10th anniversary makeover

I completed my KSA-50 build in 2007. It took longer than I had planned and, combined with a job change and added daily commute time, I never put the final touch in the mono-blocs’ appearance. I decided they would get a makeover for their 10th anniversary, starting with a thorough cleaning of all the aluminum parts which still had Sharpie markings from the cutting and drilling steps. The makeover would also add long output boards to better use the length of the heat sinks, and front panels, which I never got to make back then.

After I had taken the units apart and cleaned up the aluminum panels, Troy posted this:

http://www.diyaudio.com/forums/solid-state/31077-krell-ksa-50-pcb-355.html#post5195136

I decided to take pictures of the makeover and post them, so he can hopefully enjoy them.

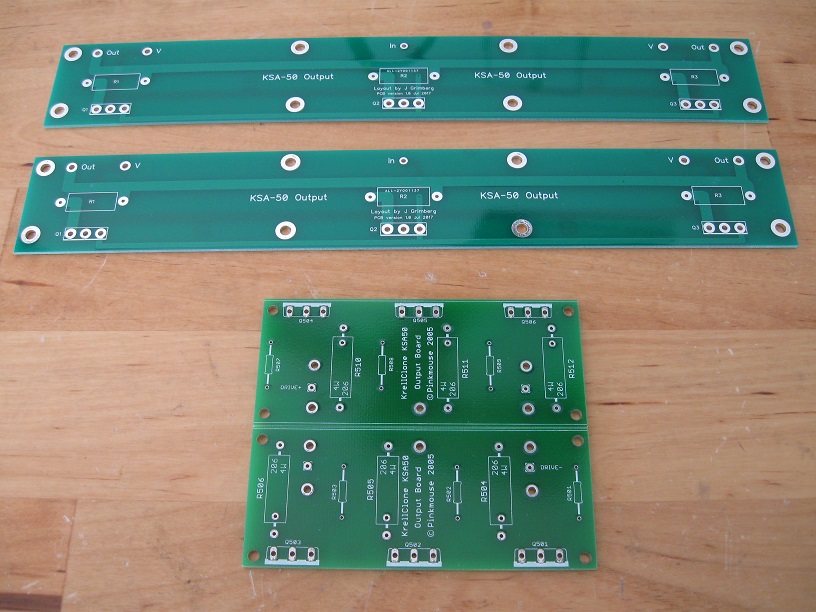

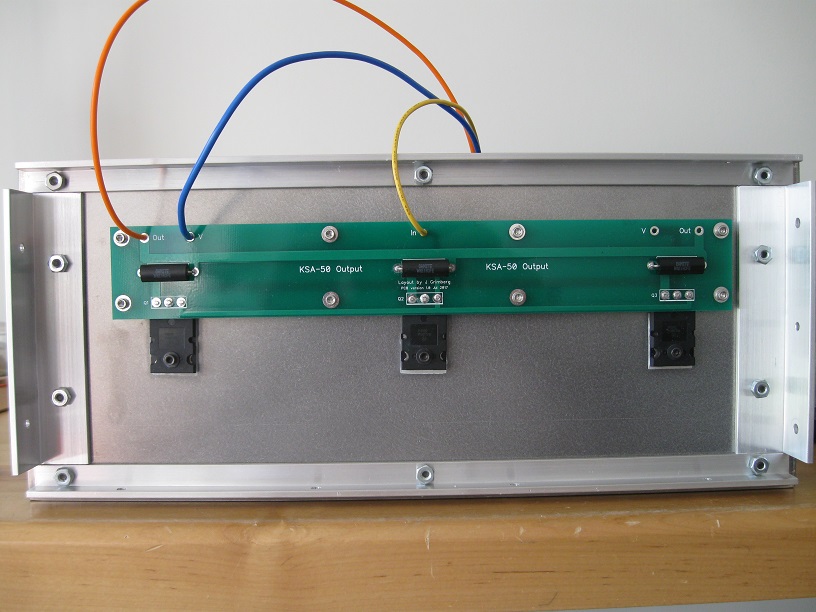

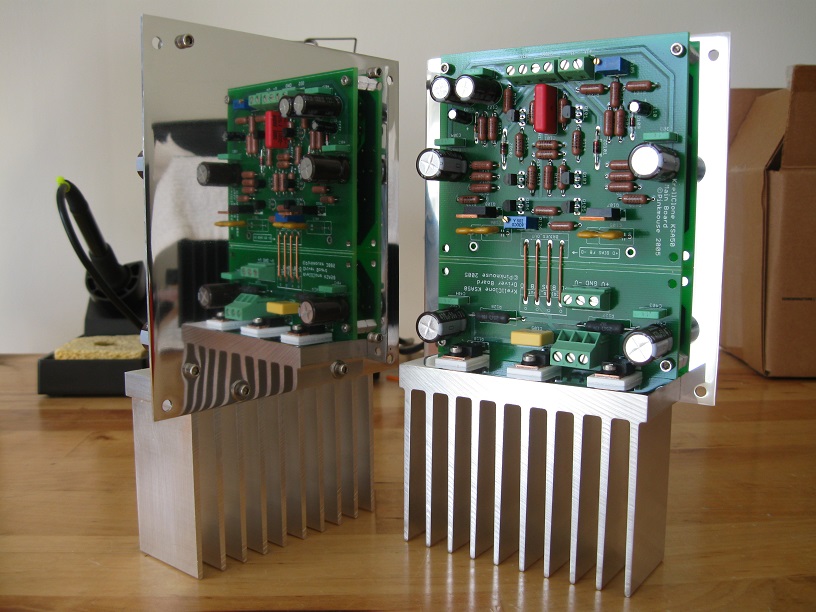

I designed a longer output PCB to better use the length of the heat sink. I made it so a single design can be used in either side of the case. Here are the new output boards next to the original ones, which I never used.

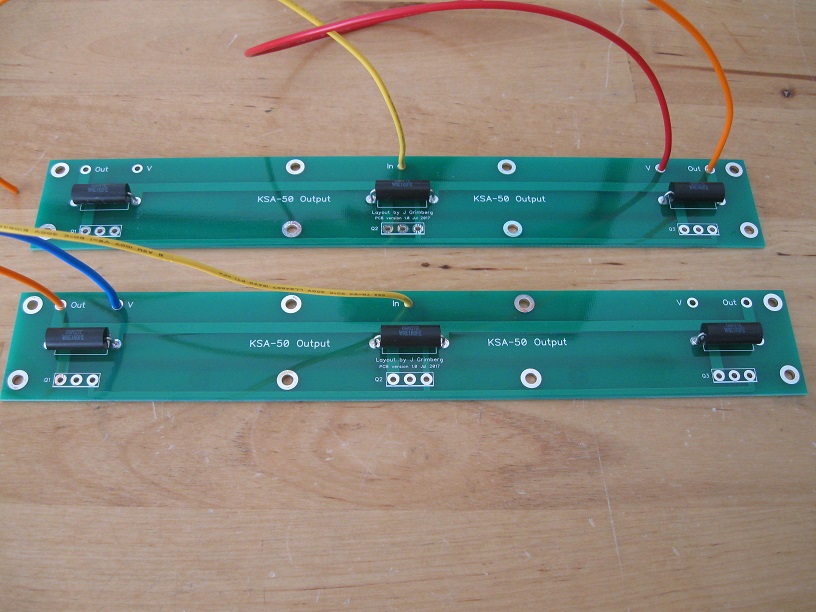

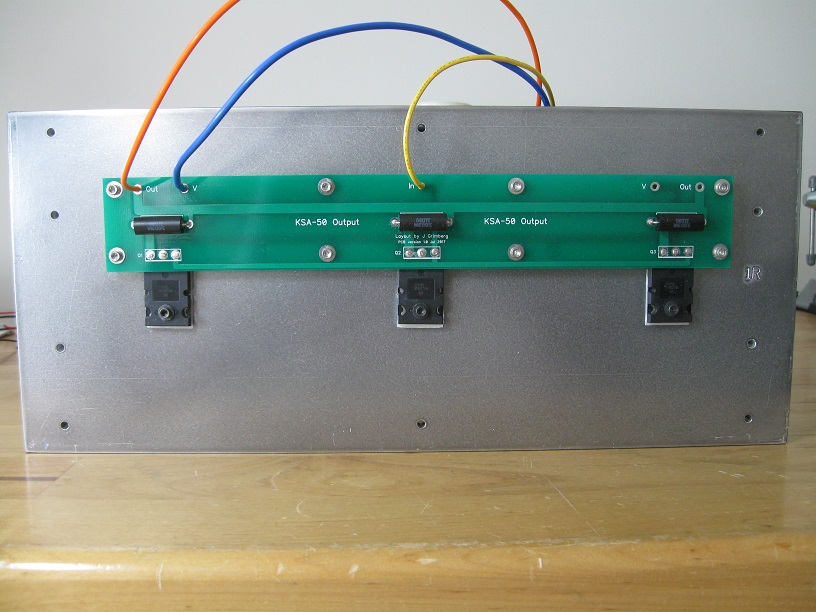

Output boards populated and then mounted on the heat sink.

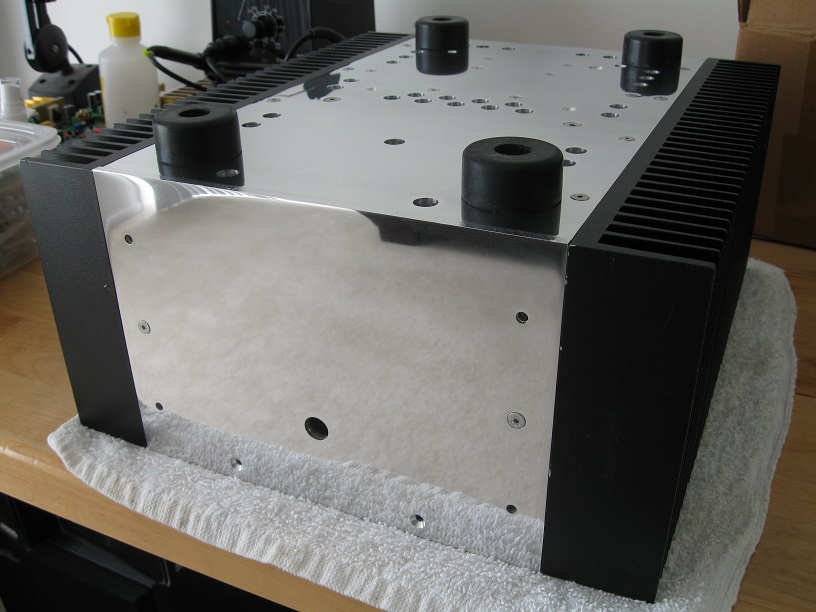

The aluminum brackets after the cleanup, mounted on the heat sink.

The bottom plate really clean (yeah, I went a little crazy on that one.

The best way I found to mount the bottom plate is to flip the heat sink and assemble everything upside down.

I then installed the front plate and the rubber feet.

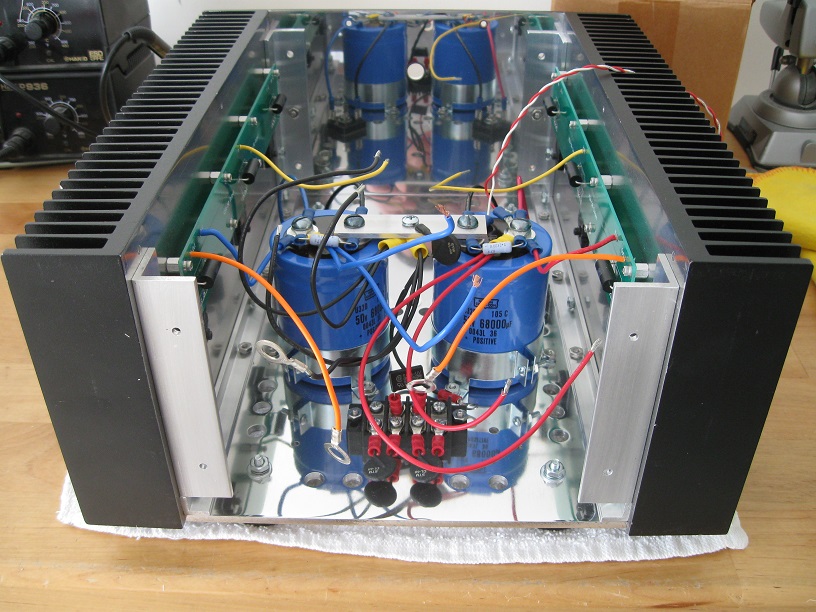

Next I reinstalled the capacitors and redid the wiring.

I completed my KSA-50 build in 2007. It took longer than I had planned and, combined with a job change and added daily commute time, I never put the final touch in the mono-blocs’ appearance. I decided they would get a makeover for their 10th anniversary, starting with a thorough cleaning of all the aluminum parts which still had Sharpie markings from the cutting and drilling steps. The makeover would also add long output boards to better use the length of the heat sinks, and front panels, which I never got to make back then.

After I had taken the units apart and cleaned up the aluminum panels, Troy posted this:

http://www.diyaudio.com/forums/solid-state/31077-krell-ksa-50-pcb-355.html#post5195136

I decided to take pictures of the makeover and post them, so he can hopefully enjoy them.

I designed a longer output PCB to better use the length of the heat sink. I made it so a single design can be used in either side of the case. Here are the new output boards next to the original ones, which I never used.

Output boards populated and then mounted on the heat sink.

The aluminum brackets after the cleanup, mounted on the heat sink.

The bottom plate really clean (yeah, I went a little crazy on that one.

The best way I found to mount the bottom plate is to flip the heat sink and assemble everything upside down.

I then installed the front plate and the rubber feet.

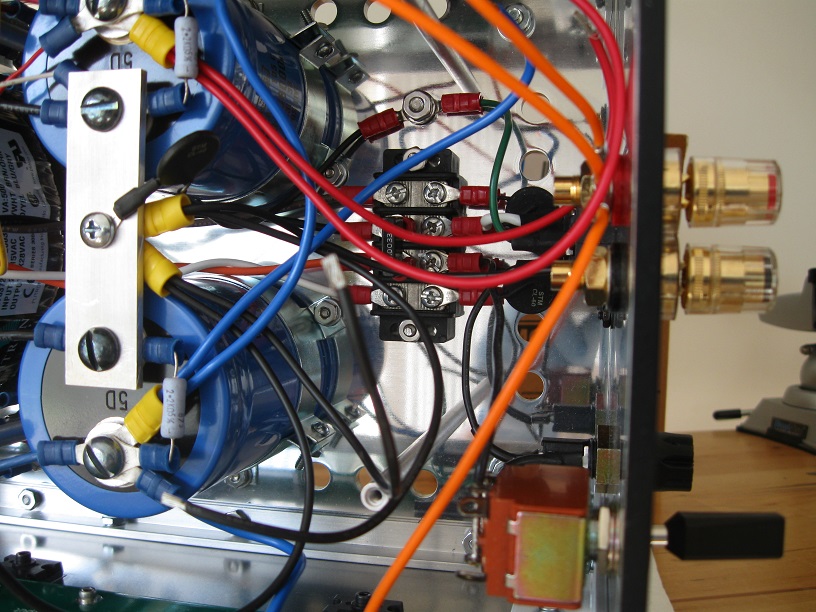

Next I reinstalled the capacitors and redid the wiring.

Attachments

-

Output_boards.jpg172.8 KB · Views: 1,777

Output_boards.jpg172.8 KB · Views: 1,777 -

Capacitors_mounted.jpg207 KB · Views: 1,970

Capacitors_mounted.jpg207 KB · Views: 1,970 -

Bottom_plate_mounted.jpg157.9 KB · Views: 1,669

Bottom_plate_mounted.jpg157.9 KB · Views: 1,669 -

Main_PCB_top_and_bottom.jpg164.1 KB · Views: 1,901

Main_PCB_top_and_bottom.jpg164.1 KB · Views: 1,901 -

Main_PCB_assembly.jpg207 KB · Views: 1,641

Main_PCB_assembly.jpg207 KB · Views: 1,641 -

Heatsink_with_brackets.jpg140 KB · Views: 1,703

Heatsink_with_brackets.jpg140 KB · Views: 1,703 -

Output_boards_mounted.jpg155.9 KB · Views: 1,603

Output_boards_mounted.jpg155.9 KB · Views: 1,603 -

Output_boards_populated.jpg158.9 KB · Views: 1,770

Output_boards_populated.jpg158.9 KB · Views: 1,770 -

Front_plate_mounted.jpg137 KB · Views: 1,584

Front_plate_mounted.jpg137 KB · Views: 1,584 -

Bottom_plate.JPG168 KB · Views: 1,621

Bottom_plate.JPG168 KB · Views: 1,621

10th anniversary makeover (continued)

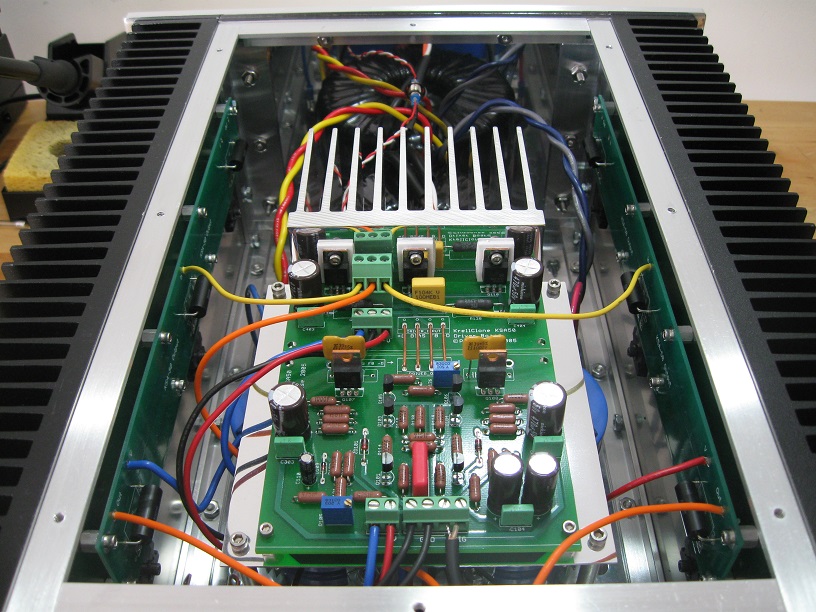

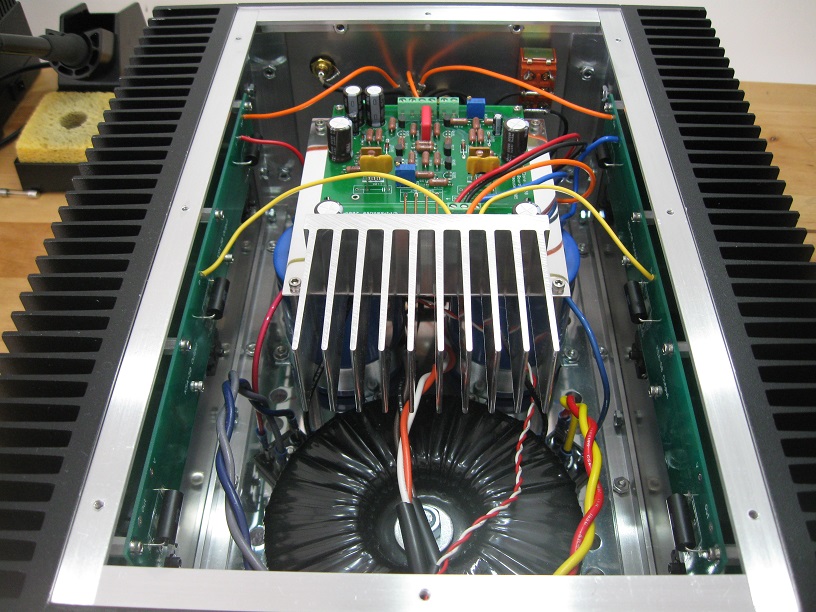

The main PCBs are mounted on an aluminum plate, supported by four standoffs attached to the bottom plate. I replaced the drivers' heat sink with a larger one.

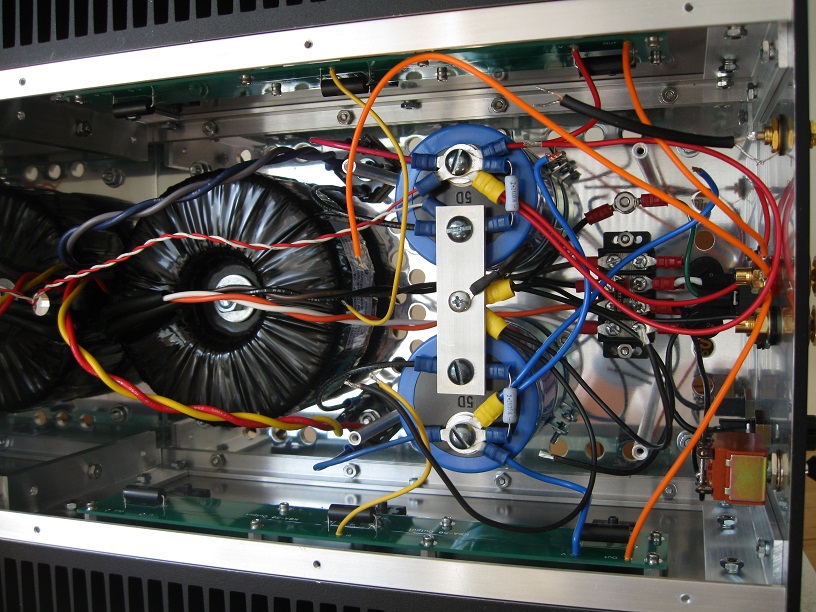

I reinstalled the transformer and connected it.

Next I put the PCB assembly back in its place.

And here is a view from the back.

A closeup of the connections on the bottom and back plates.

The newly created front panel

The back plate.

And the bottom plate

And finally, the mono-blocs complete, side-by-side.

The main PCBs are mounted on an aluminum plate, supported by four standoffs attached to the bottom plate. I replaced the drivers' heat sink with a larger one.

I reinstalled the transformer and connected it.

Next I put the PCB assembly back in its place.

And here is a view from the back.

A closeup of the connections on the bottom and back plates.

The newly created front panel

The back plate.

And the bottom plate

And finally, the mono-blocs complete, side-by-side.

Attachments

-

Two_units.JPG121.9 KB · Views: 1,551

Two_units.JPG121.9 KB · Views: 1,551 -

Two_fronts.jpg75.9 KB · Views: 1,430

Two_fronts.jpg75.9 KB · Views: 1,430 -

Back_plate.jpg105.6 KB · Views: 1,546

Back_plate.jpg105.6 KB · Views: 1,546 -

Front_panel.jpg104.9 KB · Views: 1,437

Front_panel.jpg104.9 KB · Views: 1,437 -

bottom.jpg126.5 KB · Views: 1,541

bottom.jpg126.5 KB · Views: 1,541 -

Connections.jpg205.4 KB · Views: 1,569

Connections.jpg205.4 KB · Views: 1,569 -

Main_PCB_back.jpg210.4 KB · Views: 1,593

Main_PCB_back.jpg210.4 KB · Views: 1,593 -

main_PCB.jpg220.9 KB · Views: 1,605

main_PCB.jpg220.9 KB · Views: 1,605 -

PSU_complete.jpg228.2 KB · Views: 1,588

PSU_complete.jpg228.2 KB · Views: 1,588 -

mono-bloc.jpg126.3 KB · Views: 1,551

mono-bloc.jpg126.3 KB · Views: 1,551

Last edited:

There is a plenum box it blows into and is lined with felt and it exits into a scouped out base that extends half way out underneath the heatsink area. This is enough to direct the air across all fins upward.

The way Grimberg has done it is the best quietest way of course, but at the time I didn,t have the sinks for natural convection and had these.

Don,t think for one second each heatsink can handle 3 outputs at full bias because they can,t and thus the fan is needed.

It is important that you run a fan well under 1000rpm and these are run just above the turn on voltage around 7 volts ( from memory)

Even in this particular arrangement, I can hear the fans slightly so would not really suggest this way but it was my thinking back then and went for it.

My 100 monos are fan cooled and you cannot hear them because inlet and outlet are protrusion free.

The last pic shows the 100 Mono. There are fins on the back side of each sink and blowing straight down lowered the on off temp 11c and just enough to keep proper bias temps on the TO 3 outputs of that build.

Moral of story , big sinks (grimberg) air convection and no noise or small sinks and smaller builds and slight sacrifice in fan rush depending on configuration

All good fun

Regards

David

Some pics

The way Grimberg has done it is the best quietest way of course, but at the time I didn,t have the sinks for natural convection and had these.

Don,t think for one second each heatsink can handle 3 outputs at full bias because they can,t and thus the fan is needed.

It is important that you run a fan well under 1000rpm and these are run just above the turn on voltage around 7 volts ( from memory)

Even in this particular arrangement, I can hear the fans slightly so would not really suggest this way but it was my thinking back then and went for it.

My 100 monos are fan cooled and you cannot hear them because inlet and outlet are protrusion free.

The last pic shows the 100 Mono. There are fins on the back side of each sink and blowing straight down lowered the on off temp 11c and just enough to keep proper bias temps on the TO 3 outputs of that build.

Moral of story , big sinks (grimberg) air convection and no noise or small sinks and smaller builds and slight sacrifice in fan rush depending on configuration

All good fun

Regards

David

Some pics

Attachments

Since 2008 I have been using fans made by Noctua (Fans - Products) to cool off my computers. They now have a 200mm fan which runs at 800 RPM and has a claimed noise level of 18.1 dB/A. Looks like a good candidate for cooling an amplifier.

Good suggestion on the Noctua NF20.Excelent product. Two models: PWM $50 and FLEX $30.

In addition, Antec have a good 3 velocity 200mm fan for $18.

From Antec files:

3 Speed Fan- Current: 0.08A, 0.17A, 0.3A- Speed: 400 rpm, 600 rpm, 800 rpm- Airflow: 83 cfm, 108 cfm, 134 cfm- Noise: 24 dBA, 27 dBA, 30 dBA

Rated Voltage -- 12V DC

Operating Voltage -- 10.8V ~ 13.2V

3-Speed switch lets you balance quiet performance with maximum cooling

In addition, Antec have a good 3 velocity 200mm fan for $18.

From Antec files:

3 Speed Fan- Current: 0.08A, 0.17A, 0.3A- Speed: 400 rpm, 600 rpm, 800 rpm- Airflow: 83 cfm, 108 cfm, 134 cfm- Noise: 24 dBA, 27 dBA, 30 dBA

Rated Voltage -- 12V DC

Operating Voltage -- 10.8V ~ 13.2V

3-Speed switch lets you balance quiet performance with maximum cooling

Last edited:

GB

The badges were made by a member in Europe back in that time period and he offered them one time only. It wasn,t a group buy, just everyone responding to a couple of posts he made while he was building his clone. They were CNC,d out of brushed metal clad Formica material. Back lighting was my design though.

The machining is nothing fancy and the handles are made of acrylic and painted. Just made a jig with a long laminate trim router held on with 5/16"-28 bolts.

The front panel was cut on a table saw , sanded, acid etched and clear coated.

The big fans that are now avaible are the best bet and were not around 10 years ago. I might even remake the 50 water to accept a couple of them. That air path design is still not optimum ,but bigger fans would lower noise contributions.

I am currently going to use them in an OTL /6c33 in the works.

They have the low speed torque to provide that low speed and super low noise.

The key to low noise is keeping the inlet clear , some distance from any objects in the path and a clear open area exiting and yes those big slow fans.

A pic of the downward blowing fan 100 mono build. 2 speed and no noise.

The badges were made by a member in Europe back in that time period and he offered them one time only. It wasn,t a group buy, just everyone responding to a couple of posts he made while he was building his clone. They were CNC,d out of brushed metal clad Formica material. Back lighting was my design though.

The machining is nothing fancy and the handles are made of acrylic and painted. Just made a jig with a long laminate trim router held on with 5/16"-28 bolts.

The front panel was cut on a table saw , sanded, acid etched and clear coated.

The big fans that are now avaible are the best bet and were not around 10 years ago. I might even remake the 50 water to accept a couple of them. That air path design is still not optimum ,but bigger fans would lower noise contributions.

I am currently going to use them in an OTL /6c33 in the works.

They have the low speed torque to provide that low speed and super low noise.

The key to low noise is keeping the inlet clear , some distance from any objects in the path and a clear open area exiting and yes those big slow fans.

A pic of the downward blowing fan 100 mono build. 2 speed and no noise.

Attachments

hi all, I find myself in the house two transformers from 500va one, 28.5 v for rail , 8 capacitors 22000 uf 63 v, and two audio delta cards clone ksa 50, now my problem is this I can not find official sellers the tr 2sa970 and 2sc2240, you confirm that I can replace them with ksa992 and ksc1845? do they sound the same way? I saw that there are those who use mje differences?

what tr power do you recommend in the case to-264, mjl21194 / 3 is the best? or which one? thank you all

what tr power do you recommend in the case to-264, mjl21194 / 3 is the best? or which one? thank you all

Pinkmouse KSA-50 PCBs

I have a pair of pinkmouse KSA-50 boards available. What would they be worth now? Add shipping and they're yours. I have a wonderful KSA-100 still kicking ash which I never push bias pass .365mv and never have to raise volume one quarter turn-don't want to blow out the windows. I use 1KVA transfos, so I have two sets of speaker. One with 12" woofers and the other with 15" woofers.

I built this amp because I lost my hearing in the Army so I have to ---FEEL--- the music. If these boards are too old and outdated I understand.

I have a pair of pinkmouse KSA-50 boards available. What would they be worth now? Add shipping and they're yours. I have a wonderful KSA-100 still kicking ash which I never push bias pass .365mv and never have to raise volume one quarter turn-don't want to blow out the windows. I use 1KVA transfos, so I have two sets of speaker. One with 12" woofers and the other with 15" woofers.

I built this amp because I lost my hearing in the Army so I have to ---FEEL--- the music. If these boards are too old and outdated I understand.

Attachments

Good suggestion on the Noctua NF20.Excelent product. Two models: PWM $50 and FLEX $30.

In addition, Antec have a good 3 velocity 200mm fan for $18.

From Antec files:

3 Speed Fan- Current: 0.08A, 0.17A, 0.3A- Speed: 400 rpm, 600 rpm, 800 rpm- Airflow: 83 cfm, 108 cfm, 134 cfm- Noise: 24 dBA, 27 dBA, 30 dBA

Rated Voltage -- 12V DC

Operating Voltage -- 10.8V ~ 13.2V

3-Speed switch lets you balance quiet performance with maximum cooling

I tried the Noctua NF-P12 and NF-S12 FLX. You have to consider how dense your fins are and how close the fan is to the array of heat sink fins in order to get the best fan type to match -static pressure fan (heatsink has high density of fins, fan is close) or normal PWM fan. I Did some experiments and found the normal one worked better for me. Also these fans are very quiet but the system will run about 5 or 10 C higher than with and old school noisy fast fan. And you really need a nice grill to not impede the airflow or you will add another 2-5 C to the system.

These fancy Noctua fans are not the cure all everyone holds them out to be, temps did rise as compared with my older, noiser, 'Aspire' fan. If you hold your hand over the Noctua, all the airflow seems to be going out by the edges, very little in the center, interesting...maybe this is how they keep the turbulence noise down.

You can see the latest here- Krell Clone 12 years later

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I recently looked at the data sheet for the MJL21193/94 to check what temps they can work at with the associated heat de-rating. I am no expert but after doing the math for temp derating, current, voltage, and thermal resistance to junction/case and case/heatsink, I concluded that 3 pairs per channel should be able to do the job at over 120 C 50W class A. I have 4 pairs per channel so the quiet Noctua fans running on a hot day at heatskink temp of 75C or even 80C should not bother me too much, but I would not use this amp on a hot day like that anyway. Think of the heatsinks as accepting tiny little blow torches at every transistor- like a creme brulee torch. The data sheet shows these devices operating at 150C which is pretty toasty.

I have a pair of pinkmouse KSA-50 boards available. What would they be worth now? Add shipping and they're yours. I have a wonderful KSA-100 still kicking ash which I never push bias pass .365mv and never have to raise volume one quarter turn-don't want to blow out the windows. I use 1KVA transfos, so I have two sets of speaker. One with 12" woofers and the other with 15" woofers.

I built this amp because I lost my hearing in the Army so I have to ---FEEL--- the music. If these boards are too old and outdated I understand.

Not sure what those would be worth but at this point one who wants to divest of the boards should figure out what errors are on there and point to the solution... identified and buried in this thread... I think there were a couple of issues with those?

Last edited:

To my knowledge there was no issues with the pink mouse boards ordered by Mark. The Jan boards had a unique potentiometer that was unobtainable so they needed to be modified slightly.Can you recall what issues with these boards as I can,t remember anything significant

Regards

David

- Home

- Amplifiers

- Solid State

- Krell KSA 50 PCB