Simply bring your transformers to a xtrm manufacturer.

Most Canadian transformers manufacturers uses Dolph Varnish.

Just noticed that Edcor is also using Dolph, cat. AC-43

Do you know if this is what Hammond uses on their small stuff? Looking at the part no. online it's an air dry conformal coating, as opposed to a VPI bake to dry coating. If that will do the job I need it to do, it definitely simplifies things. The price is decent too, and it's not so hard to find.

I'm in Alberta so if someone local does it, it will have to be either a motor rewind shop, or someone who works on large distribution size transformers. I decided to do it myself mostly because it's more fun this way, and also, I can be completely in control of the process, and only have myself to blame if there's a mistake.

Another vote for the varnish.

I just used some old regular varnish I had on the shelf. Leave the transformer to dry in the sun was all I did. Put the transformer in a zip lock bag, poured in the varnish, leave it sit for quite awhile, I think a couple of days in the sun so the warmth kept viscosity lower. Then take it out of the bag and leave it to dry in the sun for many days, maybe a week or more. Went from a buzzing monster to a quiet mouse.

Buzzing monster to quiet mouse is exactly what I'm after. Is that a filter choke?

when i was starting out 40 or so years go, i used to buy shellac flakes by the kilo from hardware supply stores, and plenty of denatured alcohol, the mixture is also good to use, all bio friendly?? i believe...

I could easily get this too, I really like shellac as a wood sealer, it's very easy to work with, and I like the orange tinge.

I used the proper air dry transformer varnish for years, but stopped using it on 2 counts:

1) if can loses a certain % of it solvents content through repeated use and evaporation, it triggers a gelling reaction and then you have to discard it.

2) to prevent that, every time you use it and before closing the can until next use you must add a little solvent.

Problem is proper solvent is Toluene, which has become a "controlled chemical" which is a p.i.t.a. : chemical suppliers only sell me 1 litre, tops, I have to show ID and sign for it, if I want more I have to register in a DEA controlled list and prove I actually need it, the works.

"Because it is used in drug manufacturing"

Funny thing is that when TV News show Police/DEA seizing "cocaine kitchens" in the middle of nowhere you can see lots of 200 liter/55 gallon drums full of the stuff ... WTF?

So the bad guys get all they want while real users who need it for Technical reasons must go through all the red tape ..... oh well ....

So I "downgraded" to standard wood varnish, whose solvent is cheap and not controlled, only have to wait a little more for it to dry.

No big deal.

1) if can loses a certain % of it solvents content through repeated use and evaporation, it triggers a gelling reaction and then you have to discard it.

2) to prevent that, every time you use it and before closing the can until next use you must add a little solvent.

Problem is proper solvent is Toluene, which has become a "controlled chemical" which is a p.i.t.a. : chemical suppliers only sell me 1 litre, tops, I have to show ID and sign for it, if I want more I have to register in a DEA controlled list and prove I actually need it, the works.

"Because it is used in drug manufacturing"

Funny thing is that when TV News show Police/DEA seizing "cocaine kitchens" in the middle of nowhere you can see lots of 200 liter/55 gallon drums full of the stuff ... WTF?

So the bad guys get all they want while real users who need it for Technical reasons must go through all the red tape ..... oh well ....

So I "downgraded" to standard wood varnish, whose solvent is cheap and not controlled, only have to wait a little more for it to dry.

No big deal.

Oh wow, controlled due to drug use? It's amazing how people don't realize how their actions harm others.

Alberta sure does have some nice scenery, however, I don't live in the mountains. We do have heavy industry, mostly oil and gas, and petrochemical, but the location plus labor costs makes mass production type manufacturing fairly unusual.

It is possible to have motors and transformers rewound, and I most probably could find someone willing to impregnate my old transformers - BUT, I'm not sure I trust my 65 year old essentially irreplaceable RCA transformers to some unknown motor rewind shop. Also, shops who are accustomed to working for oil companies or other large customers, are not going to lift a finger for an affordable price. At least that's my assumption.. also, I do have some kind of desire to do things myself... I find it kind of rewarding, even if it's not the most efficient path.

One thing I like about this wood varnish idea quite a lot, is that I won't need to heat the transformers up hot. I worry a bit that they may contain some organic materials which could be damaged by heat, at the very least I know for sure the old cloth wire leads aren't going to be rated for 150C.

Alberta sure does have some nice scenery, however, I don't live in the mountains. We do have heavy industry, mostly oil and gas, and petrochemical, but the location plus labor costs makes mass production type manufacturing fairly unusual.

It is possible to have motors and transformers rewound, and I most probably could find someone willing to impregnate my old transformers - BUT, I'm not sure I trust my 65 year old essentially irreplaceable RCA transformers to some unknown motor rewind shop. Also, shops who are accustomed to working for oil companies or other large customers, are not going to lift a finger for an affordable price. At least that's my assumption.. also, I do have some kind of desire to do things myself... I find it kind of rewarding, even if it's not the most efficient path.

One thing I like about this wood varnish idea quite a lot, is that I won't need to heat the transformers up hot. I worry a bit that they may contain some organic materials which could be damaged by heat, at the very least I know for sure the old cloth wire leads aren't going to be rated for 150C.

One more thing I didn't add earlier. The transformers I am going to be soaking have removable end covers, which are bolted to the laminations. The bolts have a double purpose of holding the laminations tight together, and holding the bell covers to the transformer. My question is, if impregnate the transformer with the bolts installed, then the varnish will have trouble to fully penetrate the windings, since there's only a small hole for the lead wires. On the other hand, if I do it with the bolts removed, then the laminations won't be clamped properly. What say the experts?

Experts!! here, we need your advice.

I have "old" amplifier transformers like that. A metallic plate cover on each side held by the 4 bolts holding the core-plates in place as well. With small holes for the wires to get outside.

My guess is that after the impregnation you cannot do any substantial work on the item without risk of doing more harm than good. A well impregnated transformer is difficult to attack. I tried with a microwave-oven transformer and that was quite a fight.

Back in the old days we had a system that allowed us to pump out for vacuum before lowering the object into the resin. This way the impregnation process is very efficient.

An idea: if you can get the end-covers off (before impregnation), could you then perforate the end covers such that flow of resin is improved? You then assemble them again before impregnation. Mechanically the perforations will not weaken the construction and shielding-wise at low frequency they will do no harm.

I have "old" amplifier transformers like that. A metallic plate cover on each side held by the 4 bolts holding the core-plates in place as well. With small holes for the wires to get outside.

My guess is that after the impregnation you cannot do any substantial work on the item without risk of doing more harm than good. A well impregnated transformer is difficult to attack. I tried with a microwave-oven transformer and that was quite a fight.

Back in the old days we had a system that allowed us to pump out for vacuum before lowering the object into the resin. This way the impregnation process is very efficient.

An idea: if you can get the end-covers off (before impregnation), could you then perforate the end covers such that flow of resin is improved? You then assemble them again before impregnation. Mechanically the perforations will not weaken the construction and shielding-wise at low frequency they will do no harm.

I could easily get this too, I really like shellac as a wood sealer, it's very easy to work with, and I like the orange tinge.

this shellac was mentioned in textbooks while still in college in the early 70's...

i guess this is a cheap way to do it...

@FauxFrench, when i dip my traffos in varnish, i do it without the bolts and nuts and end covers installed.....only the windings and the laminations.....i use bamboo sticks in place of the bolts and nuts so the traffo can be handled...

Attachments

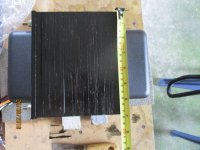

this is a finished traffo...

Really nice looking final product. I like how smooth the blue paint looks too.

Do you wait for the varnish to dry before installing the covers? I appreciate all the photos, it makes it easy to picture.

Really nice looking final product. I like how smooth the blue paint looks too.

Do you wait for the varnish to dry before installing the covers? I appreciate all the photos, it makes it easy to picture.

a week under the hot sun....and the traffo is ready to assemble...

but it takes months for those to see action in an amp...

i am purely a hobby, i am not into selling traffos like commercial winders..

so the only way for anyone to get a hold of my traffos is when they buy the completed amp.....

pure hobby, pure DIY....

this is a 58 pound traffo i recently made...

Attachments

a week under the hot sun....and the traffo is ready to assemble...

but it takes months for those to see action in an amp...

i am purely a hobby, i am not into selling traffos like commercial winders..

so the only way for anyone to get a hold of my traffos is when they buy the completed amp.....

pure hobby, pure DIY....

This is a shame, I read your other thread, and saw what kind of work you do.. COOL! I've built plenty of amps, but never wound my own transformers, and yours look interesting.

Man that one is a monster, what are you powering, an apartment building?

@FauxFrench, when i dip my traffos in varnish, i do it without the bolts and nuts and end covers installed.....only the windings and the laminations.....i use bamboo sticks in place of the bolts and nuts so the traffo can be handled...

Hi Tony,

You make very pretty (and large) transformers.

The bamboo-stick idea is really fine for your process. Using vacuum impregnation, I would fear that the resin gets in between the bamboo-stick and the hole-wall such that you cannot get the stick out again. Vacuum impregnation is really efficient in getting the resin in everywhere (also where you do not want it). This is why I advise not to expect possibility of any rework afterwards.

Keep up the good work.

I made them in various diameters and lengths, sometimes i even used some used chopsticks, recycling/repurposing is a thrill.....

It's amazing how the internet makes the world small, I don't think I've ever considered bamboo as a material to use, really for anything besides holding tomato plants up straight. It is very cool how people from all corners of the earth come here to discuss a common interest.. I usually post over at audiokarma, which is much more USA focused.

Now all I have to do is wait for Canada Post to get my vacuum chamber here!

It's amazing how the internet makes the world small, I don't think I've ever considered bamboo as a material to use, really for anything besides holding tomato plants up straight. It is very cool how people from all corners of the earth come here to discuss a common interest.. I usually post over at audiokarma, which is much more USA focused.

Now all I have to do is wait for Canada Post to get my vacuum chamber here!

indeed it is a small world....i also post at audiokarma but not as frequent as here...

actually i prefer bamboo over wooden sticks, bamboo is more pliable than wood and does not easily break in comparison..

I bought a new used compressor, which has tested successfully with my air powered vacuum pump. I've needed this for other reasons for a while, so am happy this project motivated me to jump on it. The post office left a notice that my vacuum chamber is here too, gotta pick it up today. I have a step-up transformer for operating European equipment which has some buzz, it will be the trial victim. Here's my proposed procedure with the wood varnish:

So far I have decided the procedure should be like this:

1. Pre-heat transformer to 75C, for about 2 hours to ensure temperature is even

2. Place transformer into container of varnish, put container in vacuum chamber, pull vacuum until all air is removed. Am thinking to run vacuum pump for about an hour.

3. Bring container into house, let sit for two hours at room temperature

4. Pull vacuum again, then release vacuum

4.5 - Remove transformer from varnish and place on to foil tray.

5. Put transformer into oven, bake for 4 hours at 75C

6. Let cool and remove from oven, let dry for a week.

7. Test???

I chose 75C arbitrarily, to try and make the varnish flow into the windings better. In any case, it's getting cold outside, so room temperature in the garage will probably be about 10C when I do this, so I need some kind of heat source.

Any thoughts?

So far I have decided the procedure should be like this:

1. Pre-heat transformer to 75C, for about 2 hours to ensure temperature is even

2. Place transformer into container of varnish, put container in vacuum chamber, pull vacuum until all air is removed. Am thinking to run vacuum pump for about an hour.

3. Bring container into house, let sit for two hours at room temperature

4. Pull vacuum again, then release vacuum

4.5 - Remove transformer from varnish and place on to foil tray.

5. Put transformer into oven, bake for 4 hours at 75C

6. Let cool and remove from oven, let dry for a week.

7. Test???

I chose 75C arbitrarily, to try and make the varnish flow into the windings better. In any case, it's getting cold outside, so room temperature in the garage will probably be about 10C when I do this, so I need some kind of heat source.

Any thoughts?

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Power Supplies

- How to cure buzzing chokes/transformers?