Thanks Dave.

The braces look easy enough to add in. A couple more questions specific to the Pensil-7 if I may:

a) Would you strongly advise building out of ply or MDF rather than, say, solid maple or oak? Would you change the board thickness if building out of solid wood? Speaking only of sound quality without regard to cost, are there any wood selection guidelines that should be respected? And finally, would it be advisable to "deaden" the wood with felt or something on the inside?

b) Came across these in another post on wood-working and I quite like the look of the baffle being in a different wood. Is this something I could do with the Pensil design or is this going to destroy the acoustics?

http://www.blumenstein-ultra-fi.com/uploads/images/Gallery/naga/1.jpg

Thanks,

Colin

The braces look easy enough to add in. A couple more questions specific to the Pensil-7 if I may:

a) Would you strongly advise building out of ply or MDF rather than, say, solid maple or oak? Would you change the board thickness if building out of solid wood? Speaking only of sound quality without regard to cost, are there any wood selection guidelines that should be respected? And finally, would it be advisable to "deaden" the wood with felt or something on the inside?

b) Came across these in another post on wood-working and I quite like the look of the baffle being in a different wood. Is this something I could do with the Pensil design or is this going to destroy the acoustics?

http://www.blumenstein-ultra-fi.com/uploads/images/Gallery/naga/1.jpg

Thanks,

Colin

Colin:

to elaborate on Dave's post - I'd suggest you consider interlocking holey braces on an enclosure as tall and skinny as the Pensils for 7s would be. I recently built a pair with removable backs to allow for playing with stuffing levels, (highly recommend that for any of the Pensils) and ran one brace front to back from top to approx 2/3 the internal length, then a second brace side to side which interlocked by about 1".

It certainly takes longer to fabricate and fit the braces than the rest of an enclosure as simple as these, but definitely makes for very stiff and tight construction.

edit:

If you're confident that you could build a pair of these from solid wood that would stay together, by all means, but if not I'd strongly recommend plywood or even particle board over MDF.

regardless of material you decide for main carcass, there's no reason that something like Clark's solid wood mounting plate wouldn't work.

knowing Clark, it's probably not entirely cosmetic

to elaborate on Dave's post - I'd suggest you consider interlocking holey braces on an enclosure as tall and skinny as the Pensils for 7s would be. I recently built a pair with removable backs to allow for playing with stuffing levels, (highly recommend that for any of the Pensils) and ran one brace front to back from top to approx 2/3 the internal length, then a second brace side to side which interlocked by about 1".

It certainly takes longer to fabricate and fit the braces than the rest of an enclosure as simple as these, but definitely makes for very stiff and tight construction.

edit:

If you're confident that you could build a pair of these from solid wood that would stay together, by all means, but if not I'd strongly recommend plywood or even particle board over MDF.

regardless of material you decide for main carcass, there's no reason that something like Clark's solid wood mounting plate wouldn't work.

knowing Clark, it's probably not entirely cosmetic

Last edited:

Building a box out of solid wood -- and having it hold together under humidity & temperature changes -- is a big challenge. Quite a few of these are being made out of solid, particularily in Japan & HK, we'll see how long lived they are.

The safer bet would be good multiply clad with real wood, with a viscoelastic bonding agent. IMHO MDF is suitable only in situations where it is all you can get,

dave

The safer bet would be good multiply clad with real wood, with a viscoelastic bonding agent. IMHO MDF is suitable only in situations where it is all you can get,

dave

Just finished a 'sample' build of the pensil-p70 with a pair of chp-70 I ordered, and I'm gobsmacked! I did a quick build using mdf and no frills just to test them out (I have to confess that I was actually very skeptical and wanted to hear for myself what all this FR fad was about), and I can't believe the sound that's coming out of the little drivers!

Onward to a rather more 'luxurious' and careful build now. Thanks guys for great plans, product and advice.

Onward to a rather more 'luxurious' and careful build now. Thanks guys for great plans, product and advice.

Just finished a 'sample' build of the pensil-p70 with a pair of chp-70 I ordered, and I'm gobsmacked! I did a quick build using mdf and no frills just to test them out (I have to confess that I was actually very skeptical and wanted to hear for myself what all this FR fad was about), and I can't believe the sound that's coming out of the little drivers!

Onward to a rather more 'luxurious' and careful build now. Thanks guys for great plans, product and advice.

Hello Mac1963,

Welcome to the world of Full-Range. Feel free to post some pics. Always interesting to show various stages of a project.

Have fun!

Cheers

Mark.

Hi all

Finally found the time to post some pictures of the final result. Solid Sucupira (sliced up and rejoined to avoid warping) was used, and the sound is AMazing! Thanks again, guys, for the info and support that made these possible.

Finally found the time to post some pictures of the final result. Solid Sucupira (sliced up and rejoined to avoid warping) was used, and the sound is AMazing! Thanks again, guys, for the info and support that made these possible.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Thanks guys.

Being a regular guy who can't leave well enough alone, I'm considering trying se spikes to see if they make a difference. Am also supposed to put in an aluminum inlay in the visible 2mm shadow gaps running along the top and front. The idea was to add a visible effect here. However I'm not so sure I'm going to do that as I really like them 'as is' and the gap seems to have no notable negative effect on the sound…

Being a regular guy who can't leave well enough alone, I'm considering trying se spikes to see if they make a difference. Am also supposed to put in an aluminum inlay in the visible 2mm shadow gaps running along the top and front. The idea was to add a visible effect here. However I'm not so sure I'm going to do that as I really like them 'as is' and the gap seems to have no notable negative effect on the sound…

Hi Scott/Dave,

Which aspects of the Pencils' dimensions are critical? I'd like to play with the idea of curved side panels. If I keep the enclosure height and cross sectional area the same my hunch is the tuning will be unchanged. Is that a reasonable assumption?

Thanks

So far so good I think, but I'd raise the questions of curved in what direction and what fabrication technique did you have in mind?

the millwork trade has a simple abbreviation - "CCM" no matter what materials / techniques are employed, curves cost money

note from the "white papers"

So I think that you'd want to be careful that bracing/support framing for curved panels didn't interfere with the QW action. If you'll note from Dave's drawings and pictures posted elsewhere, panel bracing on these is best oriented vertically.The Pencils are a small range of easy-to-build floorstanding cabinet designs for Mark Fenlon Audio drivers. They use a combination of traditional quarter-wave design, a custom T/S volume alignment, and Transmission Line damping to provide a balanced response with a flavour of both vented and TL enclosures.

Depending on the particular drivers being used, the Pensil can be a pretty skinny box, making access to adjust damping / fill levels a bit a of a challenge, so at the very least I'd consider fabrication with either front or rear panel removable

Which aspects of the Pencils' dimensions are critical?

Cross section area, line length (height), driver placement from the top, terminus area, placement* & depth (don't go building a 2" baffle)

* ignoring room effects, they have been successfully placed on the back and should be no issue on the side.

dave

panel bracing on these is best oriented vertically.

Regardless of box, bracing is best placed longitudinally (ie along the longest dimension and not at the centre of a panel).

This is more formally stated as: The brace should divide the panel such that the sub panels have a larger aspect ratio than the original panel.

dave

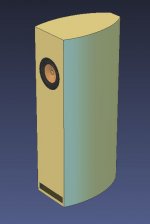

Well my curvy Pensil 10.2 works out at 425 deep with a random by eye boat profile, 17mm deeper than regular. I have assumed 18mm material and kept the cross sectional area, height and baffle the same. I think its a looker, which is important to me. I'm tempted to build it!

Attachments

I think its a looker

It is indeed! Very nice.

Well my curvy Pensil 10.2 works out at 425 deep with a random by eye boat profile, 17mm deeper than regular. I have assumed 18mm material and kept the cross sectional area, height and baffle the same. I think its a looker, which is important to me. I'm tempted to build it!

looks great - how where you contemplating fabricating the curved wall panels?

Well my curvy Pensil 10.2 works out at 425 deep with a random by eye boat profile, 17mm deeper than regular. I have assumed 18mm material and kept the cross sectional area, height and baffle the same. I think its a looker, which is important to me. I'm tempted to build it!

Stunning! I had a set of Rockets (RS450's and RSC200) that have curved sides and they look great. VERY similar profile to what you have suggested. Go for it!!

Scott

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- More Vendors...

- Planet 10 hifi

- Pensil Series for Mark Audio Drivers