I was in the process of redoing my boxes. And i noticed about 3 of my mids, have very small dents/scratches. Pictures below can be seen.

I was just wondering if this will be audible?

And how can I test the impact of them to see if they are still working as intended to?

I was thinking of measuring all the mids against the one that I know is in perfect form. Should I do it 1" away like with subwoofers? Or should I do it 1 meter?

I was just wondering if this will be audible?

And how can I test the impact of them to see if they are still working as intended to?

I was thinking of measuring all the mids against the one that I know is in perfect form. Should I do it 1" away like with subwoofers? Or should I do it 1 meter?

Attachments

-

WhatsApp Image 2020-05-21 at 5.08.44 PM.jpeg197.1 KB · Views: 248

WhatsApp Image 2020-05-21 at 5.08.44 PM.jpeg197.1 KB · Views: 248 -

WhatsApp Image 2020-05-21 at 5.08.49 PM (1).jpeg94.8 KB · Views: 91

WhatsApp Image 2020-05-21 at 5.08.49 PM (1).jpeg94.8 KB · Views: 91 -

WhatsApp Image 2020-05-21 at 5.08.49 PM.jpeg156 KB · Views: 246

WhatsApp Image 2020-05-21 at 5.08.49 PM.jpeg156 KB · Views: 246 -

WhatsApp Image 2020-05-21 at 5.08.47 PM (1).jpeg299.8 KB · Views: 220

WhatsApp Image 2020-05-21 at 5.08.47 PM (1).jpeg299.8 KB · Views: 220 -

WhatsApp Image 2020-05-21 at 5.08.45 PM.jpeg195.3 KB · Views: 321

WhatsApp Image 2020-05-21 at 5.08.45 PM.jpeg195.3 KB · Views: 321 -

WhatsApp Image 2020-05-21 at 5.08.45 PM (1).jpeg182.8 KB · Views: 246

WhatsApp Image 2020-05-21 at 5.08.45 PM (1).jpeg182.8 KB · Views: 246

Last edited:

I was in the process of redoing my boxes. And i noticed about 3 of my mids, have very small dents/scratches. Pictures below can be seen.

I was just wondering if this will be audible?

And how can I test the impact of them to see if they are still working as intended to?

I was thinking of measuring all the mids against the one that I know is in perfect form. Should I do it 1" away like with subwoofers? Or should I do it 1 meter?

OK this will sound silly. When I crush Coke cans, the ones with no dents will support my 180 pounds.

The ones with a minor dent collapse much easier. I expect your speakers will behave similarly. At low

to modest levels no discernable results. At high to very high levels the cone may misbehave. Will it

be audible? I doubt I could hear it.

G²

Any imperfections in my speaker drive units annoy me, but I am finding it difficult to see the dents/scratches to which you refer.

If they're not particularly visible at the resolution of your photographs, I would be inclined not to worry about them.

By all means do some comparative measurements, one metre out seems reasonable.

If they're not particularly visible at the resolution of your photographs, I would be inclined not to worry about them.

By all means do some comparative measurements, one metre out seems reasonable.

I might get in trouble for this, but I have to ask if some of you are BLIND!

Clearly a fracture problem with these Zaph ZA14W08 woofers. Also possibly using old worn-out moulds. Does it matter?

Back in the day, de Havilland unveiled the terrifically shiny de Havilland Comet Aeroplane. Unfortunately, "Widowmaker" might have been a better name.

The wings fell off after a few flights. This was not good. We started to understand metal-fatigue.

TBH, a speaker blowing is generally less catastrophic than an aeroplane crashing.

This is where I might offend some of you, I'd generally trust Michael Chua more than Zaph on crossovers: Swift 2.5 (Zaph ZA14W08 with Peerless DQ25SC16-04) – AmpsLab

Onwards and upwards. Or as the RAF say: "Per Ardua, ad Astra."

Clearly a fracture problem with these Zaph ZA14W08 woofers. Also possibly using old worn-out moulds. Does it matter?

Back in the day, de Havilland unveiled the terrifically shiny de Havilland Comet Aeroplane. Unfortunately, "Widowmaker" might have been a better name.

The wings fell off after a few flights. This was not good. We started to understand metal-fatigue.

TBH, a speaker blowing is generally less catastrophic than an aeroplane crashing.

This is where I might offend some of you, I'd generally trust Michael Chua more than Zaph on crossovers: Swift 2.5 (Zaph ZA14W08 with Peerless DQ25SC16-04) – AmpsLab

Onwards and upwards. Or as the RAF say: "Per Ardua, ad Astra."

As subtle as a brick as usual Steve!I might get in trouble for this, but I have to ask if some of you are BLIND!

Yes, I CAN see that particular ding, even though I'm currently BLIND DRUNK!

Well, bless you my son. If anybody isn't drinking more, or self-medicating as my niece says, they don't know what is going on!

I can do Science, but right now, we probably need spirit more than anything.

I like Leonard Cohen: YouTube

Anoushka Shankar is ridiculously talented: YouTube

And for you Scots, I always admired yon Dougie MacLean: YouTube

Don't know if Cal Weldon will make me suffer for this post. Personally, I consider him a friend. We'll be alright.

I can do Science, but right now, we probably need spirit more than anything.

I like Leonard Cohen: YouTube

Anoushka Shankar is ridiculously talented: YouTube

And for you Scots, I always admired yon Dougie MacLean: YouTube

Don't know if Cal Weldon will make me suffer for this post. Personally, I consider him a friend. We'll be alright.

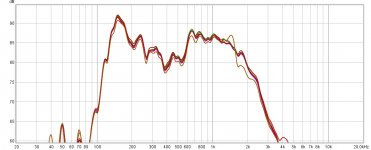

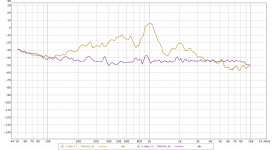

Firstly, all of the measurements were done in the same exact conditions. I had it in my enclosure, with one of the mids and tweeter removed from it, so there were 2 big holes. And I wired it to the upper mid on the crossover. Not sure if I got the polarity right as it was supposed to be on the crossover, but I did use the same polarity throughout this test. 10" away, pointed right at the mid.

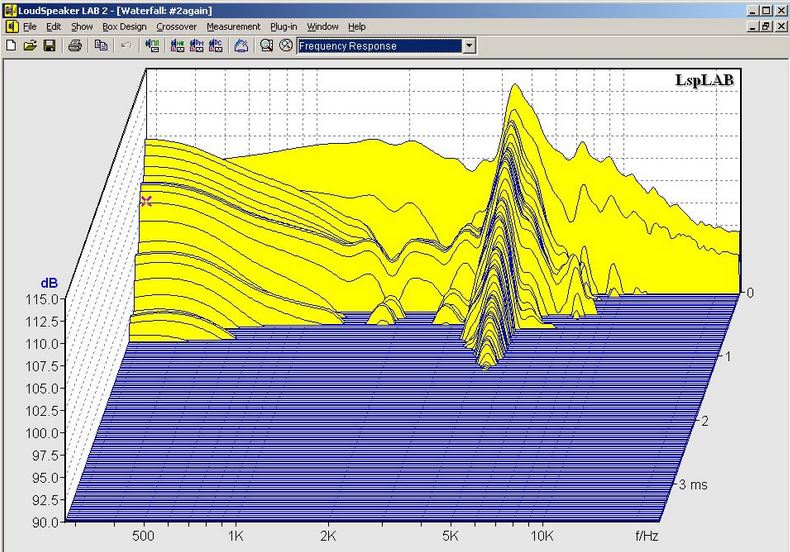

So basically. You were all right. There was no impact that I could find from the small dent/line/dinged unit based on measurements.

Here is what happened though.

I took my FIRST mid, which was totally okay. Measured it. Got a response.

Took my SECOND mid, which was also totally okay. Got a response, with a 5db dip.

Not knowing which one is correct, I kept going through all of them.

The one with the scratch/dent and all others matched my FIRST measurement.

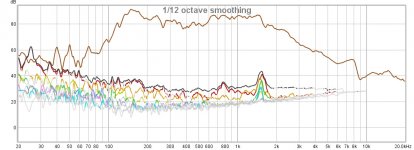

Now this is totally bothering me. The mid that shows no physical damage or anything upon inspection, shows a 5db drop around 1500hz and has higher distortion too.

Graphs are here.

Distortion graphs are of one of the normal mids and the other with the dip.

So basically. You were all right. There was no impact that I could find from the small dent/line/dinged unit based on measurements.

Here is what happened though.

I took my FIRST mid, which was totally okay. Measured it. Got a response.

Took my SECOND mid, which was also totally okay. Got a response, with a 5db dip.

Not knowing which one is correct, I kept going through all of them.

The one with the scratch/dent and all others matched my FIRST measurement.

Now this is totally bothering me. The mid that shows no physical damage or anything upon inspection, shows a 5db drop around 1500hz and has higher distortion too.

Graphs are here.

Distortion graphs are of one of the normal mids and the other with the dip.

Attachments

You'd expect the quality control on a $50 5" metal driver to be quite good.

The dents do look merely cosmetic. But the duff driver is clearly doing something bad. A full frequency response without filter might tell you more.

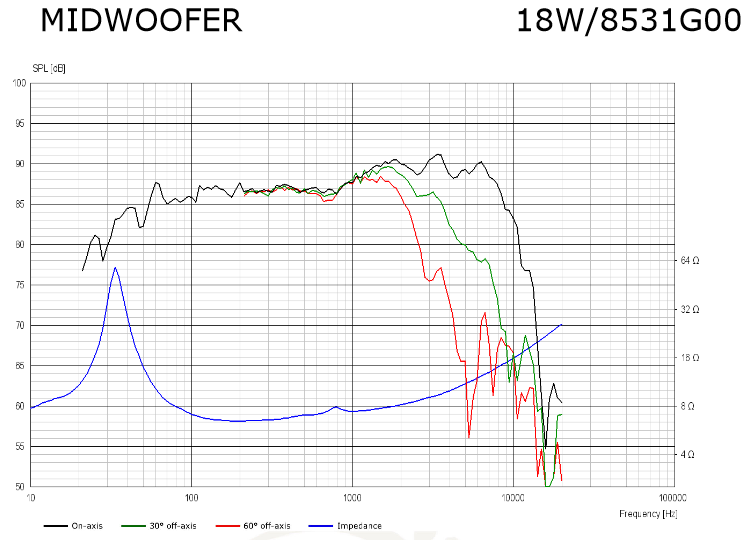

You've got Michael Chua's measurements to compare:

Swift 2.5 (Zaph ZA14W08 with Peerless DQ25SC16-04) – AmpsLab

1.5kHz is the region where surrounds and corrugated spiders cause distortion. Maybe too much glue? Maybe a rubbing voicecoil.

Rubbing voicecoils are usually easy to feel with a bit of prodding and pushing. The cure is often to rotate the driver. Not unknown for a bit of ferrite or grit to get stuck in the gap too.

Who knows, eh? I expect a reputable supplier will replace/swap if you are unhappy.

The dents do look merely cosmetic. But the duff driver is clearly doing something bad. A full frequency response without filter might tell you more.

You've got Michael Chua's measurements to compare:

Swift 2.5 (Zaph ZA14W08 with Peerless DQ25SC16-04) – AmpsLab

1.5kHz is the region where surrounds and corrugated spiders cause distortion. Maybe too much glue? Maybe a rubbing voicecoil.

Rubbing voicecoils are usually easy to feel with a bit of prodding and pushing. The cure is often to rotate the driver. Not unknown for a bit of ferrite or grit to get stuck in the gap too.

Who knows, eh? I expect a reputable supplier will replace/swap if you are unhappy.

Back in the day, de Havilland unveiled the terrifically shiny de Havilland Comet Aeroplane. Unfortunately, "Widowmaker" might have been a better name.

The wings fell off after a few flights. This was not good. We started to understand metal-fatigue.

Actually, to be pedantic (me? never), the most famous issue was a result of over-stressing via regular pressurisation / depressurisation, causing fatigue around the punch-rivets around the supports & corners of the sharp, square-cut ADF window in the cabin roof and a general explosive decompression. In [George] Yoke Peter a window struck the elevators, likely causing severe uncontrolled pitch, tearing off the rear of the fuselage, with finally the wing structure, forward fuselage and fuel tanks failing. Not a nice subject, and my prayers are still with those who lost their lives, and their families. Ditto for 783, where the elevator spar was probably overstressed by a hard pull-up in bad weather, causing / followed by a wider structural failure.

These applied only to the Comet MkI, and the lessons learned from that (everything being new) fed into revised stress requirements, changes to construction requirements, and the subsequent models of the Comet and the Nimrod that was based upon it were very different aircraft. Sadly, commercially speaking, it was too late to save its reputation. And as you say, the early losses (not including unrelated accidents) provided through bitter experience an understanding that the stresses in large jets were higher than had been originally anticipated, with metal fatigue being a critical component. No more rivets of that kind in places like that, no more sharp cutouts, higher stress requirements &c. all came from it.

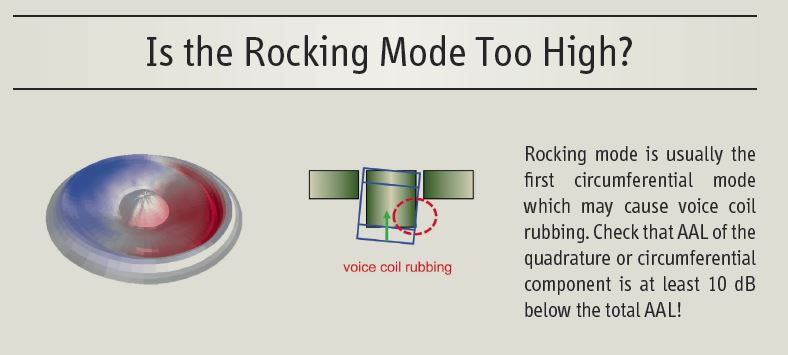

Be that as it may, re the driver, if the VC has sagged fractionally & is rubbing because the driver has been mounted the same way up for a long time (it does occur), as Steve suggests, try turning it 180 degrees. It may prevent rubbing etc. Worth a shot, since it costs nothing.

Last edited:

That was very interesting, Scottmoose! You can never discount the unexpected in engineering. Called "The Law of Unexpected Consequences" back in my day.

Long story short: The office manager decided to install water-saving throttle devices on our Urinals. Saved money. What could go wrong? Everything! All the flippin' toilets started horribly overflowing during the night! Turns out Uric acid crystals were building up and blocking them!

My favourite (exciting) engineering book is about Operation Black Buck.

Nothing to do with speakers, but engineering. The main trick was to thieve refuelling nozzles from Vulcans in our US cousin's museums... we'd run out of them in Dear Old Blighty, and the museum security guards had been given the night off...

Scottmoose has answered it, though I often try 90 degrees as a start. Theory is speakers sag a bit with age, and rub voicecoil occasionally. Especially if tolerances or manufacture is poor.

What else might go wrong here?

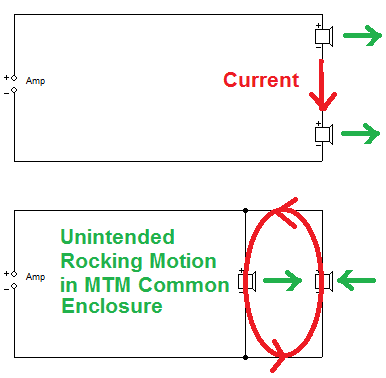

Rocking mode?

Another sort of rocking mode? I prefer series wiring.

General cone breakup issues:

I never like the sort of tank notch that Zaph and Paul Carmody use. A simple capacitor across the bass coil. Zaph|Audio - ZA5 Speaker Designs with ZA14W08 woofer and Vifa DQ25SC16-04 tweeter

I prefer an LCR as used by SEAS in the Thor: THOR

Tank notches break up badly at high volume, IMO. Sounds horrible. See, breakup is highly non-linear.

Michael Chua uses the same Zaph ZA5 drivers. It might be a better circuit, but I really haven't seen it yet: Swift 2.5 (Zaph ZA14W08 with Peerless DQ25SC16-04) – AmpsLab

My longest post ever! Keep you entertained in lockdown I hope.

Long story short: The office manager decided to install water-saving throttle devices on our Urinals. Saved money. What could go wrong? Everything! All the flippin' toilets started horribly overflowing during the night! Turns out Uric acid crystals were building up and blocking them!

My favourite (exciting) engineering book is about Operation Black Buck.

Rowland White in "Vulcan 607" said:Synopsis

It was to be one of the most ambitious operations since 617 Squadron bounced their revolutionary bombs into the dams of the Ruhr Valley in 1943...When Argentine forces invaded the Falklands in the early hours of 2 April 1982, Britain's military chiefs were faced with a real-life Mission Impossible. Its opening shot, they decided, would be Operation Black Buck: to strike a body blow at the occupying army, and make them realize that nothing was safe - not even Buenos Aires...

The idea was simple: to destroy the vital landing strip at Port Stanley. The reality was more complicated. The only aircraft that could possibly do the job was three months from being scrapped, and the distance it had to travel was four thousand miles beyond its maximum range. It would take fifteen Victor tankers and seventeen separate in-flight refuellings to get one Avro Vulcan B2 over the target, and give its crew any chance of coming back alive. Yet less than a month later, a formation of elderly British jets was launched from a remote island aribase to carry out the longest-range air attack in history.

At the tip of the spear was a single aircraft, six men, and twenty-one thousand-pound bombs, facing a hornet's nest of modern weaponry: the radar-guided guns and missiles of the Argentine defences. There would be no second chances...It was the end of an era - the last time the RAF flew heavy bombers into combat before they were replaced by their digital, fly-by-wire, laser-guided successors.

There were many who believed it couldn't be done. Drawing on extensive interviews with the combatants, Falklands residents and British High Command, and with unprecedented access to comtemporary military records, Rowland White takes us, for the first time, to the beating heart of the legendary raid. "Vulcan 607" is a story of ingenuity, courage and sheer bloody-mindedness that's destined to become a classic.

Nothing to do with speakers, but engineering. The main trick was to thieve refuelling nozzles from Vulcans in our US cousin's museums... we'd run out of them in Dear Old Blighty, and the museum security guards had been given the night off...

Its the Zaph ZA5. I purchased it from Madisound 2 years ago. I am not sure they’ll change it for me now. What so you mean rotate the driver?

Scottmoose has answered it, though I often try 90 degrees as a start. Theory is speakers sag a bit with age, and rub voicecoil occasionally. Especially if tolerances or manufacture is poor.

What else might go wrong here?

Rocking mode?

Another sort of rocking mode? I prefer series wiring.

General cone breakup issues:

I never like the sort of tank notch that Zaph and Paul Carmody use. A simple capacitor across the bass coil. Zaph|Audio - ZA5 Speaker Designs with ZA14W08 woofer and Vifa DQ25SC16-04 tweeter

I prefer an LCR as used by SEAS in the Thor: THOR

Tank notches break up badly at high volume, IMO. Sounds horrible. See, breakup is highly non-linear.

Michael Chua uses the same Zaph ZA5 drivers. It might be a better circuit, but I really haven't seen it yet: Swift 2.5 (Zaph ZA14W08 with Peerless DQ25SC16-04) – AmpsLab

My longest post ever! Keep you entertained in lockdown I hope.

There you go. Good illustration of what can happen.

Ah, Black Buck. How they pulled that one off was -'impressive'. Still more that they got authorisation for it.

Still more that they got authorisation for it.

Re breakup, is it the tank notch itself Steve, or is it the fact that the filter no longer has a monotonic or similarly progressive rolloff? I find variations useful, but you need to be careful to ensure you don't end up with insufficient suppression above / below the zero pole frequency. Depends on the driver's response & your crossover frequency in relation to whatever you're stamping on.

Equally, a simple notch (bottomless or otherwise) may not adequately deal with cone resonant amplification in the passband -you can take out, say, a midbass driver's main cone mode, but the HD products lower down are still present, & the harder you crank it, the more likely it is you'll hear it. Depends on the baseline distortion performance of the driver of course -if it's low enough in the first place, may not be a problem. Rare for that to be the case though, which is one reason I tend to like low XO frequencies providing the tweeter can handle it at the desired limits.

However. Sorry about the OT!

Ah, Black Buck. How they pulled that one off was -'impressive'.

Re breakup, is it the tank notch itself Steve, or is it the fact that the filter no longer has a monotonic or similarly progressive rolloff? I find variations useful, but you need to be careful to ensure you don't end up with insufficient suppression above / below the zero pole frequency. Depends on the driver's response & your crossover frequency in relation to whatever you're stamping on.

Equally, a simple notch (bottomless or otherwise) may not adequately deal with cone resonant amplification in the passband -you can take out, say, a midbass driver's main cone mode, but the HD products lower down are still present, & the harder you crank it, the more likely it is you'll hear it. Depends on the baseline distortion performance of the driver of course -if it's low enough in the first place, may not be a problem. Rare for that to be the case though, which is one reason I tend to like low XO frequencies providing the tweeter can handle it at the desired limits.

However. Sorry about the OT!

What is this? Is this glue sticking out or what? this is about the only thing I could find abnormal. The VC is not rubbing or anything I checked. And I can't exactly figure out how to "rotate" the driver. Sorry I am pretty much a newbie if you all haven't figured already.

Attachments

Yes, looks like magnet glue. Nothing to worry about there.

By rotating the driver we mean mounting it back on the enclosure so that it is upside down compared to the way it was mounted previously.

Yes. I have done that! Took it out, mounted it back in the enclosure in a different way.

Is it possible too much glue is causing this issue as mentioned by Steve earlier?

Maybe too much glue?

I think Steve mentioned glue in relation to it preventing the free movement of the front suspension (the roll surround) or the rear suspension (the corrugated 'spider').

I don't know if it is possible that magnet glue has got into the narrow magnet gap that the voice coil vibrates within. If it is possible, there would be no way of telling without destructive dismantling of the driver.

I don't know if it is possible that magnet glue has got into the narrow magnet gap that the voice coil vibrates within. If it is possible, there would be no way of telling without destructive dismantling of the driver.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Cone has a small dent/scratch. Audible?