> such as can crusher, magnetizer, blowing wires with current and spot welder?

Standard E-caps aren't very good for the applications you mentioned: they will do it a few times (or a few dozen times), and then weaken.

E-caps contain a ghost dead-ringer inside, the one that is activated for BP or non-polar caps.

Extreme discharge currents cause non-linear effects, allowing the ghost cap to reach finite values (it is normally ~∞ and very low voltage).This degrades the regular cap, rendering it weak and useless.

Capacitors designed for photo-flash applications have a special construction and withstand those conditions better.

In a magnetizer, if the conditions are well controlled, it is probably possible without reducing the life excessively, but other applications call for special, high pulse current caps.

Even a general-purpose film or PIO cap wouldn't last very long in such duties.

There are certainly possible uses for these caps, and I also have a number of them, bought from surplus stores or salvaged, and I sometimes have an application for them; not often, they mostly gather dust on a shelf, but they seem to have an infinite life, and I am happy to have them handy when I need them

Standard E-caps aren't very good for the applications you mentioned: they will do it a few times (or a few dozen times), and then weaken.

E-caps contain a ghost dead-ringer inside, the one that is activated for BP or non-polar caps.

Extreme discharge currents cause non-linear effects, allowing the ghost cap to reach finite values (it is normally ~∞ and very low voltage).This degrades the regular cap, rendering it weak and useless.

Capacitors designed for photo-flash applications have a special construction and withstand those conditions better.

In a magnetizer, if the conditions are well controlled, it is probably possible without reducing the life excessively, but other applications call for special, high pulse current caps.

Even a general-purpose film or PIO cap wouldn't last very long in such duties.

There are certainly possible uses for these caps, and I also have a number of them, bought from surplus stores or salvaged, and I sometimes have an application for them; not often, they mostly gather dust on a shelf, but they seem to have an infinite life, and I am happy to have them handy when I need them

An application example (the latest IIRC): I upgraded my conventional pillar-drill with a home-brew VFD designed for two-phase motors.

It required a rectifier/filter combo capable of converting the 230VAC into ~300VDC for the power bridges, and good HV caps were required.

The ones I used were >50 years old, but they still work beautifully, and I am using that drill a few times a week without problem, and without having to change the pulley/belt setting: it is permanently set at the lowest mechanical speed, but the VFD allows over-speeds as well as extremely low speeds, meaning I just need to adjust a potentiometer when I change the tool.

You do not need this kind of cap every month or even every year, but when you remember that they sit in your basement, ready for any application, they can be extremely useful.

You just need to remember that they exist, ready for the task you invent for them...

It required a rectifier/filter combo capable of converting the 230VAC into ~300VDC for the power bridges, and good HV caps were required.

The ones I used were >50 years old, but they still work beautifully, and I am using that drill a few times a week without problem, and without having to change the pulley/belt setting: it is permanently set at the lowest mechanical speed, but the VFD allows over-speeds as well as extremely low speeds, meaning I just need to adjust a potentiometer when I change the tool.

You do not need this kind of cap every month or even every year, but when you remember that they sit in your basement, ready for any application, they can be extremely useful.

You just need to remember that they exist, ready for the task you invent for them...

You can find one or more capacitors of this size in high power (tens of kW to MW size) inverters and frequency converters. But you are probably not going to build such a device. The capacitor is the cheaper part in such a device! For smaller converters in kW range you don't even need this size capacitors.

Would they work for filter caps in an HV supply?

That is what they are built and used for.

Would they work for filter caps in an HV supply?

You could use them in a OTL tube amp with solid state rectification.

I was looking at an OTL RC filter with ~6300uF at one point. Given the 240V mains input around there (and up to 253V is possible), a 400V would work but having 450V would give a little more margin. Add inrush limiting and away you go.

Audio is odds and ends use.

Very normal in HVAC systems, motor starters, AC filters, large SMPS, as run capacitors in single phase motors...

Also in power factor correction units, where capacitor banks are switched in and out to maintain the power factor, as required by the local power company.

Very normal in HVAC systems, motor starters, AC filters, large SMPS, as run capacitors in single phase motors...

Also in power factor correction units, where capacitor banks are switched in and out to maintain the power factor, as required by the local power company.

Power factor correction uses a lot less uF, at a lot more voltage. These are even too “big” for motor caps. For really *big* switch mode supplies, inverters, UPS systems, mostly. Anything where you need to rectify the mains directly to make a DC bus and draw dozens of amps.

Yes, they are typically in frequency converters and inverters. In my youth during studies I worked at a factory line and assembled frequency converters in the size a few kW to up to hundreds of kW. I think the largest were in MW size at the factory.

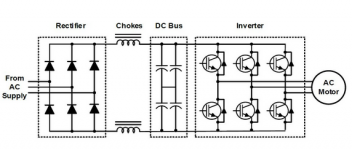

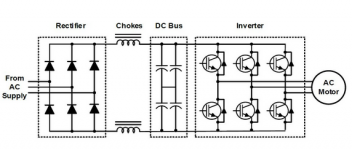

This is a typical layout of a frequency converter (googled):

Typical three phase rectifier for DC:

Chokes are big, couldn't find any picture of them.

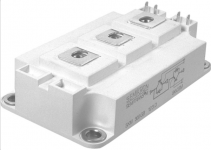

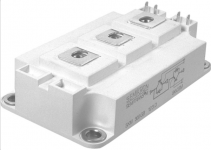

Typical IGBT transistor in the inverter side:

There are two transistors typically in each of these "bricks". So there are three modules in a 3-phase drive. This model is specified for 1200 V and 200 A. Note that these types of transistors can't be used for DC. Well, I do use one in a DC load that I built, but the load takes only about 10 A. I think it could work fine up to a few tens of amps, but IGBTs will break down due to hot spots in linear use, so I don't want to test (and impossible to predict). SOA isn't specified and data sheets specifically mentions that they are not for linear use.

I also built test stations at the factory for the units and sometimes when a component failed you heard a large bang from the other side of the factory. If you were to stand nearby the test station you definitely jumped. With the current involved the released energy is enormous. But the components are rugged and even if one of the transistors failed in the IGBT module, the other worked fine (I have a few souvenirs of these). And capacitors could have black soot marks all around but worked when tested (of course they were still scrapped and not reused). I have a box of such specimens and they work just fine.

This is a typical layout of a frequency converter (googled):

Typical three phase rectifier for DC:

Chokes are big, couldn't find any picture of them.

Typical IGBT transistor in the inverter side:

There are two transistors typically in each of these "bricks". So there are three modules in a 3-phase drive. This model is specified for 1200 V and 200 A. Note that these types of transistors can't be used for DC. Well, I do use one in a DC load that I built, but the load takes only about 10 A. I think it could work fine up to a few tens of amps, but IGBTs will break down due to hot spots in linear use, so I don't want to test (and impossible to predict). SOA isn't specified and data sheets specifically mentions that they are not for linear use.

I also built test stations at the factory for the units and sometimes when a component failed you heard a large bang from the other side of the factory. If you were to stand nearby the test station you definitely jumped. With the current involved the released energy is enormous. But the components are rugged and even if one of the transistors failed in the IGBT module, the other worked fine (I have a few souvenirs of these). And capacitors could have black soot marks all around but worked when tested (of course they were still scrapped and not reused). I have a box of such specimens and they work just fine.

- Home

- Amplifiers

- Power Supplies

- HV Electrolytic industrial caps - other uses than audio?