickness of carbon track or number of expected movement cycles are not advertised specifications of pots. Neither is the type plating on the wiper. There are obviously some competent long life 50 mm slide 10 k pots being sold to mixer manufacturers. These last quite a while. The ability of an individual to buy a pot of similar expected life from any distributor cannot be demonstrated. I've replaced a worn out master volume pot in a Peavey PV8 mixer with a bourns pot. It has lasted 10 movements without trouble so far.

Last edited:

The company has a large catalogue and web page:

China Wirewound Resistor Factory, Wirewound Resistor Supplier

China 3296 Factory, 3296 Supplier

It would be wrong to write them off without evidence to the contrary.

China Wirewound Resistor Factory, Wirewound Resistor Supplier

China 3296 Factory, 3296 Supplier

It would be wrong to write them off without evidence to the contrary.

Thanks for replies, guys.

I am going to do some tuning of idle currents and ISC (as described in service manual).

Not sure if all original trim pots will function OK, so I bought set of replacements:

BOURNS - 3296Y-1-201LF - TRIMMER, 25 TURN 200R x2

BOURNS - 3296Y-1-503LF - TRIMMER, 25 TURN 50K x1

BOURNS - 3296Y-1-101LF - TRIMMER, 25 TURN 100R x2

In total I paid 17.5$ at local store.

I won't do the replacement by fixed resistors as I think I will need some more tuning in the future. Want to keep tuning as option.

I am going to do some tuning of idle currents and ISC (as described in service manual).

Not sure if all original trim pots will function OK, so I bought set of replacements:

BOURNS - 3296Y-1-201LF - TRIMMER, 25 TURN 200R x2

BOURNS - 3296Y-1-503LF - TRIMMER, 25 TURN 50K x1

BOURNS - 3296Y-1-101LF - TRIMMER, 25 TURN 100R x2

In total I paid 17.5$ at local store.

I won't do the replacement by fixed resistors as I think I will need some more tuning in the future. Want to keep tuning as option.

Hi, guys.

Thanks for all your comments.

Wanted to share my status here.

Values of 10mv I did not measure by myself, they were given to me by some rip off guy, who took money for "testing" abd "tuning" my amp when in fact he did not do/change anything. So, this 10mv value was a lie. I visit this guy again and took my money back.

I grew up to do measurements by myself and what I saw that actual values are 1.4mv on one channel and 1.8mv on another channel (instead of needed 3-3.5mv specified in service manual).

Right now I put both channels on 3.5mv (using same old garbage trim pots installed by NAD) and now my amp sounding so clean! No muddy bass now, everything sounds really good even on my dirt chip speakers. NAD drives them crazy Any way I am not very experienced in sound, but I can hear really significant improvement.

Any way I am not very experienced in sound, but I can hear really significant improvement.

One thing that I am worried now a bit is a heat. Amp started to produce more heat and I think of adding external fans (like PC silent Noctua fan with external 12v power supply).

Will check values in next 180 days to see if they drifted or not.

I still not installed new trim pots, but will do it in future.

Thanks for all your comments.

Wanted to share my status here.

Values of 10mv I did not measure by myself, they were given to me by some rip off guy, who took money for "testing" abd "tuning" my amp when in fact he did not do/change anything. So, this 10mv value was a lie. I visit this guy again and took my money back.

I grew up to do measurements by myself and what I saw that actual values are 1.4mv on one channel and 1.8mv on another channel (instead of needed 3-3.5mv specified in service manual).

Right now I put both channels on 3.5mv (using same old garbage trim pots installed by NAD) and now my amp sounding so clean! No muddy bass now, everything sounds really good even on my dirt chip speakers. NAD drives them crazy

One thing that I am worried now a bit is a heat. Amp started to produce more heat and I think of adding external fans (like PC silent Noctua fan with external 12v power supply).

Will check values in next 180 days to see if they drifted or not.

I still not installed new trim pots, but will do it in future.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Diagnose of my AMP, please