This one has been a long time coming. A "Phd" (project half done) finally conquered. In the past I have built exotic amplifiers(solid state and vacuum tube), PEQ equalizers, huge conventional speakers but still felt something missing. The final link in the chain lacked, even to my untrained ears, that quickness. I would grow older, ears duller and ever be a forums lurker. Till this day...

My journey began 7-8 years ago, when I began collecting parts for the project, and scouring forums on choosing the right build for me. I almost settled on a curved perforated metal type two years ago, when I was drawn to the Segmented Stretched Wire design, by my mentor and forever patient CharlieM (aka Jazzman). This ESL build is based on one of his many designs and well documented on his blog. Without which ,it would have been a herculean task. This thread starts with my utter appreciation and heartful thanks to CharlieM.

My journey began 7-8 years ago, when I began collecting parts for the project, and scouring forums on choosing the right build for me. I almost settled on a curved perforated metal type two years ago, when I was drawn to the Segmented Stretched Wire design, by my mentor and forever patient CharlieM (aka Jazzman). This ESL build is based on one of his many designs and well documented on his blog. Without which ,it would have been a herculean task. This thread starts with my utter appreciation and heartful thanks to CharlieM.

Attachments

Last edited:

I'm more a machinist , than a carpenter. Thats how I approached the build , and moreover dimensions converted to the metric system.

Here , the many panels cut from 19.05mm (3/4") AAA grade Oak Plywood. All the stator panel pieces from solid oak.

Here , the many panels cut from 19.05mm (3/4") AAA grade Oak Plywood. All the stator panel pieces from solid oak.

Attachments

WOW! What a nice surprise.

It's about time someone posted a build-from-scratch project here again. You should be very proud... beautiful work!

I would love to hear them.

My experience using similar panels is that you needn't worry about them. I really don't think you can hurt them, even if you push them hard enough to occasionally drive the diaphragm into a stator.

Enjoy!

It's about time someone posted a build-from-scratch project here again. You should be very proud... beautiful work!

I would love to hear them.

My experience using similar panels is that you needn't worry about them. I really don't think you can hurt them, even if you push them hard enough to occasionally drive the diaphragm into a stator.

Enjoy!

Last edited:

Those look gorgeous. Is the wire stretched on wood? Are the insulation properties of the wood good enough that humidity can't cause a problem?

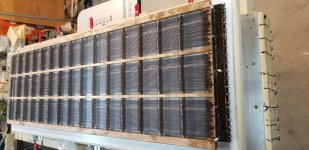

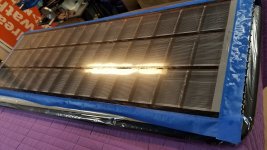

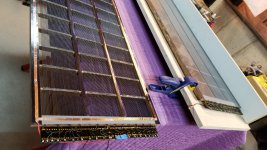

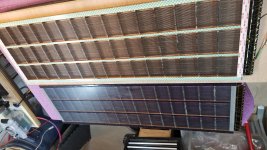

The wire was first stretched on a stretching jig, till the single core copper is mechanically (plastic)deformed and stays straight when relaxed. This process is supposed to harden it as well.

The wooden lattice is then glued on, with the wires relaxed just enough.

The whole lattice and frame fit like a jigsaw puzzle. Hence, I believe even in high humidity will stay put. If you mean what about arcing ??, unless there is a nick in the wire insulation, that is a thing of the past.

Attachments

Last edited:

WOW! What a nice surprise.

It's about time someone posted a build-from-scratch project here again. You should be very proud... beautiful work!

I would love to hear them.

My experience using similar panels is that you needn't worry about them. I really don't think you can hurt them, even if you push them hard enough to occasionally drive the diaphragm into a stator.

Enjoy!

Thank You Charlie !!!

Yeah, the videos are coming.

I'm still trying to drive the diaphragms into the stators, without making my ears bleed.

People who have heard them , swear it sounded like a live band playing if behind a curtain.

Some more pictures.

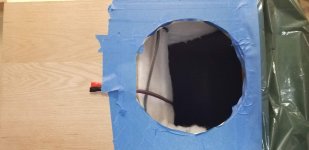

Here is the diaphragm stretcher, with mylar just before stretching. Then with the Lattice attached and then sprayed with anti-static

Here is the diaphragm stretcher, with mylar just before stretching. Then with the Lattice attached and then sprayed with anti-static

Attachments

More pics of a panel in various stages of assembly...

Attachments

Some more pictures.

Here is the diaphragm stretcher, with mylar just before stretching. Then with the Lattice attached and then sprayed with anti-static

Amazing how far you can actually stretch a bike tube

Amazing how far you can actually stretch a bike tube

LOL, Yeah...

Hi. What's your experience as far as how much amplifier is needed to drive this speaker?

TIA.

Here is the hardware I use ... the panel driver/ high voltage setup. The amplifier is a simple four channel amp that i built comprising of four ICEpower 125ASX2 modules. The crossover is the minidsp SHD, doing a number of things all in one box. I wanted to go with a simple , yet powerful setup and not make the room look like a ICBM command center.

I found these amps to be adequate for the speaker size. They can go really loud in layman terms.

Attachments

Just reviewing your build again and finding it even more impressive. Attention to the small details really sets your build apart.

I'm sure the EMCO 4K bias supply, coupled with the optimum wire spacing of your panels, gives excellent efficiency for an ESL. I'm thinking I might pick up a couple of those EMCO units for cheap on Ebay, and give them a whirl.

I would love to build your speaker-- just don't know if I have the energy for it these days. Believe me; I fully grasp and appreciate the effort and anguish involved in a project like yours.

Actually; I'm contemplating a different design path to post on my website-- something simple, easy, and cheap, but still has that magical ESL sound. It wouldn't be a work of art like yours, of course, but it would be more accessible for others to build.

Thanks again for sharing your magnificent speakers!

I'm sure the EMCO 4K bias supply, coupled with the optimum wire spacing of your panels, gives excellent efficiency for an ESL. I'm thinking I might pick up a couple of those EMCO units for cheap on Ebay, and give them a whirl.

I would love to build your speaker-- just don't know if I have the energy for it these days. Believe me; I fully grasp and appreciate the effort and anguish involved in a project like yours.

Actually; I'm contemplating a different design path to post on my website-- something simple, easy, and cheap, but still has that magical ESL sound. It wouldn't be a work of art like yours, of course, but it would be more accessible for others to build.

Thanks again for sharing your magnificent speakers!

To call this "astonishing" hardly covers the accomplishment. Astonishing in every way.

(BTW, I use an EMCO module for bias, driven by a variable DC 12v power supply from eBay (with a voltmeter output display all for $15) which is powered by a wall-plug DC power supply. Piece of cake.)

(BTW, I use an EMCO module for bias, driven by a variable DC 12v power supply from eBay (with a voltmeter output display all for $15) which is powered by a wall-plug DC power supply. Piece of cake.)

Just reviewing your build again and finding it even more impressive. Attention to the small details really sets your build apart.

I'm sure the EMCO 4K bias supply, coupled with the optimum wire spacing of your panels, gives excellent efficiency for an ESL. I'm thinking I might pick up a couple of those EMCO units for cheap on Ebay, and give them a whirl.

I would love to build your speaker-- just don't know if I have the energy for it these days. Believe me; I fully grasp and appreciate the effort and anguish involved in a project like yours.

Actually; I'm contemplating a different design path to post on my website-- something simple, easy, and cheap, but still has that magical ESL sound. It wouldn't be a work of art like yours, of course, but it would be more accessible for others to build.

Thanks again for sharing your magnificent speakers!

Hi Charlie, Thank You. While the EMCO look pretty, You may want to hold off. i've had a second one fail , and i'm running them below their working voltage. Besides they're still pricy for used ones from Embay. I'm looking at other options now. Hence, the delay in me getting some videos out on the speakers.

To call this "astonishing" hardly covers the accomplishment. Astonishing in every way.

(BTW, I use an EMCO module for bias, driven by a variable DC 12v power supply from eBay (with a voltmeter output display all for $15) which is powered by a wall-plug DC power supply. Piece of cake.)

Hi Ben, Thanks.

Haha, same setup here on the EMCO's . They're max 15v input and failing at 12vdc. And forget about new ones.

Truly outstanding looking speakers! Are your EMCO modules set up for variable output? Like bentoronto, I use an one with a variable LM317 power supply....simple but very effective .

Hi Bondsan,

Thanks. Yes exactly the same with a variable PS and display. But as i mentioned are failing. No idea why.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- An Segmented Hybrid ESL. In the footsteps of Jazzman.