Don't use ceramics, the have too low impedance and may cause oscillation together with electrolytics.

No. You cannot have oscillations in this type of power supply.

You can only have oscillations in regulated power supplies with a feedback mechanism.

Film caps at the output of regulators can, in some cases, cause oscillations. Electrolytics are the best choice on the output of regulators.

Jan

Just wanted to ask about this statement, i am getting a distinct loss of treble, is there any way the cap's frequency impedance can be changed ie by changing the cap's make or capacitance value to avoid this treble eq'ing.

If you do a bode plot (or model in ltpice and do a bode plot) it will show you the effect. I bumped into this looking at fast switching for the tube-direct-digital amp design (high frequency).

Output of one stage and input into the next is important.

The output - in terms of resistance (both Rp and Ra) and the capacitance (both signal cap and the miller capacitance of the grid of the receiving tube) play a part. However there's also impedance, capacitance and inductance in every component - such as caps, wires, sockets etc.

The result is a low pass filter. One that when used correctly means you can 'abuse' Miller capacitance for good (ie using grid stop resistors).

In a design I have three 'identical' PP 0.1uF caps in parallel between stages. The result is 0.3uF but a reduction in resistance from the caps and less of a low pass filter effect given it's need to support higher frequencies.

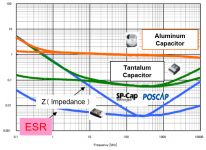

Now adding different caps in parallel - such as electrolytic and PPs etc means you get different frequency impedances, thus you end up almost running LPFs in parallel.

Stolen from the Panasonic website:

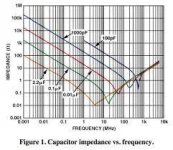

Now just looking at one type but different capacitances:

Now imagine combining by adding two of those lines together - that's what happens when you bypass. Your frequency response will then vary depending on each of the caps you have in bypass.

It's important, if you want to build in some LPF, to know the impedance and capacitances. Ultimately these the influence the frequency response. Possibly consider using parallel caps where needed - this then applies the parallel impedance and parallel capacitance rules accordingly.

Last edited:

Thanks!

What is the answer. What value caps should i be using. The 0.1uf caps will support higher frequencies but probably beyond the 20khz of human hearing in a real life situation. I do not want to build a low pass filter quite the opposite as there is a lack of treble already. I have film caps from small values of 1uf up to 100uf.

What is the answer. What value caps should i be using. The 0.1uf caps will support higher frequencies but probably beyond the 20khz of human hearing in a real life situation. I do not want to build a low pass filter quite the opposite as there is a lack of treble already. I have film caps from small values of 1uf up to 100uf.

....I do not want to build a low pass filter quite the opposite as there is a lack of treble already.....

So you want to hear more treble from the wall outlet?

Low-passing the power is not the same as low-passing the signal.

There was a lot of noise coming through the speaker so i inserted another 47,000uf and the noise went down. I kept inserting caps, the noise kept lowering, until i reached 135,000 uf and the noise disappeared completly.

I figured 135,000 uf was the perfect value so i took out the six caps and replaced with a single 150,000uf cap which is the closest value i could find, but some of the noise came back.

It is very likely that the resistance before with the increased capacitance (and by putting in parallel) you're lowering the series resistance (ESR) so the supply can deliver more current faster.

Now electrolytics have a number of parameters:

* max current

* an ESR curve - with respect to frequency.

By adding caps in parallel you add the capacitance but the resistances (ESR) in parallel causes the total ESR to reduce. Essentially they become a lower impedance power supply (a good thing).

The net effect is that the amp can deliver more current faster. Additionally the caps don't heat up as much.

Replace with a single large cap.. then you have to look at the ESR and current ratings. It's likely that although comparing single 4700uF and 150,000uF caps, the 150,000uF caps are better on paper.. in reality the parallel smaller caps probably outclass it.

There's a reason that big amp manufacturers like current power supplies with large numbers of caps in parallel

In terms of noise - the lower ESR probably means the amp is getting current faster thus there's less voltage drop, less distortion and probably also true that 150,000uF cap is probably not as good to act like a LPF for the mains noise (would need to look at the ESR frequency graph).

As PRR has said - power and signal are two different but related things. My mistake for taking you through a little joyride.. I've been up to my eyes in cap specs recently.

Last edited:

I do appreciate the points, am still puzzled and will apppreciate clarification.

The esr of the single 150,000uf cap is 9milliohms. Assuming the esr for the six parallel caps is something similar. then the esr for the parallel configuration is something like 1.5 milliohms.

Will a difference of approximatly just 7.5 milliohms really make that much of a difference. Just a fraction of an ohm. I mean the amount of noise coming through with the single cap is much more than the paralleled caps, with the paralled caps the amp is silent so they are far more effective of that there is no doubt but are you sure it is just the esr that is causing this. Is there another explanations or other factors coming into play.

The esr of the single 150,000uf cap is 9milliohms. Assuming the esr for the six parallel caps is something similar. then the esr for the parallel configuration is something like 1.5 milliohms.

Will a difference of approximatly just 7.5 milliohms really make that much of a difference. Just a fraction of an ohm. I mean the amount of noise coming through with the single cap is much more than the paralleled caps, with the paralled caps the amp is silent so they are far more effective of that there is no doubt but are you sure it is just the esr that is causing this. Is there another explanations or other factors coming into play.

I do appreciate the points, am still puzzled and will apppreciate clarification.

The esr of the single 150,000uf cap is 9milliohms. Assuming the esr for the six parallel caps is something similar. then the esr for the parallel configuration is something like 1.5 milliohms.

Will a difference of approximatly just 7.5 milliohms really make that much of a difference. Just a fraction of an ohm. I mean the amount of noise coming through with the single cap is much more than the paralleled caps, with the paralled caps the amp is silent so they are far more effective of that there is no doubt but are you sure it is just the esr that is causing this. Is there another explanations or other factors coming into play.

Don't forget heat - the more heat the more noise typically. Heat also affects components around it (resistors etc). The paralleled caps has more surface area.

Lastly caps can and do have distortion and noise. So you can add harmonics to caps. Have a read here: Index of /images/pdf/Cyril_Bateman

Don't discount the net effect IF the there is voltage sag for switching. The drop in voltages can cause the operating points of components to shift causing more distortion. It's the reason why guitar amps often prefer valve rectifiers - they have saggy voltages on the B+ lines that then cause the operating points to shift giving a different (and preferred) distortions/harmonics plus the effect also softens transients resulting in the the less hard sound.

I can't really say if a difference of 7.5m would make that much of a difference. It depends on the design. However IF the impedance actually is that low (typically for low frequencies, which is what DC power is, the impedance isn't that low). The data sheet may be giving you a favourable higher frequency ESR.

For example - a poly cap may have 0.0048 at 10Khz but 0.4 at 100Hz. For electrolytics multiply that - some have 12ohms are 100Hz but 0.04 at 10Khz. The large the capacitance typically the less ESR as there's more plate surface. Also the constructions that favour thinner conductive elements to make more capacitance in the size results in lower current performance (and vice versa for the thicker elements).

Note that WIMA DC MKP4 caps - the 80uF cap is 3mOhm. So I suspect that the large electrolytic cap may not be giving the claimed ESR at the frequencies you want.

As a side note - testing caps (correctly) is complex. Often people use their ears and listen. No problem with that but it is surjective. The data sheets are often marketing's wet dreams where lack of information is just as misleading as the information on the sheet. The issue here is to solve your problem empirically and objectively would need you todo start down this path.

Last edited:

Just to further answer your question:

Class A/AB1/AB2 - 7.3m ESR difference isn't going to do much. Current and ripple stability - yes.

Class B - the switching on and off (ie 1/2 sine wave) isn't going todo much Current transient and stability - yes.

Class D - (actually any PWM/PDM switching) then yes ESR will typically make a large impact depending on the switch rates - and even more impact when coupled with the current demand. Current capability - yes. Voltage stability is important (for those that switch to specific voltages - ie PWM triangle wave to sine wave analogue conversion) and for those that use pure digital input with full rail-to-rail.

SMPS are essentially related to class D as they use switching (20Khz to 1Mhz) hence using the WIMA DC link example. On the other side of the 24V->390V booster that those sat in, I had a bank of seven low-ESR 330uF 50V electrolytics in parallel to provide the required low impedance to provide the current at the switching rate. A single cap of a larger capacitance with the 'low ESR' simply couldn't do that.

Class A/AB1/AB2 - 7.3m ESR difference isn't going to do much. Current and ripple stability - yes.

Class B - the switching on and off (ie 1/2 sine wave) isn't going todo much Current transient and stability - yes.

Class D - (actually any PWM/PDM switching) then yes ESR will typically make a large impact depending on the switch rates - and even more impact when coupled with the current demand. Current capability - yes. Voltage stability is important (for those that switch to specific voltages - ie PWM triangle wave to sine wave analogue conversion) and for those that use pure digital input with full rail-to-rail.

SMPS are essentially related to class D as they use switching (20Khz to 1Mhz) hence using the WIMA DC link example. On the other side of the 24V->390V booster that those sat in, I had a bank of seven low-ESR 330uF 50V electrolytics in parallel to provide the required low impedance to provide the current at the switching rate. A single cap of a larger capacitance with the 'low ESR' simply couldn't do that.

Last edited:

No. You cannot have oscillations in this type of power supply.

You can only have oscillations in regulated power supplies with a feedback mechanism.

Film caps at the output of regulators can, in some cases, cause oscillations. Electrolytics are the best choice on the output of regulators.

Jan

Excuse me for this side track, but I find this interesting. There is a lot of warnings around of the ceramic-electrolytic combination. I suppose the oscillations is caused by the switching that inserted energy at the resonance frequency for the capacitors.

- Home

- Amplifiers

- Power Supplies

- Is a single capacitor psu possible