A red house brick, smooth over the edges, but you would still need a fan.

Okay sounds good.

Yes Godfrey, you´re right - scroll down:

amplifiers vacuum tube systems hi-fi hihighend 6c33c triode SET OTL's

Karsten

amplifiers vacuum tube systems hi-fi hihighend 6c33c triode SET OTL's

Karsten

Make a loose, cylindrical coil, and put it in a jar of vegetable oil (several liters) with their axes aligned, hopefully convection will take care of the rest, or you might have a fire...

Wrap it around a hollow pyrex cylinder with water flowing through it.

They make this stuff for insulating kilns, wrap it around a tin can and then wrap the wire around that.

Wrap it around a hollow pyrex cylinder with water flowing through it.

They make this stuff for insulating kilns, wrap it around a tin can and then wrap the wire around that.

Last edited:

Is there no problem with corrosion of the wire?Yes Godfrey, you´re right - scroll down:

amplifiers vacuum tube systems hi-fi hihighend 6c33c triode SET OTL's

Karsten

Shorting of a winding - or two - will do no harm - except that your resistance will change. If I were to do such a test/measurement I would go for a ceramic tube - or rod. You can also use glass. Then I would wind the wire around the tube and maybe add a little high temperature glue to make the windings stay fixed. It is not difficult to find glue which can withstand up to 200 deg. C.

When testing with the "test-resistor" into (plenty? of) water you will not even come close to the boiling point - depending on the time, of course ;-).

Nichrome is corrosion-resistant and the most common alloy is 80% nickel and 20% chromium. In case you suspect it to corrode I would wipe it with a dry cloth right after the test. If this is not enough I would dry it afterwards with a hair-dryer.

Karsten

When testing with the "test-resistor" into (plenty? of) water you will not even come close to the boiling point - depending on the time, of course ;-).

Nichrome is corrosion-resistant and the most common alloy is 80% nickel and 20% chromium. In case you suspect it to corrode I would wipe it with a dry cloth right after the test. If this is not enough I would dry it afterwards with a hair-dryer.

Karsten

Ceramic.

Pyrex will likely crack if the wire ever gets red hot.

Glass will definitely crack if the wire ever gets red hot.

That is how glass rods and bottles are cut - score, heat nichrome wire - "tink" glass breaks on scored line.

No glue will work, it will quickly exceed the temp rating of any glue.

Nichrome wire is used in power resistors, they are made with ceramic and welded to the leads.

No ceramic?

Find an old toaster, take the mica out, use that.

Test the resistance of the toaster's nichrome first, might make things simpler to just use it.

Brick? Kinda big and clunky. Maybe ok.

Nichrome doesn't like to bend around sharp corners very much... better to have smooth transitions.

Mineral oil for cooling, or transformer oil if you want to get exotic... mineral oil is found in the drug store/pharmacy. You want a metal container for it so that the heat in the oil can be removed to the air...

Look at a "Heath Cantenna" - an inexpensive ham radio dummy load in a 1 gallon paint can. They used a carborundum resistance element in an oil bath... good for 1kw short term.

The advantage to cooling the nichrome is that you will get less resistance change with power in, as it varies with temperature in the wire.

Imo water is ng, it will boil way too low in temp, unless you have VERY fat nichrome wire that does not heat up...

Consider paralleling some rotisserie or electric oven elements instead, for a high power dummy load... almost free at the dump or in the street, and able to handle much more power, more in line with ur 740 watt requirement.

I doubt the 24ga nichrome will handle that much power. In fact I'd say, no way will it handle the power. Well yeah, if you let it glow red...

_-_-bear

PS. probably a 1.2kw electric heating element will work like this:

1200 = 120 x I = 10 amps 120 = 10 * R = 12 ohms It may be off a bit when cold, since the rating is when it is hot and the resistance varies when hot... so that is why you may need to parallel a few to get the resistance where you want it when more or less cold.

Pyrex will likely crack if the wire ever gets red hot.

Glass will definitely crack if the wire ever gets red hot.

That is how glass rods and bottles are cut - score, heat nichrome wire - "tink" glass breaks on scored line.

No glue will work, it will quickly exceed the temp rating of any glue.

Nichrome wire is used in power resistors, they are made with ceramic and welded to the leads.

No ceramic?

Find an old toaster, take the mica out, use that.

Test the resistance of the toaster's nichrome first, might make things simpler to just use it.

Brick? Kinda big and clunky. Maybe ok.

Nichrome doesn't like to bend around sharp corners very much... better to have smooth transitions.

Mineral oil for cooling, or transformer oil if you want to get exotic... mineral oil is found in the drug store/pharmacy. You want a metal container for it so that the heat in the oil can be removed to the air...

Look at a "Heath Cantenna" - an inexpensive ham radio dummy load in a 1 gallon paint can. They used a carborundum resistance element in an oil bath... good for 1kw short term.

The advantage to cooling the nichrome is that you will get less resistance change with power in, as it varies with temperature in the wire.

Imo water is ng, it will boil way too low in temp, unless you have VERY fat nichrome wire that does not heat up...

Consider paralleling some rotisserie or electric oven elements instead, for a high power dummy load... almost free at the dump or in the street, and able to handle much more power, more in line with ur 740 watt requirement.

I doubt the 24ga nichrome will handle that much power. In fact I'd say, no way will it handle the power. Well yeah, if you let it glow red...

_-_-bear

PS. probably a 1.2kw electric heating element will work like this:

1200 = 120 x I = 10 amps 120 = 10 * R = 12 ohms It may be off a bit when cold, since the rating is when it is hot and the resistance varies when hot... so that is why you may need to parallel a few to get the resistance where you want it when more or less cold.

Last edited:

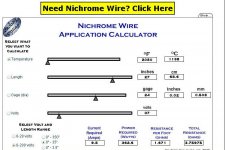

I found a Nichrome wire calculator, but it would not go up to 54 inches. So I used it at 27 inches at half power ( 360W). It gets a little warm. It does not melt though, if you put the voltage up too far the temperature will say "melt". Melting point 2552F.

Actually it does go to higher lengths I just noticed in the bottom left corner - Voltage and Length

selection-.

NichromeCalc

Actually it does go to higher lengths I just noticed in the bottom left corner - Voltage and Length

selection-.

NichromeCalc

Attachments

Last edited:

A long while back I needed nichrome wire to build a new slot car controller.

The cheapest at that time was to buy a replacement element for the infra red tubes.

Now I would go to a wire specialist.

The glue that we used was the sealing cement for car exhausts. The wire can go literally red hot and the cement still locates it in place and still prevents adjacent coils shorting.

The cheapest at that time was to buy a replacement element for the infra red tubes.

Now I would go to a wire specialist.

The glue that we used was the sealing cement for car exhausts. The wire can go literally red hot and the cement still locates it in place and still prevents adjacent coils shorting.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Amplifier Dummy Load Nichrome Wire