Thank you, I am really looking forward to building them. I can post a link to the forum thread when they are finalizedGood luck with your whole creation then. Let us know when ready.

I just got my boards ready. And fired them up (with heatsinks) works well. Configurated for +-5V+5V. Will be driving Soekris DAM1921. So i tested load with 33ohms for ladders and 16,5 for digital. All works well and absolutly nothing to measure at (my analoge)oscilloscope. Thanks Salas for a good solution

Attachments

BA3bal and Millet NuTube bal with UBiB 1.3

I recently changed the PSU's in my BA3 and Millett NuTube preamps with the Ubib1.3

BA3bal- Previously I was using the BiB1.1 regulators running around 450ma ccs. The 1.3's run at 350ma. Most noticeable was a sense of greater clarity and resolution and to a lesser extent more treble energy, and better transients and impact on crescendos. Salas, as per your suggestions I have used the fattest shortest wires possible 14awg stranded. Teabag's recommendation to use Nichicon LKG for C1 may also be helping. I also noticed a significant reduction in hiss at the tweeter, from around twenty inches to about eight ear to tweeter distance.

Millett Nutube bal- Previously I was using DCSTB's. Most significant change here was that violins seemed bolder, not more forward or strident in anyway, just you could hear them better. To a lesser extent an increase in clarity and transients and impact.

In both of the above preamps the Ubib1.3 is decidedly better than previous and its no going back situation. In both cases I made the Ubib platform on a separate sheet and flush mounted the bottom screws. This enables me to just place it on the bottom of the case easily. I did use heatsink compound.

Thanks Salas and Teabag.

I recently changed the PSU's in my BA3 and Millett NuTube preamps with the Ubib1.3

BA3bal- Previously I was using the BiB1.1 regulators running around 450ma ccs. The 1.3's run at 350ma. Most noticeable was a sense of greater clarity and resolution and to a lesser extent more treble energy, and better transients and impact on crescendos. Salas, as per your suggestions I have used the fattest shortest wires possible 14awg stranded. Teabag's recommendation to use Nichicon LKG for C1 may also be helping. I also noticed a significant reduction in hiss at the tweeter, from around twenty inches to about eight ear to tweeter distance.

Millett Nutube bal- Previously I was using DCSTB's. Most significant change here was that violins seemed bolder, not more forward or strident in anyway, just you could hear them better. To a lesser extent an increase in clarity and transients and impact.

In both of the above preamps the Ubib1.3 is decidedly better than previous and its no going back situation. In both cases I made the Ubib platform on a separate sheet and flush mounted the bottom screws. This enables me to just place it on the bottom of the case easily. I did use heatsink compound.

Thanks Salas and Teabag.

Attachments

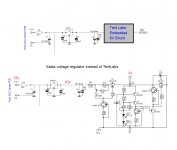

Got another question. I am considering incorporating this regulator in the DDDAC 1794 NOS DAC module for the 8vdc section. Will it work if I remove C1 as shown in the attached picture. Essentially, instead of a 6800uF there is a 10uF, but this could be increase to say 100uF.

This voltage is for Pin28 (VCC2L) on the PCM1794 dac chip which is increased from 5v to 8v on the DDDAC.

This voltage is for Pin28 (VCC2L) on the PCM1794 dac chip which is increased from 5v to 8v on the DDDAC.

Attachments

Transformer capacity and sound quality

How does the VA of a transformer affect the sound in a preamp using Ubib1.3?

Or to rephrase, what does one look for when selecting a transformer for use in a preamp? Pros and cons?

I have in my three balanced preamps used two each of the Antek AS series, in one case 50va and in the others 100VA. What can I expect in SQ if switching from 50 to 100, if anything?

Also, SQ wise what difference is expected going from toroid to Rcore?

Thoughts would be appreciated.

Thanks. nash

How does the VA of a transformer affect the sound in a preamp using Ubib1.3?

Or to rephrase, what does one look for when selecting a transformer for use in a preamp? Pros and cons?

I have in my three balanced preamps used two each of the Antek AS series, in one case 50va and in the others 100VA. What can I expect in SQ if switching from 50 to 100, if anything?

Also, SQ wise what difference is expected going from toroid to Rcore?

Thoughts would be appreciated.

Thanks. nash

Toroids are wider bandwidth components due to winding overlay able to pass more HF noise from the mains. R-Core have discrete bobbins and filter better. Subjectively sounds smoother some would say duller preferring the more upfront treble with toroids. If somewhat more dirty. R-Core are also very good for throwing minimal hum field if to be located near sensitive circuits or signal runs. Although well made toroids with careful winding and static shield + flux shield can rival any type.

More VA equals less impedance usually sounding more forceful in the midbass and bass regions. Dynamically that's more relevant to normal non CCSed PSUs that fluctuate demand. It also equals a bigger core with more field and larger inrush current torturing the rectification components. Big toroids especially can more easily trip mains breakers at power on thus NTC limiters or more elaborate soft start circuits can be seen in power amplifiers.

More VA equals less impedance usually sounding more forceful in the midbass and bass regions. Dynamically that's more relevant to normal non CCSed PSUs that fluctuate demand. It also equals a bigger core with more field and larger inrush current torturing the rectification components. Big toroids especially can more easily trip mains breakers at power on thus NTC limiters or more elaborate soft start circuits can be seen in power amplifiers.

Toroids are wider bandwidth components due to winding overlay able to pass more HF noise from the mains. R-Core have discrete bobbins and filter better. Subjectively sounds smoother some would say duller preferring the more upfront treble with toroids. If somewhat more dirty. R-Core are also very good for throwing minimal hum field if to be located near sensitive circuits or signal runs. Although well made toroids with careful winding and static shield + flux shield can rival any type.

More VA equals less impedance usually sounding more forceful in the midbass and bass regions. Dynamically that's more relevant to normal non CCSed PSUs that fluctuate demand. It also equals a bigger core with more field and larger inrush current torturing the rectification components. Big toroids especially can more easily trip mains breakers at power on thus NTC limiters or more elaborate soft start circuits can be seen in power amplifiers.

Salas, do you suggest a safety cap in parallel with the L and N lines at the PEM or any other measures before the transformers?

A while back you had suggested to me to use the the Antek AS series 100va instead of the 50va since you felt they were better made. I followed that but failed to ask why you felt so?

All these transformers come with a steel mounting bolt and cover. Any thoughts on whether nonmagnetic stainless hardware makes a better choice?

I think you have said that shunted PSU's like the Ubib1.3 work best when located very close to their consumers. Any advantage in installing the PEM and transformers in another box and feeding the secondaries thru, keeping them under say 15 inches?

Thanks for your insights. nash

Surely a slow blow primary fuse adequate for chosen VA. Primary filtering measures are optional, better having the proper Quasimodo components first.

The 100VA ones beyond having better regulation spec, their exit wires look better spaced. More core to lay the whole thing better.

I don't know enough of their mounting hardware details.

For sensitive circuits the distanced approach would be good. Even more productive if to also have rectification and snubber parts as well as an equal filter cap to C1 in the first box. Then feeding raw DC directly to the reg's own C1 with a umbilical to the second box. So the cable isn't carrying AC at all between boxes and surrounding interconnects etc.

The 100VA ones beyond having better regulation spec, their exit wires look better spaced. More core to lay the whole thing better.

I don't know enough of their mounting hardware details.

For sensitive circuits the distanced approach would be good. Even more productive if to also have rectification and snubber parts as well as an equal filter cap to C1 in the first box. Then feeding raw DC directly to the reg's own C1 with a umbilical to the second box. So the cable isn't carrying AC at all between boxes and surrounding interconnects etc.

All these transformers come with a steel mounting bolt and cover. Any thoughts on whether nonmagnetic stainless hardware makes a better choice?

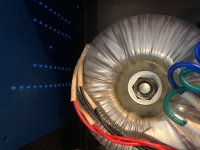

I use the Antek transformers in most of my builds. Instead of the two rubber pads and the metal plate, I tape off the bottom with packing tape, mix up a small amount of epoxy and benotite (oil dry) and pour the thickened mixture in the center to about 3/4 of the way up. When it hardens, I drill a hole in the center for the bolt (what ever material for the bolt you think is best) and use the rubber pad on the bottom. Make sure the hole is drilled prependicular. The epoxy does not support combustion like polyester type resins do. I believe this is the same procedure that Avel Lindberg uses.

See attached:

Rush

Attachments

- Home

- Amplifiers

- Power Supplies

- Salas SSLV1.3 UltraBiB shunt regulator