Ian, Bigun, I don't pretend to understand the detail of what you are discussing, but it seems to me that in order to preserve the P3A character, it is necessary to:

- Retain the CFP VAS

- Stick to one pair of outputs

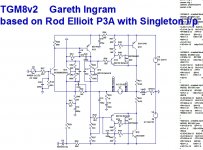

Isn't it enough to evaluate the effect of changing design element (i.e. LTP to singleton input)? It would be great to focus some efforts on the TGM8 BOM, so that it reflected the recommendations from Sarkis and others in the P3A thread, with the board layout component spacings to suit.

- Retain the CFP VAS

- Stick to one pair of outputs

Isn't it enough to evaluate the effect of changing design element (i.e. LTP to singleton input)? It would be great to focus some efforts on the TGM8 BOM, so that it reflected the recommendations from Sarkis and others in the P3A thread, with the board layout component spacings to suit.

You know, if you rearrange the input and output stage, it really is a different beast and will sound very difficult.

What about using a quasi output, and using monster fets? I have have very good experiences with quasi output stages; they increase H2 and H3 and sound very warm yet do not lose resolution. And if you use mosfets, you can use IRFP450, which is a 500V, 12A 200W mosfet.

Hugh

What about using a quasi output, and using monster fets? I have have very good experiences with quasi output stages; they increase H2 and H3 and sound very warm yet do not lose resolution. And if you use mosfets, you can use IRFP450, which is a 500V, 12A 200W mosfet.

Hugh

Member

Joined 2009

Paid Member

Well I have to agree with all the good advice about not detracting to much from the original design whose sound signature we still wish to capture. So we should leave the VAS alone. Which means it stays as the original, a simple single device.

As for the output stage, if I leave the MOSFET option in the design it can be built with or without them. Assembled without them and it will be just as the original. Having this option still appeals to me for now - I'll see if the pcb layout makes me change my mind on keeping it in.

BOM questions already - well then, which resistors do we want to maintain as through-hole to allow for special parts-tweaking, whilst the rest can be 1206 parts for a compact layout ?

I've uploaded the spice file for those who like to play - I will need to review the parts values a bit, especially the capacitors so that I size them correctly.

As for the output stage, if I leave the MOSFET option in the design it can be built with or without them. Assembled without them and it will be just as the original. Having this option still appeals to me for now - I'll see if the pcb layout makes me change my mind on keeping it in.

BOM questions already - well then, which resistors do we want to maintain as through-hole to allow for special parts-tweaking, whilst the rest can be 1206 parts for a compact layout ?

I've uploaded the spice file for those who like to play - I will need to review the parts values a bit, especially the capacitors so that I size them correctly.

Attachments

Last edited:

BOM questions already - well then, which resistors do we want to maintain as through-hole to allow for special parts-tweaking, whilst the rest can be 1206 parts for a compact layout ?

R27/R28 (VAS bootstrap) and R33 (Zobel) should have 10mm footprint so that 1W MOX or 0,5W Metal film TH resistors could fit. That's where we anticipate possible higher dissipation. Also, it would be nice to use 10mm footprints for signal input shunt and series resistors so that low noise metal film can be used in these positions too. I do not know if 1206 SMD is available as low noise metal film. If it is, than input resistors also could be SMD. 0R33 "emitter" resistors should have big footprints too, butr they can be vertically mounted to save pcb space.

Last edited:

Member

Joined 2009

Paid Member

The 0R33 resistors can also be SMT if we want, Hugh uses these on some of his designs (although not all of them) and they are fairly beefy. I've used the Dale WSR series 4527 sized parts, good for 2W and 1% tolerance.

The 1206 resistors I have used before are all (thick) metal film (Stackpole from Digikey), but some folk like to use other stuff. I'll start out with 1206. I have used larger sizes when higher power dissipation is needed so that should be fine with SMT also. For the zobel I do recommend a through-hole part just because.

Filter caps - OK.

dc-protection - I don't like relays because there are very few of them available that you can trust to open a high current to an inductive load. Some people say the contacts get dirty and affect small signal performance too. My preference is to make a solid-state relay from a pair of NMOSFETs. With very low Rds on they will have no influence on the signal, they turn on and off very fast and can switch all the load the current we need. They don't need to dissipate any power so we can use a pair of TO-220 or SMT packaged devices without any heatsinking.

Do we want base-stoppers on the output devices? or on the drivers ? Rod doesn't use them but I've always included them in the past with EF output stages but I've not used a CFP output before. ?

The 1206 resistors I have used before are all (thick) metal film (Stackpole from Digikey), but some folk like to use other stuff. I'll start out with 1206. I have used larger sizes when higher power dissipation is needed so that should be fine with SMT also. For the zobel I do recommend a through-hole part just because.

Filter caps - OK.

dc-protection - I don't like relays because there are very few of them available that you can trust to open a high current to an inductive load. Some people say the contacts get dirty and affect small signal performance too. My preference is to make a solid-state relay from a pair of NMOSFETs. With very low Rds on they will have no influence on the signal, they turn on and off very fast and can switch all the load the current we need. They don't need to dissipate any power so we can use a pair of TO-220 or SMT packaged devices without any heatsinking.

Do we want base-stoppers on the output devices? or on the drivers ? Rod doesn't use them but I've always included them in the past with EF output stages but I've not used a CFP output before. ?

Last edited:

dc-protection - I don't like relays because there are very few of them available that you can trust to open a high current to an inductive load. Some people say the contacts get dirty and affect small signal performance too.

Absolutely right! They degrade sound after only a few years and usually it is impossible to open them for cleaning. Only problems with them.

I think that we probably do not need base stopers.

Last edited:

Bigun, I like the idea of using a solid state relay - I've just never used them personally. Is this the sort of thing you are suggesting:

PSMN013-100BS,118 NXP Semiconductors | Mouser

How about those filter caps any ideas?

PSMN013-100BS,118 NXP Semiconductors | Mouser

How about those filter caps any ideas?

Probably more like this, from Bonsai:http://hifisonix.com/wordpress/wp-content/uploads/2012/08/Speaker-Relay-V1.03.pdf

Member

Joined 2009

Paid Member

This is another good and simple explanation: http://www.geofex.com/article_folders/ampprot/dcprot.htm

I used this approach myself here: http://www.diyaudio.com/forums/solid-state/196973-tgm5-all-bjt-simple-symmetric-amplifier-7.html

See also:

ESP - MOSFET Solid State Relays Rod Elliot has a lot of really good stuff on his webesite, it's a goldmine and pretty close to compulsory reading for DIY'ers. I have found a lot of helpful ideas and good practical advice there. And hey, this thread is based on his amplifier

Filter caps - I think it's going to be something based on the practicality of what fits onto the pcb. Really large caps that can't be placed close to the output stage aren't the best solution. You want the rail capacitors close to the output so that pcb traces are short with low inductance. I have read on the internet that this is particularly important with the CFP we'll be using here.

I used this approach myself here: http://www.diyaudio.com/forums/solid-state/196973-tgm5-all-bjt-simple-symmetric-amplifier-7.html

See also:

ESP - MOSFET Solid State Relays Rod Elliot has a lot of really good stuff on his webesite, it's a goldmine and pretty close to compulsory reading for DIY'ers. I have found a lot of helpful ideas and good practical advice there. And hey, this thread is based on his amplifier

Filter caps - I think it's going to be something based on the practicality of what fits onto the pcb. Really large caps that can't be placed close to the output stage aren't the best solution. You want the rail capacitors close to the output so that pcb traces are short with low inductance. I have read on the internet that this is particularly important with the CFP we'll be using here.

Last edited:

Interesting... I'll have a read through all that tonight. Those SSRs are very small compared to a mechanical relay. The TO-220 packages in particular occupy very little board space since they don't require heatsinking. This might be one area where TH is more compact than SMT.

I don't know why there aren't more DIYAUDIO designs with integral SSR speaker protections since it such an important function and requires little real estate.

I have a question about filter caps:

Can we have a CRC configuration comprising 4x 22mm caps and 3W resistors? Will there be enough board space?

By my calcs, 25VAC secondaries is approx. 33.6V rails produces 55W into 8R.

55W / 8R = 1.2Arms

Struth from this forum suggests that filter caps should have a current ripple rating with a factor of "3" (min.) or "6" (recommended.)

So the main filter caps should be rated 3.6 - 7.2Arms R.C @ 100/120hz per rail.

Looking at the Panasonic TS-UP series with 50V rating: http://www.mouser.com/ds/2/315/PIC_TS-UP_SERIES_DNE-180181.pdf

The 6.8mF can measures 22x50mm with 3.85Arms ripple rating. 2 of these per rail with a small 0.1R would be ideal, would you agree?

I don't know why there aren't more DIYAUDIO designs with integral SSR speaker protections since it such an important function and requires little real estate.

I have a question about filter caps:

Can we have a CRC configuration comprising 4x 22mm caps and 3W resistors? Will there be enough board space?

By my calcs, 25VAC secondaries is approx. 33.6V rails produces 55W into 8R.

55W / 8R = 1.2Arms

Struth from this forum suggests that filter caps should have a current ripple rating with a factor of "3" (min.) or "6" (recommended.)

So the main filter caps should be rated 3.6 - 7.2Arms R.C @ 100/120hz per rail.

Looking at the Panasonic TS-UP series with 50V rating: http://www.mouser.com/ds/2/315/PIC_TS-UP_SERIES_DNE-180181.pdf

The 6.8mF can measures 22x50mm with 3.85Arms ripple rating. 2 of these per rail with a small 0.1R would be ideal, would you agree?

One more request.... I notice there is no input cap on your schematic.

Could you add provision for a 10uF film cap on your layout? I'm quite partial to the EPCOS MKT cap that LC specifies for the VSSA.

It has a 15mm pin spacing.

B32522C106K EPCOS | Mouser

Could you add provision for a 10uF film cap on your layout? I'm quite partial to the EPCOS MKT cap that LC specifies for the VSSA.

It has a 15mm pin spacing.

B32522C106K EPCOS | Mouser

Member

Joined 2009

Paid Member

You got it dead right, a pair of TO-220 FETs will make for a compact solid state relay. Of course there will also need to be space for 2 or 3 transistors, the opto-isolator/driver and passive components to make a circuit that will detect dc at the output and activate the relay. I will include a delayed turn-on to prevent turn-on noises although rapid turn-off may not be accommodated.

I think it will be difficult to include a full CRC supply with the amplifier and dc protection as I will to limit myself to a pcb size that's 10cm x 8cm. I'll see how things develop once I get started.

As for input cap - no plans to include one. I have not been using input capacitors on most of my amplifiers these days. Besides, the amplifier will have dc protection on the output remember.

I think it will be difficult to include a full CRC supply with the amplifier and dc protection as I will to limit myself to a pcb size that's 10cm x 8cm. I'll see how things develop once I get started.

As for input cap - no plans to include one. I have not been using input capacitors on most of my amplifiers these days. Besides, the amplifier will have dc protection on the output remember.

Last edited:

Can you please make the board 74mm or less so us Aussies can mount it flat against a Conrad heatsink?

Bigun is using free version of Eagle pcb design software, therefore pcb will anyway be less than 80mm, and you will be able to mount it to standard 75mm heatsink extrusions.

Member

Joined 2009

Paid Member

- Home

- Amplifiers

- Solid State

- TGM8 - my best amplifier, incredible bass, clear highs, no fatigue (inspired by Rod Elliot P3a)