Well here's some info on my newest project. (Skhorn is pronounced like the word scorn.)

In short this's something I've been working on for years to replace my Othorn cabs. The design goals going in were pretty much the same. PA or very high level music playback in large or outdoor spaces. The main areas that I wanted to improve over the Othorn are as below.

#1 Cut down on cabinet and panel vibration near the driver.

#2 Improve the fold or reduce build complexity.

#3 Higher overall performance.

#4 More driver options and some less expensive ones.

#5 Increase the “FUN” factor even further

After simulations of what seemed like every cab type and most of the commonly available drivers, I ended up ditching the 8th order BP I had, which looked really good on paper, but was an absolute nightmare to turn from a sim into a buildable cab. Not to mention the extreme sensitivity to mistuning, etc... After that a TH was going to be the follow up and I had it all drawn up but I just wasn't satisfied with it as it seemed like an incremental step rather than something new. Finally I settled on the cab type also used on the M.A.U.L.. It was basically a parallel effort on both designs. The big one just happened to get built and tested first.

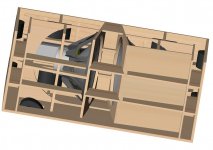

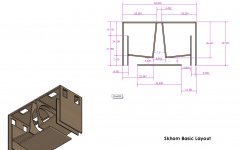

The Skhorn is a 24x32x54" cab that is comparable in size to the low tuned dual 18 vented cabs on the market. It's 24cu ft or 680L external volume. Originally I wanted to keep the size the same as the Othorn which is 18cu ft external but using 2 large drivers simply required a bit more volume and a different shape. The Skhorn is exactly 33.33% bigger than the Othorn, so 3 Skhorn are the same volume of space as 4 Othorn cabs.

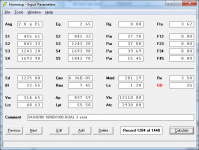

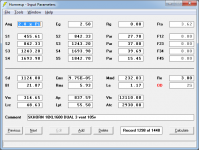

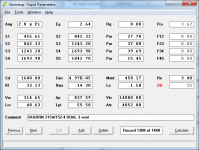

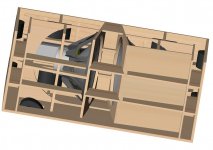

I settled on a quasi 6th order BP, where the low end is vented and the upper end of the loading is a short, expanding slot/horn, with an opposed pair of 15-21" drivers, in an OD arrangement. I ended up at this while trying to work on translating a standard 6th order sim into wood and screws. I was having trouble getting the upper bass vents to fit into the cabinet and this caused me to look at how a straight slot performed instead since it is MUCH simpler to fit into the cab design. From there it was natural to model the slot with both a positive and negative taper and see what happened. A positive flare seemed to offer some improvements over a simple vent and with tweaking of the length, area and expansion, I found that this type of loading for the drivers could produce a smooth response over a wide bandwidth while also exhibiting some gains over a standard vented system using the same driver.

EDIT: 02/20/18

I have improved the accuracy of HR simulation inputs when compared to the measured ground-plane performance of the final speaker. The HR inputs below are not nearly as accurate as those developed after testing the final cab.

Here’s the cab design.

In short this's something I've been working on for years to replace my Othorn cabs. The design goals going in were pretty much the same. PA or very high level music playback in large or outdoor spaces. The main areas that I wanted to improve over the Othorn are as below.

#1 Cut down on cabinet and panel vibration near the driver.

#2 Improve the fold or reduce build complexity.

#3 Higher overall performance.

#4 More driver options and some less expensive ones.

#5 Increase the “FUN” factor even further

After simulations of what seemed like every cab type and most of the commonly available drivers, I ended up ditching the 8th order BP I had, which looked really good on paper, but was an absolute nightmare to turn from a sim into a buildable cab. Not to mention the extreme sensitivity to mistuning, etc... After that a TH was going to be the follow up and I had it all drawn up but I just wasn't satisfied with it as it seemed like an incremental step rather than something new. Finally I settled on the cab type also used on the M.A.U.L.. It was basically a parallel effort on both designs. The big one just happened to get built and tested first.

The Skhorn is a 24x32x54" cab that is comparable in size to the low tuned dual 18 vented cabs on the market. It's 24cu ft or 680L external volume. Originally I wanted to keep the size the same as the Othorn which is 18cu ft external but using 2 large drivers simply required a bit more volume and a different shape. The Skhorn is exactly 33.33% bigger than the Othorn, so 3 Skhorn are the same volume of space as 4 Othorn cabs.

I settled on a quasi 6th order BP, where the low end is vented and the upper end of the loading is a short, expanding slot/horn, with an opposed pair of 15-21" drivers, in an OD arrangement. I ended up at this while trying to work on translating a standard 6th order sim into wood and screws. I was having trouble getting the upper bass vents to fit into the cabinet and this caused me to look at how a straight slot performed instead since it is MUCH simpler to fit into the cab design. From there it was natural to model the slot with both a positive and negative taper and see what happened. A positive flare seemed to offer some improvements over a simple vent and with tweaking of the length, area and expansion, I found that this type of loading for the drivers could produce a smooth response over a wide bandwidth while also exhibiting some gains over a standard vented system using the same driver.

EDIT: 02/20/18

I have improved the accuracy of HR simulation inputs when compared to the measured ground-plane performance of the final speaker. The HR inputs below are not nearly as accurate as those developed after testing the final cab.

Here’s the cab design.

Attachments

Last edited:

@ Josh Ricci

Interesting project !

I've stayed away from 6th etc orders, due to Lots of people on forums saying they didn't sound good. Plus i've heard quite a number of "pro" ones over the years that sound one note & tiresome ! I realise that the T/S & box build is more critical with these designs, so it "might" be due to mismatches ?

Anyway, i'm looking forward to seeing how this build matches the sims etc when tested

Interesting project !

I've stayed away from 6th etc orders, due to Lots of people on forums saying they didn't sound good. Plus i've heard quite a number of "pro" ones over the years that sound one note & tiresome ! I realise that the T/S & box build is more critical with these designs, so it "might" be due to mismatches ?

Anyway, i'm looking forward to seeing how this build matches the sims etc when tested

@Zero D. that is exactly my expience. It's is a bit better than front-loaded subs which most of the time sounds 'one-note' and over compensating in upper distortion. (depending on the sound guy)

I have worked with a couple of bandpas subs. They do sound less 'one-noted' as front loaded subs. But delivering 'articulated' bass notes like sub horns they did not.

But who knows! Its a sort of hybrid horn, so maybe its sound better from 40-100 and more one note from 20-40. (speculating here)

I have worked with a couple of bandpas subs. They do sound less 'one-noted' as front loaded subs. But delivering 'articulated' bass notes like sub horns they did not.

But who knows! Its a sort of hybrid horn, so maybe its sound better from 40-100 and more one note from 20-40. (speculating here)

USRFobiwan

maybe its sound better from 40-100 and more one note from 20-40

Well i'm hoping it's the other way round

About the handle placement...The way the cab is internally things are a bit tight. I placed the handles where I would like them to be and they would fit. It will be fine for me. I have a lot of experience moving cabs that are large and heavy and these will be no problem for me. You shouldn't be using handles on subs like this to deadlift and carry them long distances. They are there for pushing, pulling, turning, flipping, tilting etc. if the cab must be physically carried by 2 people the handles on the ends will allow this easily. Estimated weight is around 240lbs with a pair of 40lb drivers and I think that may be over estimated a bit. I'll have to measure one. I always use dollies or other sets of wheels for moving things like this though and I'd assume most others do as well. Who is dead-lifting and carrying their subs around? None of the people I work with certainly. Handle type, placement, skid plates or corner wheels could be added to taste. I won't have any trouble tilting these up and on to a dolly and getting them into a van or truck by myself.

Hi Josh Ricci,

Nice work. Looks like a complex construction though.

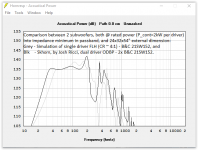

It's interesting to compare the Skhorn to a FLH (front loaded horn) of the same size. I sketched out a single driver FLH w/ CR ~ 4:1 (compression ratio) in the same box size, and used Hornresp to compare the SPLs @ rated power (2kW per driver) into impedance minimum in the passband. The Skhorn clearly has ~ 10Hz more low frequence extension in the same box size.

Do you have measurements of the SKhorn(s)?

Regards,

Nice work. Looks like a complex construction though.

It's interesting to compare the Skhorn to a FLH (front loaded horn) of the same size. I sketched out a single driver FLH w/ CR ~ 4:1 (compression ratio) in the same box size, and used Hornresp to compare the SPLs @ rated power (2kW per driver) into impedance minimum in the passband. The Skhorn clearly has ~ 10Hz more low frequence extension in the same box size.

Do you have measurements of the SKhorn(s)?

Regards,

Attachments

I did do plenty of simulating with FLH's and also TH, BLH, scoops, BP4, BP6, BP8, vented, etc...You name it and I probably spent a good deal of time simulating what could be done within the defined parameters. This appeared to offer the best set of compromises and potentially the highest performance from a cab of this size with the amount of extension needed. I always have very specific goals for the size and extension of my cabs. FLH just never seems to be the best option for my goals. It either does not extend low enough, needs to be too large, doesn't offer enough headroom potential, or the folding becomes problematic and too complicated.

As far as sound quality goes that is yet to be determined but I am quite confident these are going to be far from what people think of as a BP sound. I've also heard many, many BP cabs both 4th and 6th order that sounded bad. Some of the first subs I heard were absolutely horrible car audio BP's back when I was a teen. One note output and overhang for days. I've also heard just about every other type of cabinet at one point or another as well and I've heard bad examples and good examples of all of those as well. TH's for example can sound excellent but a great many of them sound extremely colored to me due to the spike near the 5th harmonic and the rough response above that point. Those typically ring like hell too. It can be damped and controlled somewhat through good design but often isn't. They sound extremely good over a narrow range below the typical response spike but that's a quite limited bandwidth. Some of the TH's I've heard had serious issues covering the full bass bandwidth if they were tuned too low. The best sounding TH's I've heard are the DSL TH115-118 and the Othorn. The gulf in coloration between these and some of the worst TH's I've heard is huge. Those TH's are pretty well damped and the nastiness in the response are pushed up above the low pass filter region which helps immensely. I've also heard some bad FLH's with ragged response shapes, ringing and colorations so I don't buy into them automatically either. Some of them are very good though. It really comes down to the particular design with any type of cabinet. There are bad and good examples of each. There's certainly nothing in the simulations that says these will sound bad or one note compared to any of the other designs typically used for pro audio. I'll be GP testing these extensively this summer and also doing a lot of listening so that will tell the final story.

As far as sound quality goes that is yet to be determined but I am quite confident these are going to be far from what people think of as a BP sound. I've also heard many, many BP cabs both 4th and 6th order that sounded bad. Some of the first subs I heard were absolutely horrible car audio BP's back when I was a teen. One note output and overhang for days. I've also heard just about every other type of cabinet at one point or another as well and I've heard bad examples and good examples of all of those as well. TH's for example can sound excellent but a great many of them sound extremely colored to me due to the spike near the 5th harmonic and the rough response above that point. Those typically ring like hell too. It can be damped and controlled somewhat through good design but often isn't. They sound extremely good over a narrow range below the typical response spike but that's a quite limited bandwidth. Some of the TH's I've heard had serious issues covering the full bass bandwidth if they were tuned too low. The best sounding TH's I've heard are the DSL TH115-118 and the Othorn. The gulf in coloration between these and some of the worst TH's I've heard is huge. Those TH's are pretty well damped and the nastiness in the response are pushed up above the low pass filter region which helps immensely. I've also heard some bad FLH's with ragged response shapes, ringing and colorations so I don't buy into them automatically either. Some of them are very good though. It really comes down to the particular design with any type of cabinet. There are bad and good examples of each. There's certainly nothing in the simulations that says these will sound bad or one note compared to any of the other designs typically used for pro audio. I'll be GP testing these extensively this summer and also doing a lot of listening so that will tell the final story.

Hi Josh Ricci,

Nice work. Looks like a complex construction though.

It's interesting to compare the Skhorn to a FLH (front loaded horn) of the same size. I sketched out a single driver FLH w/ CR ~ 4:1 (compression ratio) in the same box size, and used Hornresp to compare the SPLs @ rated power (2kW per driver) into impedance minimum in the passband. The Skhorn clearly has ~ 10Hz more low frequence extension in the same box size.

Do you have measurements of the SKhorn(s)?

Regards,

That sounds about right. Full GP workup at DB will be coming in the 2nd quarter of this year. We'll see where the rubber meets the road. I expect some slight differences from the simple HR model just due to driver inductance, parameter variances and lowered vent tuning, etc. I'll tweak the HR model to be more accurate after I have the full measurements as per usual. I'll be using 21ipals in mine and I also have a pair of 21ds115's on hand that I'll be testing in one of these too.

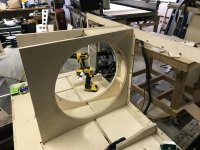

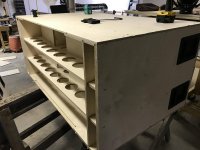

Construction isn't bad. It looks a lot worse than it is. It's mostly bracing and hatch placement. The simplified plan is this. This is the critical stuff. Everything else can be modified to suit the tools on hand or to taste. Bracing, hatches, driver cutouts, handles, hardware, etc...All of that is adjustable really.

+1TH's for example can sound excellent but a great many of them sound extremely colored to me due to the spike near the 5th harmonic and the rough response above that point. Those typically ring like hell too. It can be damped and controlled somewhat through good design but often isn't. They sound extremely good over a narrow range below the typical response spike but that's a quite limited bandwidth.

Hi Josh,

Neat design. For the IPAL powered cabinet, you may want to put the pressure sensor in a tube that connects to both sides of the throat.

Hmmm...Got a quick sketch of what you're thinking?

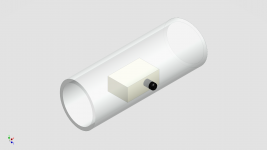

The DSP wants to see the pressure at the back and front of the cones to keep things from getting out of hand. It looks like 1.5" PVC should work.Hmmm...Got a quick sketch of what you're thinking?

Attachments

Last edited:

Yeah 4 to 1 on paper.

Dan that might work. Have to seal the crap out of it though. Air leak through the pvc would be not good.

Getting a 1.5" hole that's cut at 6 degree angle and lines up with the other side perfectly now that's been assembled would be interesting. Could have done it pretty easily before I put it together. Could seal it up with a bunch of PL fairly easily though. Not sure about sealing the ipal sensor inside the PVC with the curve.

Is there a reason you need to measure pressure for both drivers? Wouldn't each side be identical?

Last edited:

I'm not entirely sure about that really. The literature imply that the sensor placement and polarity are crucial or instability will result. I would think that as long as the drivers are operating in phase into a common throat that the dpc sensor could be placed normally. However the drivers are mounted face to face and 180deg out mechanically. I've attempted to ask PS about sensor placement and operation with throat chambers and multiple driver arrangements but they ignored every question I've ever sent them. Unless you are an engineer with a huge customer for them, good luck getting any detailed information. Either that or they simply don't have the answers.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Ricci's Skhorn Subwoofer