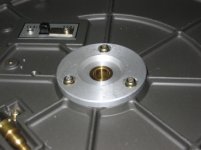

I think I need to replace a piece of my Pioneer PL-41's bearing. I don't know the correct terminology for everything, so bear with me. As it was assembled, the bottom of the spindle sits in a screw off cap on top of (from top to bottom) a plastic disc, two metal discs and finally the cap. The plastic disc appears to have shrunken and broken into several pieces. Because of the damage, I can't be sure if the plastic disc was solid and wore away, or if it had a conical divot in which the bottom of the spindle sat. Does anybody know what it should look like? Was that the order in which it was assembled originally? What should I replace the plastic disc with? I'm thinking teflon, but would any cheap easily procurred chunk of plastic do? Here are some pics to show the problem.

pj

pj

Attachments

Empire turntables use the same system

as do many others from the late 1950s and 60's

The plate should be made of DELRIN, and has a small indentation machined in it where the ball sits

There should be 2-3 teaspoons of oil in the bearing well

Its a simple repair and will last for decades if the turntable doesn't run out of oil

You could make and order the Part online here:

http://www.emachineshop.com/

Best

El Gippo

as do many others from the late 1950s and 60's

The plate should be made of DELRIN, and has a small indentation machined in it where the ball sits

There should be 2-3 teaspoons of oil in the bearing well

Its a simple repair and will last for decades if the turntable doesn't run out of oil

You could make and order the Part online here:

http://www.emachineshop.com/

Best

El Gippo

Thank you very much. The indentation is the key detail for me. I was planning to just buy a sheet of something and cut a circle myself. However, getting the indentation right in the center might best be done by a machine shop. I'll look around locally, but I may well use those guys to whom you linked.

pj

pj

You're welcome!

BTW, I should mention I own a Pioneer PL turntable from the mid 1960s that has the same spindle/bearing setup

If you download the emachineshop software, which is v. easy to use, input the measurements you need and the material, you can order that part online

The dimple in the Delrin is just that; its only 1.0mm across when these are new

I'm sure its only to allow a little oil to sit directly under the hardened steel ball that's welded to the spindle

By careful measurement and centre-punching the Delrin as a guide, there's no reason why you couldn't make that dimple yourself by hand with an "egg beater" hand drill or the end of a file, the indentation is spherical, so just the tip of a drill touching the Delrin for a second would do the trick

Delrin isn't hard like perspex, it's more like nylon, + has a bit of give

Nice turntable: check the rubber grommets that hold the motor, these decay and that causes vibration ( easily replaced )

The platter could do with a Mat or some damping material 'cos these are cast aluminum and ring like a bell

A little bit of minor maintenance + tweaking and you'll have a very fine turntable!

Best

El Gippo

BTW, I should mention I own a Pioneer PL turntable from the mid 1960s that has the same spindle/bearing setup

If you download the emachineshop software, which is v. easy to use, input the measurements you need and the material, you can order that part online

The dimple in the Delrin is just that; its only 1.0mm across when these are new

I'm sure its only to allow a little oil to sit directly under the hardened steel ball that's welded to the spindle

By careful measurement and centre-punching the Delrin as a guide, there's no reason why you couldn't make that dimple yourself by hand with an "egg beater" hand drill or the end of a file, the indentation is spherical, so just the tip of a drill touching the Delrin for a second would do the trick

Delrin isn't hard like perspex, it's more like nylon, + has a bit of give

Nice turntable: check the rubber grommets that hold the motor, these decay and that causes vibration ( easily replaced )

The platter could do with a Mat or some damping material 'cos these are cast aluminum and ring like a bell

A little bit of minor maintenance + tweaking and you'll have a very fine turntable!

Best

El Gippo

Thank you PJ for this question & photos.

I purchased a PL-41 several days ago and wouldn't have known that I needed a bearing. Your posting came up when I googled PL-41. My bearing looks just like yours.

Please let us know what route you take in making/purchasing the bearing.

Thanks to El Gippo for the great info.

Just to clarify, it is just a 1mm dimple, not through the material?

Also, the motor has an oil wick, will 3in1 oil do?

Would appreciate any additional advice on this fine machine.

OB

I purchased a PL-41 several days ago and wouldn't have known that I needed a bearing. Your posting came up when I googled PL-41. My bearing looks just like yours.

Please let us know what route you take in making/purchasing the bearing.

Thanks to El Gippo for the great info.

Just to clarify, it is just a 1mm dimple, not through the material?

Also, the motor has an oil wick, will 3in1 oil do?

Would appreciate any additional advice on this fine machine.

OB

The Electric Gypsie replies

El Gippo takes a Bow

2-3 teaspoons of a multigrade engine oil like 20W-50 will do the trick for the *spindle*

3-in-1 Oil is too light for this application, but it's OK for the motor ( just use a couple drops tho' )

The dimple does *not* go all the way through the material on an Empire or Pioneer turntable and the Delrin rests at the bottom of the bearing well with the screw-on metal cap supporting it

I would make the Delrin thrustplate between 1/8th and 1/4 in thick, and the same size as the internal diameter of the bearing well, so it's a "press-in-with-your-thumbs" fit

Thickness of the Delrin will affect the "ride height" of the platter; that isn't that critical in this application as you'll see; you may need to adjust the ride-height of the tonearm ( which you would do if you were fitting a new Cartridge, for e.g. ) *No Biggie*

Put some gasket goop or silicon sealer at the top of the screw-on cap where it meets the turntable body to save oil leaking out of there; going dry is how the Pioneer thrustplate collapsed and caused the problem

That won't have damaged the spindle or spindle ball, the thrustplates are designed to be sacrificial in these old designs; no harm done

*ReOil the spindle every 5-10 years, having cleaned out the bearing well 1st

*Replace the Delrin thrustplate every other lifetime ( make a note on your 2090 PalmPilot now; so you don't forget )

)

El Gippo

El Gippo takes a Bow

2-3 teaspoons of a multigrade engine oil like 20W-50 will do the trick for the *spindle*

3-in-1 Oil is too light for this application, but it's OK for the motor ( just use a couple drops tho' )

The dimple does *not* go all the way through the material on an Empire or Pioneer turntable and the Delrin rests at the bottom of the bearing well with the screw-on metal cap supporting it

I would make the Delrin thrustplate between 1/8th and 1/4 in thick, and the same size as the internal diameter of the bearing well, so it's a "press-in-with-your-thumbs" fit

Thickness of the Delrin will affect the "ride height" of the platter; that isn't that critical in this application as you'll see; you may need to adjust the ride-height of the tonearm ( which you would do if you were fitting a new Cartridge, for e.g. ) *No Biggie*

Put some gasket goop or silicon sealer at the top of the screw-on cap where it meets the turntable body to save oil leaking out of there; going dry is how the Pioneer thrustplate collapsed and caused the problem

That won't have damaged the spindle or spindle ball, the thrustplates are designed to be sacrificial in these old designs; no harm done

*ReOil the spindle every 5-10 years, having cleaned out the bearing well 1st

*Replace the Delrin thrustplate every other lifetime ( make a note on your 2090 PalmPilot now; so you don't forget

)

)El Gippo

I wouldn't bother with the dimple you describe in the thrust pad. Delrin would be a good choice but it didn't exist when your turntable was made - Nylon is probably the material used and the dimple will largely be the effect of wear. The dimple serves no useful purpose if the bearing sleeves are dimensionaly accurate - if, however, they are rather 'sloppy' the dimple will be centering the bearing to a point (no pun intended).

El Gippo replies

Disagree, and here's why:

I'm in possibly a unique position to comment; having owned both an Empire 208 and a Pioneer PL 12 which were both NOS ( actually new in the box ) as well as numerous turntables that were used that have this construction

Both very similar build to the PL 41 mentioned here, and while I had always assumed the "dimple" in the bottom of the bearing well had been worn there by the hardened ball in the spindle, in fact the manufacturer had machined one there when these were new in both the Empire and the PL 12

I'd suggest its just to trap a drop of oil so the spindle ball never contacts the thrust plate completely dry; engineering overkill, a valid theory, or otherwise, that's how they did it when these were New

While a material like phosphor bronze will soak up oil like a sponge ( as will cast iron ) these wouldn't make good materials for a thrust plate here because these would wear too fast, and would be hard enough to damage the hardened spindle ball over time

The nylon/Delrin doesn't have particularly good oil absorption properties, hence adding the dimple, but Delrin to is too soft to damage the spindle by contact over time

You are 100% correct that Delrin wasn't available back then, and that nylon was. Delrin was mentioned as it's proved to be a superior material for this repair and won't wear out anywhere near as quickly as replacing the original nylon part with nylon

The Electric Gypsy

Disagree, and here's why:

I'm in possibly a unique position to comment; having owned both an Empire 208 and a Pioneer PL 12 which were both NOS ( actually new in the box ) as well as numerous turntables that were used that have this construction

Both very similar build to the PL 41 mentioned here, and while I had always assumed the "dimple" in the bottom of the bearing well had been worn there by the hardened ball in the spindle, in fact the manufacturer had machined one there when these were new in both the Empire and the PL 12

I'd suggest its just to trap a drop of oil so the spindle ball never contacts the thrust plate completely dry; engineering overkill, a valid theory, or otherwise, that's how they did it when these were New

While a material like phosphor bronze will soak up oil like a sponge ( as will cast iron ) these wouldn't make good materials for a thrust plate here because these would wear too fast, and would be hard enough to damage the hardened spindle ball over time

The nylon/Delrin doesn't have particularly good oil absorption properties, hence adding the dimple, but Delrin to is too soft to damage the spindle by contact over time

You are 100% correct that Delrin wasn't available back then, and that nylon was. Delrin was mentioned as it's proved to be a superior material for this repair and won't wear out anywhere near as quickly as replacing the original nylon part with nylon

The Electric Gypsy

I'll call around town tomorrow and see if I can find someone to make the part. I really like this table. My wife (then young girlfriend) found it at a garage sale (for free with a broken belt), suspected I'd like it, and carried it an awfully long way home. It's built like a brick sh**house. I just replaced the stock tonearm with one from a Music Hall MMF2 (I put a new hole in the plinth). The stock arm seemed too heavy to provide a good compliance match for modern cartridges and the bearings are tough to adjust just right.

Unfortunately, I've always experianced some speed instability with this thing. I bought a manual for it on ebay a few years back, and it blames any speed problems on either a dirty belt/platter/pulley or a poorly lubricated bearing. I'm hoping that the completely broken thrust plate may have something to do with it, as I've covered the other bases. If it isn't the problem, I'll be looking closely at the motor.

I'll let you know how the thrust plate turns out.

pj

Unfortunately, I've always experianced some speed instability with this thing. I bought a manual for it on ebay a few years back, and it blames any speed problems on either a dirty belt/platter/pulley or a poorly lubricated bearing. I'm hoping that the completely broken thrust plate may have something to do with it, as I've covered the other bases. If it isn't the problem, I'll be looking closely at the motor.

I'll let you know how the thrust plate turns out.

pj

El Gippo

yeah, these are a real sleeper of a turntable; I have owned several so I'm familiar enough with these to comment: ( my latest PL 12 is being made into a record cleaning machine, mine also cost me nothing )

Check the Belt: wrong length and/or stretched is No Go

Dust in the motor/poor lubrication, failed grommets ( very common, 'cos these are OLD )

Lack of oil in the bearing well + failed thrust plate

*and any combination of the above*

will cause the speed instability you've observed

It's quite possible you've yet to hear the Pioneer at its best

Its quite a heavy platter so I'll add one more: *level* the Pioneer with a small spirit�@level so the platter is level against gravity, don't worry if the rest of the turntable is level or not, s'long as the platter is. Makes it easier for the belt and motor to do its thing

Good Luck!

The Electric Gypsy

yeah, these are a real sleeper of a turntable; I have owned several so I'm familiar enough with these to comment: ( my latest PL 12 is being made into a record cleaning machine, mine also cost me nothing )

Check the Belt: wrong length and/or stretched is No Go

Dust in the motor/poor lubrication, failed grommets ( very common, 'cos these are OLD )

Lack of oil in the bearing well + failed thrust plate

*and any combination of the above*

will cause the speed instability you've observed

It's quite possible you've yet to hear the Pioneer at its best

Its quite a heavy platter so I'll add one more: *level* the Pioneer with a small spirit�@level so the platter is level against gravity, don't worry if the rest of the turntable is level or not, s'long as the platter is. Makes it easier for the belt and motor to do its thing

Good Luck!

The Electric Gypsy

I had a large enough piece of the thrust plate left to put a caliper on, and it measured .083" in thickness.

But as you mentioned, any variation can be compensated for by adjusting the tonearm height.

I don't have a Palm Pilot so maybe I will apply a label advising the next change is due in 2090 (like an oil change sticker).

7/8" dia Delrin rod is available but I haven't yet figured out how I am going to cut off a .083" slice on my woodworking lathe...

Pj, if you find a source to make the part locally, would appreciate you sharing that info.

OB

But as you mentioned, any variation can be compensated for by adjusting the tonearm height.

I don't have a Palm Pilot so maybe I will apply a label advising the next change is due in 2090 (like an oil change sticker).

7/8" dia Delrin rod is available but I haven't yet figured out how I am going to cut off a .083" slice on my woodworking lathe...

Pj, if you find a source to make the part locally, would appreciate you sharing that info.

OB

I took the cap to a machine shop today and they cut a plate out of a delrin rod. It cost me $12.36. I had looked at ordering a sheet, but many places have minimum orders. I was also concerned about my ability to put a dimple right in the center without access to a drill press. I'll get the table back together and see where things stand.

pj

pj

Update on my project, with a question:

I ordered and received a 12" length of 7/8" diameter delrin rod from McMaster Carr.

Took the rod to a friend who owns a machine shop and he cut off several .083" slices for me.

I used a center punch with a light blow from a hammer to create a 1mm diameter dimple.

Put the 3 metal spacers in the threaded cap, added the delrin plate, and added oil per the Electric Gypsy's instructions.

However, here's the observation/question:

It appears that the metal spacers are slick enough with oil that the whole assembly spins in the cap. (Of course I have no way of knowing if this happens when assembled to the table, although the inside bottom of the cap where the lower metal spacer rests does show wear.)

I could have started with a larger diameter rod and machined it so it would be force-fit into the cap so that the assembly would not spin, but the original does not appear to have been done that way.

I have experimented with removing all the metal spacers and substituting an O-ring of the same approximate height on which the delrin rests. This prevents the delrin from spinning.

Seems to work, comments please.

OB

I ordered and received a 12" length of 7/8" diameter delrin rod from McMaster Carr.

Took the rod to a friend who owns a machine shop and he cut off several .083" slices for me.

I used a center punch with a light blow from a hammer to create a 1mm diameter dimple.

Put the 3 metal spacers in the threaded cap, added the delrin plate, and added oil per the Electric Gypsy's instructions.

However, here's the observation/question:

It appears that the metal spacers are slick enough with oil that the whole assembly spins in the cap. (Of course I have no way of knowing if this happens when assembled to the table, although the inside bottom of the cap where the lower metal spacer rests does show wear.)

I could have started with a larger diameter rod and machined it so it would be force-fit into the cap so that the assembly would not spin, but the original does not appear to have been done that way.

I have experimented with removing all the metal spacers and substituting an O-ring of the same approximate height on which the delrin rests. This prevents the delrin from spinning.

Seems to work, comments please.

OB

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Pioneer PL-41 bearing help