DX SUPER A

Thank you for your design Juan!nice etching mister thimios looks really good

Regards

Juan

DX SUPER A

I hope finish as soon as i can

Sorry for my bad English!

Thanks again .you are welcome

Regards

Juan

I hope finish as soon as i can

Sorry for my bad English!

Thank you very much Sir.

I have spent many hours and much money in handmade pcb.

Now i'm expert in handmade.

May I ask what technique you use for the etching? I would love to find a good method. I tried iron transfer but my Brother laser jet doesn't work well for that.

Thanks. Terry

May I ask what technique you use for the etching? I would love to find a good method. I tried iron transfer but my Brother laser jet doesn't work well for that.

Thanks. Terry

Looks to me like he uses my preferred method, the photographic method, assuming my eyes don't deceive me. Best results possible at home as far as I'm concerned. Correct me if I'm wrong.

DX SUPER A

Hi friends...yes i use the photographic method and i take special boards.I can give more details soon.

Best regards.

Looks to me like he uses my preferred method, the photographic method, assuming my eyes don't deceive me. Best results possible at home as far as I'm concerned. Correct me if I'm wrong.

Hi friends...yes i use the photographic method and i take special boards.I can give more details soon.

Best regards.

Last edited:

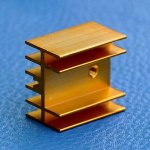

Heatsink

I found these Juan Small Size Aluminum Heat-Sink,

Gilded color, very beautiful.

For Package TO-220 Diodes, Transistors, Non-Inductive Resistors, LM78xx LM317 LM337 Regulator IC, etc.

M3 Screw Hole.

External Size: 15.2 x 25.4 x 23.4mm ( 0.6 x 1 x 0.92 inch).

I found these Juan Small Size Aluminum Heat-Sink,

Gilded color, very beautiful.

For Package TO-220 Diodes, Transistors, Non-Inductive Resistors, LM78xx LM317 LM337 Regulator IC, etc.

M3 Screw Hole.

External Size: 15.2 x 25.4 x 23.4mm ( 0.6 x 1 x 0.92 inch).

Attachments

Yes, Yes, Yes.Hi,

If we assume 42V rail and 6Ω speaker Re there will be 7A current over the fuse during a maximum DC output fault. 10A fuse will never blow during such conditions.

Much better to fuse the rails as fuse current rating could be halved. Rail fuses only take half period but the whole DC fault current.

He won't listen to me !

Really nice

Nice mister Eathguake I have those too they are just right in size they use to have those in black and silver but all run out, the golden ones comes with the M3 screw that depends on the seller too but any way really nice

they use to have those in black and silver but all run out, the golden ones comes with the M3 screw that depends on the seller too but any way really nice

Regards

Juan

I found these Juan Small Size Aluminum Heat-Sink,

Gilded color, very beautiful.

For Package TO-220 Diodes, Transistors, Non-Inductive Resistors, LM78xx LM317 LM337 Regulator IC, etc.

M3 Screw Hole.

External Size: 15.2 x 25.4 x 23.4mm ( 0.6 x 1 x 0.92 inch).

Nice mister Eathguake I have those too they are just right in size

Regards

Juan

DX SUPER A

Let's go to explain this.

Firt of all ... special material.Bungard photoresist board.

Second step.A high contrast film (high contrast black printed areas).

This is the most critical and difficult to make.3 options available.

1 photographic film ....difficult

2 photocopies in transparent film ...easier ....but this method give good results if transparents are high quality .We must use color transparents and color photomachine but we must print in black&white.

3 The easier and most cheep method. We must print on non-extended rice paper with a laser printer.With this method black isn't so black but we have the way to resolve this.

We must spray this non-extented rice paper with White Spirit.Now it's time to dry it with a hair dryer.

Now we have a high contrast Black&Withe film.

It's time for exposure.

We need ultraviolet radiation.

The easy method is to use LEDS.

These are cheep on the Ebay.

Order some of them 200 or 400.

See photo for details.

Exposure time is critical.In my case withe rice paper is 4 minuites

After the exposure it's time for development.

We need 9 gram. of caustic soda in 1 litre water.

Development time isn't so critical.If exposure is right we must see photoresist go out about 3 or 4 seconds after .

Attention......all photoresist must go out,3 or 4 minuites is ok.

Now wash pcb with plenty of water.

The final step is pcb etching.

There are many materials .I use Ferric chloride from bangurd.

Tryk .Put pcb in 45 angle and wetting with chloride continuasly.

When all is ok wash with plenty of water.

Attention. You must use gloves and glasses.

Good luck,

Hi friends...yes i use the photographic method and i take special boards.I can give more details soon.

Best regards.

Let's go to explain this.

Firt of all ... special material.Bungard photoresist board.

Second step.A high contrast film (high contrast black printed areas).

This is the most critical and difficult to make.3 options available.

1 photographic film ....difficult

2 photocopies in transparent film ...easier ....but this method give good results if transparents are high quality .We must use color transparents and color photomachine but we must print in black&white.

3 The easier and most cheep method. We must print on non-extended rice paper with a laser printer.With this method black isn't so black but we have the way to resolve this.

We must spray this non-extented rice paper with White Spirit.Now it's time to dry it with a hair dryer.

Now we have a high contrast Black&Withe film.

It's time for exposure.

We need ultraviolet radiation.

The easy method is to use LEDS.

These are cheep on the Ebay.

Order some of them 200 or 400.

See photo for details.

Exposure time is critical.In my case withe rice paper is 4 minuites

After the exposure it's time for development.

We need 9 gram. of caustic soda in 1 litre water.

Development time isn't so critical.If exposure is right we must see photoresist go out about 3 or 4 seconds after .

Attention......all photoresist must go out,3 or 4 minuites is ok.

Now wash pcb with plenty of water.

The final step is pcb etching.

There are many materials .I use Ferric chloride from bangurd.

Tryk .Put pcb in 45 angle and wetting with chloride continuasly.

When all is ok wash with plenty of water.

Attention. You must use gloves and glasses.

Good luck,

Attachments

Last edited:

DX SUPER A

My pleasure to help as i can.

Best regards.

Thimios.

Very good help for us.

regards,

Carlos

My pleasure to help as i can.

Best regards.

Thimios.

Juan Vargas has changed his Yahoo email adress

Now it is juanvargasdiaz1970@yahoo.com

regards,

Carlos

Now it is juanvargasdiaz1970@yahoo.com

regards,

Carlos

- Home

- Amplifiers

- Solid State

- Dx Blame ST together Dx Super A