I was reading some stuff that seemed to indicate that the center bolt holding a transformer down should be insulated from the chassis, or better yet, not be conductive in the first place. Is this right? Or, is it important? I’ll be mounting the transformer on the steel bottom plate of the case, with the included rubber washer/pad.

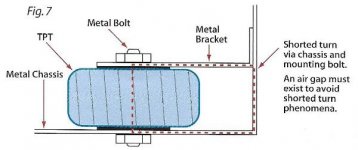

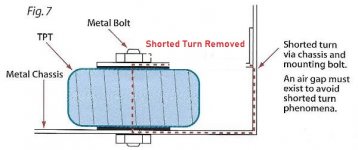

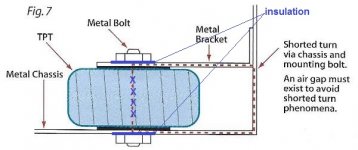

A steel bolt without insulation is OK if there is no outer can or other path from the top of the bolt to ground. If a metal outer can is placed over the toroid, and it is not insulated where it contacts the chassis, then the bolt through the center must be non conductive or insulated.

You must avoid creating a complete turn through the transformer that is shorted, as this "shorted turn" is the same as a one turn winding on the transformer with its output shorted.

You must avoid creating a complete turn through the transformer that is shorted, as this "shorted turn" is the same as a one turn winding on the transformer with its output shorted.

I was reading some stuff that seemed to indicate that the center bolt holding a transformer down should be insulated from the chassis, or better yet, not be conductive in the first place. Is this right? Or, is it important? I’ll be mounting the transformer on the steel bottom plate of the case, with the included rubber washer/pad.

If you mount a toroidal in a slim-line chassis its wise to insulate the part of the case than could touch the top of the toroid if the case were accidentally compressed/dented at that point - or put a plastic cap on the mounting bolt to avoid the possilbity of a short (which would spot-weld itself otherwise).

A steel bolt without insulation is OK if there is no outer can or other path from the top of the bolt to ground. If a metal outer can is placed over the toroid, and it is not insulated where it contacts the chassis, then the bolt through the center must be non conductive or insulated.

You must avoid creating a complete turn through the transformer that is shorted, as this "shorted turn" is the same as a one turn winding on the transformer with its output shorted.

I assume this doesn't apply if the mounting bolt doesn't touch the cover? Like this style that mounts to chassis in the corners?

Attachments

It would have run for just a couple of seconds and blown a fuse.

In this function it's only a shield, and part of the chassis.

This demo is pretty cool.

Shorted turn on transformator - YouTube

In this function it's only a shield, and part of the chassis.

This demo is pretty cool.

Shorted turn on transformator - YouTube

Last edited:

I assume this doesn't apply if the mounting bolt doesn't touch the cover? Like this style that mounts to chassis in the corners?

Where can you get a cover like this?

I've seen them on ebay, aliexpress etc, but getting the correct size may be a problem.

105*51mm +-0.5 Metal Shield Toroid Transformer Cover box Protect Chassis Case[C1] | eBay

1p 140x65mm Black Metal Shield box Toroid Transformer Cover Protect Chassis case | eBay

105*51mm +-0.5 Metal Shield Toroid Transformer Cover box Protect Chassis Case[C1] | eBay

1p 140x65mm Black Metal Shield box Toroid Transformer Cover Protect Chassis case | eBay

Where can you get a cover like this?

Knock yourself out : Cover For Toroidal Transformer - Consumer Electronics - AliExpress

You could put a toroid in one of those.

Again, if you mount the toroid in the normal manner with a bolt to the chassis below, then put this cover over it you must avoid the top of the bolt touching the inside of the cover.

Where can you get a cover like this?

I get mine from GD-Parts.

Wholesale Buy Various Tube Guitar Amp DIY Repair Parts from mafaudio Vintage HIFI DIY

I did not know stainless is usually non-ferromagnetic... I've been using brass hardware wherever I want that property, but stainless is easier to find.

Right now I'm doing something like knauf's picture. It's insulated at the top and bottom with washers, but I can't guarantee it won't **** to one side and short to the chassis, as I don't have a grommet on it.

I'll have to find a big nylon bolt somewhere. No where local stocks anything that big.

Right now I'm doing something like knauf's picture. It's insulated at the top and bottom with washers, but I can't guarantee it won't **** to one side and short to the chassis, as I don't have a grommet on it.

I'll have to find a big nylon bolt somewhere. No where local stocks anything that big.

- Home

- Amplifiers

- Power Supplies

- Do I need to insulate the center bolt securing a toroidal transformer?