Hi, I'm going to be bypassing the power supply caps using 0.1 microF Mundorf Supreme caps which are suppose to be noninductive metalized polypropylene caps. Not so much as to lower ripple, but to block really high freq noise outside of the audible range. The power supply caps to be bypassed are 430 and 760 microF (voltage 500 V). Are these Mundorfs a good choice? Anyone used these in this application? Better alternative? Thanks.

This does not sound like a good idea to me. Irrespective of what their website claims, the size of the caps means that the ESL, which that manufacturer never tells you for the plastic caps, is going to be too high to do much good here. Plus, they're manufactured to have very low ESR which means that there is a chance of resonance occurring. Ie, worse sound. Much better, I believe, to try something like multi layered ceramic caps precisely where they're needed, leads as short as possible, if you want to kill very high frequency noise ...

Frank

Frank

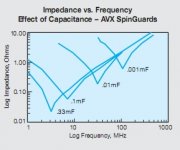

Yes, indeed they are. But the quality factor, the Q, sharpness of any resonance peak should be significantly less for that ceramic compared to the high performance plastic. What you're looking for is a curve of impedance with frequency that looks something like this:Frank, I thought ceramic caps, although very low in ESL, have virtually no ESR to speak of. So aren't ceramic caps prone to resonance as well?

That Mundorf would show a very sharp, head of a needle shape, plummeting of impedance at some frequency. And that's not good for preventing resonance. The ideal shape for that impedance behaviour is for 2 straight lines to come together to form a perfect V: that mimimises impedance over the biggest range of frequencies without encouraging resonance. Note, this is referring to very high frequencies; at audio frequencies the curve typically looks like the bottom of a bath tub with the usual capacitors used to do the work there ...

Frank

Last edited:

Thanks for the explanation. I guess I will have to return the Mundorfs, and get the ceramics to bypass each of the power supply caps. Do you have any recommendations? They have to be high voltage though, 1kV. Is 0.1 microF an appropriate value?

I was also told to bypass on the amplifier end, using a 0.1 microF cap with another larger value bypass cap (10-22 microF). Are ceramic caps available in this larger value or should I use film cap?

I was also told to bypass on the amplifier end, using a 0.1 microF cap with another larger value bypass cap (10-22 microF). Are ceramic caps available in this larger value or should I use film cap?

Ahh, high voltages of that order? That limits your options, I note that ceramics are only easily available in sizes up to 0.01uF with those ratings. And they start getting expensive too! I haven't played around with equipment using these voltages so can't really make recommendations there ...

I would still steer clear of bypassing the supply, especially if bypassing the amplifier end; this, at the actual point where the high frequencies could cause problems is where the real value of bypassing occurs. A rule of thumb is to maintain a value ratio of 50 or more when paralleling ceramic and/or film, so could use 0.01uF ceramic, 0.47uf film and 22uF film all in parallel to squash everything from a few 100kHz up to 10's of MHz. Cheap, small film cap's that can handle the voltage are the way to go, no fancy stuff. And, make the leads as short as possible, the smaller the capacitance the shorter the length of the cap lead when in place!!

Frank

I would still steer clear of bypassing the supply, especially if bypassing the amplifier end; this, at the actual point where the high frequencies could cause problems is where the real value of bypassing occurs. A rule of thumb is to maintain a value ratio of 50 or more when paralleling ceramic and/or film, so could use 0.01uF ceramic, 0.47uf film and 22uF film all in parallel to squash everything from a few 100kHz up to 10's of MHz. Cheap, small film cap's that can handle the voltage are the way to go, no fancy stuff. And, make the leads as short as possible, the smaller the capacitance the shorter the length of the cap lead when in place!!

Frank

Thanks Frank,

"I would still steer clear of bypassing the supply, especially if bypassing the amplifier end"

The reason to bypass the amplifier end is because the power supply is separate from the amplifier. I haven't decided on how long the umbilical cord would be but, it could be as long as 1 to 1.5 meter. I suppose I could get the power supply as close to the amplifier I can, so that effectively the umbilical cord will be around 10 to 15 cm. What is the reason for not bypassing the amplifier end?

"this, at the actual point where the high frequencies could cause problems is where the real value of bypassing occurs."

By actual point, you mean across each power supply cap? I have 14 power supply caps to bypass, so using those 3 bypass caps for each of the 14 power supply caps will be expensive too. Why can't I use those 3 bypass caps at the amplifier end, and skip the power supply caps? It won't be as effective, I'm guessing? If you really think bypassing each power supply cap is the way to go, I will give it serious consideration, despite the cost.

"I would still steer clear of bypassing the supply, especially if bypassing the amplifier end"

The reason to bypass the amplifier end is because the power supply is separate from the amplifier. I haven't decided on how long the umbilical cord would be but, it could be as long as 1 to 1.5 meter. I suppose I could get the power supply as close to the amplifier I can, so that effectively the umbilical cord will be around 10 to 15 cm. What is the reason for not bypassing the amplifier end?

"this, at the actual point where the high frequencies could cause problems is where the real value of bypassing occurs."

By actual point, you mean across each power supply cap? I have 14 power supply caps to bypass, so using those 3 bypass caps for each of the 14 power supply caps will be expensive too. Why can't I use those 3 bypass caps at the amplifier end, and skip the power supply caps? It won't be as effective, I'm guessing? If you really think bypassing each power supply cap is the way to go, I will give it serious consideration, despite the cost.

We have a real misunderstanding going on here now, MGH! Not quite sure how it happened, shows you how important one's choice of words is, but what I've bolded above is exactly what I would suggest strongly that you do do! In other words, bypass the amp end, don't bypass the supply end. Are we in sync now ...??Thanks Frank,

"I would still steer clear of bypassing the supply, especially if bypassing the amplifier end"

The reason to bypass the amplifier end is because the power supply is separate from the amplifier. I haven't decided on how long the umbilical cord would be but, it could be as long as 1 to 1.5 meter. I suppose I could get the power supply as close to the amplifier I can, so that effectively the umbilical cord will be around 10 to 15 cm. What is the reason for not bypassing the amplifier end?

"this, at the actual point where the high frequencies could cause problems is where the real value of bypassing occurs."

By actual point, you mean across each power supply cap? I have 14 power supply caps to bypass, so using those 3 bypass caps for each of the 14 power supply caps will be expensive too. Why can't I use those 3 bypass caps at the amplifier end, and skip the power supply caps? It won't be as effective, I'm guessing? If you really think bypassing each power supply cap is the way to go, I will give it serious consideration, despite the cost.

Frank

Haven't used any mica caps, but they should do the trick if you have them lying around. A premium product, that's again overkill, really, for the task at hand.

The trouble with using a 0.001uF cap is that something like that has to go absolutely precisely where it's needed, within a couple of mm's or so; else it's close to being worthless. The trace, lead, or wire length between it and the circuit will add too much inductance otherwise for that relatively tiny bit of capacitance in parallel to the others to do any significant good. To put things into context, 0.001uF still has an impedance of 10 ohms at 10MHz ...

If you have these values actually lying around then there should be no harm in trying it, see what difference it makes.

There is another technique, you could call it a swamping method, where you add vast numbers of caps adjacent or very close in value: 1, 1.5, 2.2, 3.3, 4.7uF, and on and on, say -- this gets very messy, and expensive. It's used in very high speed circuits and if done correctly can create a uniform, very low impedance right across the frequency spectrum. But it shouldn't be necessary in audio products, at least, I hope not!!

Frank

The trouble with using a 0.001uF cap is that something like that has to go absolutely precisely where it's needed, within a couple of mm's or so; else it's close to being worthless. The trace, lead, or wire length between it and the circuit will add too much inductance otherwise for that relatively tiny bit of capacitance in parallel to the others to do any significant good. To put things into context, 0.001uF still has an impedance of 10 ohms at 10MHz ...

If you have these values actually lying around then there should be no harm in trying it, see what difference it makes.

There is another technique, you could call it a swamping method, where you add vast numbers of caps adjacent or very close in value: 1, 1.5, 2.2, 3.3, 4.7uF, and on and on, say -- this gets very messy, and expensive. It's used in very high speed circuits and if done correctly can create a uniform, very low impedance right across the frequency spectrum. But it shouldn't be necessary in audio products, at least, I hope not!!

Frank

Last edited:

Hmm...you're giving me some good ideas. Something like this.

0.01, 0.05, 0.1, 0.5, 1, 5, 10, 50 microF caps in parallel.

There must be some mathematical sequence of cap values that will give a even overlap of frequencies. I can find 0.01, 0.05, and 0.1 in ceramic, not so sure about 1.

Wouldn't be better to get 1, 5, 10, and 50 caps in metal foil, not metalized film?

0.01, 0.05, 0.1, 0.5, 1, 5, 10, 50 microF caps in parallel.

There must be some mathematical sequence of cap values that will give a even overlap of frequencies. I can find 0.01, 0.05, and 0.1 in ceramic, not so sure about 1.

Wouldn't be better to get 1, 5, 10, and 50 caps in metal foil, not metalized film?

Last edited:

The sequence is an approximate multiple of 3; so 0.01, 0.033, 0.1, 0.33, 1, etc. These are standard values ...Hmm...you're giving me some good ideas. Something like this.

0.01, 0.05, 0.1, 0.5, 1, 5, 10, 50 microF caps in parallel.

There must be some mathematical sequence of cap values that will give a even overlap of frequencies. I can find 0.01, 0.05, and 0.1 in ceramic, not so sure about 1.

Wouldn't be better to get 1, 5, 10, and 50 caps in metal foil, not metalized film?

Be very careful if you try the "overlap" method; the values need to be quite close together, something beyond a gap of 5 times or so of the next value starts not to be good, that resonance issue begins to rear its ugly head again!

There shouldn't be any significant difference between foil, and metalised film.

Frank

Be very careful if you try the "overlap" method; the values need to be quite close together, something beyond a gap of 5 times or so of the next value starts not to be good, that resonance issue begins to rear its ugly head again!

Frank

Frank, I'm a little confused. You state gaps beyond 5 times could cause resonance, but you suggested values 50x or more in your initial response. Am I missing something? Is there some equation that predicts where the resonance will be at a particular spacing of values?

Last edited:

Frank, I'm a little confused. You state gaps beyond 5 times could cause resonance, but you suggested values 50x or more in your initial response. Am I missing something? Is there some equation that predicts where the resonance will be at a particular spacing of values?

No, there is a critical range of one value being a certain size greater or smaller from another that can cause resonance issues. The top end of this range is about 50 times, the bottom end is around 5 or so, it's a while since I looked at this closely, so I haven't got an exact number here at the moment. But 3 times is fine ...

Another way of looking at it, if the next value is spaced this number of times that of the next closest value then the combination is:

2 times - good

5 " - OK

10 - not good

15 - really bad

25 - not good

40 - OK

50 - good

Does this make more sense? Those values are very rough and ready, just to give you an idea what's going on ...

And remember this is worst for film caps, almost as bad for ceramic. Electrolytics are totally benign, never a worry in this regard. And can be combined with film and ceramic without any problems, no matter what the value. In fact, the solid polymer variety, the Sanyo OS-CON and their bretheren would be brilliant to use everywhere, but they can't take any reasonable voltages ... bummer!

And I can't emphasise too strongly that the real benefit of doing this exercise is for all leads, wiring to be as absolutely as short as possible. If you can't physically add this bypassing exactly where it needs to go, to have as close to zero wire length as you can possibly organise, then don't do it, it won't do the job!

Frank

Exactly. Just throwing in cap's willy nilly may give one an improvement. Or it may not. Depending on how carefully and precisely one positions them. And again, it is most critical to keep the lengths shortest on the smallest value caps, and they should be the ones most precisely positioned in the circuit where they're needed to do the job. The larger caps can be allowed a bit more lead length to fit them in, and I've created little sculptures in space at times just to have the ideal configuration for minimal lead lengthSeems difficult with so many caps to keep the wire length minimal. May be it's simpler and practically just as effective if I go with your original recommendation of 0.01, 0.47, and 22. But it's hard to find a 22 microF film cap that is small.

I agree that it will probably be just as effective for an audio environment to use the widely spaced combination. Ultimately, the trick is just to try out how much of a difference it makes doing this sort of bypassing; if the change in sound is very significant then it is probably worthwhile seeing if going the overlapping values route is even more beneficial ...

Don't get paranoid about the larger values being physically large - it just equates to having a slightly longer lead length, and then see above! In simple terms, size and length means more residual inductance, which cancels out the effectiveness of the capacitance at higher frequencies. Unless, the manufacturer has gone to great lengths to minimise this, which he will surely crow about ...

Frank

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Power Supplies

- Mundorf M-Cap Supreme as bypass cap?