It has happened. Our lounge has been redecorated and my much-loved ESL 2805s look even more obtrusive (big, dark grey) than before. Rather than let them go  I’m hoping to replace the cloth with something more in keeping with the room’s decor.

I’m hoping to replace the cloth with something more in keeping with the room’s decor.

However Googling for information about how to replace the cloth has found nothing. Indeed there’s little on the ‘Net about servicing ESL 2805/2905s. This site has a useful thread about accessing the electronics board (to repair the power supply) but of course the dismantling goes only as far as necessary for that purpose.

If you’re reading this and have any knowledge relevant to my intended job, replacing the cloth on Quad ESL 2805s (and I expect that the same job would be very similar on ESL 2905s) please reply.

However Googling for information about how to replace the cloth has found nothing. Indeed there’s little on the ‘Net about servicing ESL 2805/2905s. This site has a useful thread about accessing the electronics board (to repair the power supply) but of course the dismantling goes only as far as necessary for that purpose.

If you’re reading this and have any knowledge relevant to my intended job, replacing the cloth on Quad ESL 2805s (and I expect that the same job would be very similar on ESL 2905s) please reply.

Hello, I use a 2905, last month I accidentally remove the cloth when I was trying to reach the panels.

As I remember;

- Pull the black thing on the top of the speaker (facing to the ceiling)

- Then you should remove the grey profiles from the sides by unscrewing its screws from top then lay the speaker down and unscrew from bottom. After you do it you will see nuts at the bottom side.

- After removing the side profiles, you will see many screws each side facing front unscrew them and the grill will be released with the cloth

As I remember;

- Pull the black thing on the top of the speaker (facing to the ceiling)

- Then you should remove the grey profiles from the sides by unscrewing its screws from top then lay the speaker down and unscrew from bottom. After you do it you will see nuts at the bottom side.

- After removing the side profiles, you will see many screws each side facing front unscrew them and the grill will be released with the cloth

Spandex is a material to use if you want a variety of colors.

If you hold this material up to the light you can vary the angles and still see it has a decent

Penetration of light and thus sound.

Other materials dont fare so well in this same test.

Getting rid of it is even better but understand the WAF factor

Regards

David

If you hold this material up to the light you can vary the angles and still see it has a decent

Penetration of light and thus sound.

Other materials dont fare so well in this same test.

Getting rid of it is even better but understand the WAF factor

Regards

David

Last edited:

OK, now on to your question with a serious reply. I remove the grilles from the 2805/2905/2812/2912 thusly:

I start by removing each decorative plate on either side of the base of the speaker facing the floor. A single screw holds the plate in place.

I then push a rod up through a gap between the outer metal extrusion and the inside edge of the speaker the whole way up to the top to push the decorative wooden top piece off. The wooden top piece which is held in place with rubber friction bushings at the top of the speaker.

The side pieces are then removed by loosening a 14mm nut under each one (behind the decorative plates you removed) and then removing two machine screws at the top of each one. The side piece pivots outward from the top and then slides downward off the threaded stud and is free.

You then de-tension the support rod at the back and remove the 14mm nut at the top of the speaker holding the rod in place. You will have to adjust the tensioning nut at the bottom to get the tension rod the right length so the threaded stud can slip out through the hole in the rear grille.

You then unscrew the sheet metal flat-head screws down each side of the front and rear grilles.

They pull directly away from the speaker body after those fasteners are removed. The little tacky light-up quad logo has to be unplugged from the front grille when it is removed.

The grille cloth is held to the grilles with velcro around the perimeter. I recommend the paisley above...

Now for some warnings:

The fasteners Quad uses in these speakers are some of the crappiest and softest metal fasteners the world has ever seen. The pan head sheet metal screws at the top that hold on the side pieces can easily strip. And the flat head machine screws that hold the grilles on are also very easy to strip.

To add insult to injury, I believe they are JIS fasteners, not phillips fasteners. So you really should use a JIS screwdriver, and at the very least, go buy a brand new driver and be super careful. I use a Vessel JIS driver and they come right out without even damaging the paint.

Hope that helps,

Sheldon

quadesl.com

I start by removing each decorative plate on either side of the base of the speaker facing the floor. A single screw holds the plate in place.

I then push a rod up through a gap between the outer metal extrusion and the inside edge of the speaker the whole way up to the top to push the decorative wooden top piece off. The wooden top piece which is held in place with rubber friction bushings at the top of the speaker.

The side pieces are then removed by loosening a 14mm nut under each one (behind the decorative plates you removed) and then removing two machine screws at the top of each one. The side piece pivots outward from the top and then slides downward off the threaded stud and is free.

You then de-tension the support rod at the back and remove the 14mm nut at the top of the speaker holding the rod in place. You will have to adjust the tensioning nut at the bottom to get the tension rod the right length so the threaded stud can slip out through the hole in the rear grille.

You then unscrew the sheet metal flat-head screws down each side of the front and rear grilles.

They pull directly away from the speaker body after those fasteners are removed. The little tacky light-up quad logo has to be unplugged from the front grille when it is removed.

The grille cloth is held to the grilles with velcro around the perimeter. I recommend the paisley above...

Now for some warnings:

The fasteners Quad uses in these speakers are some of the crappiest and softest metal fasteners the world has ever seen. The pan head sheet metal screws at the top that hold on the side pieces can easily strip. And the flat head machine screws that hold the grilles on are also very easy to strip.

To add insult to injury, I believe they are JIS fasteners, not phillips fasteners. So you really should use a JIS screwdriver, and at the very least, go buy a brand new driver and be super careful. I use a Vessel JIS driver and they come right out without even damaging the paint.

Hope that helps,

Sheldon

quadesl.com

Sheldon, again very helpful and informative. I am still thankful for your help regarding the broken power supply of my 2805' s.

No problem, I'm glad to help.

I'm still shocked that I don't have people lining up for my paisley quad grille cloth shown above.

Sheldon

Paisley is very nice.

On the floor you can see the a bank of oil-filled high voltage B+ (2400 Vdc) capacitors for my direct-drive high voltage amp. 1979.

After resting for nearly 40 years, recently brought these panels (and the paisley covers) back into use as the main speakers, crossing over around 135 Hz. But the fantastic DD amp is long-since gone to another home.

B.

On the floor you can see the a bank of oil-filled high voltage B+ (2400 Vdc) capacitors for my direct-drive high voltage amp. 1979.

After resting for nearly 40 years, recently brought these panels (and the paisley covers) back into use as the main speakers, crossing over around 135 Hz. But the fantastic DD amp is long-since gone to another home.

B.

Attachments

Last edited:

I brought up my idea of building a Direct Drive amp for the treble panels of my (to be) stacked ESL57s in the PASS forum and got a somewhat lukewarm interest (well I got some friendly warnings about how extremely lethal such an undertaking would be)).

Slew rate needed to drive about 600 pF of panels (about 50 mA current capacity should do)

Maybe more enthusiastic support in this forum

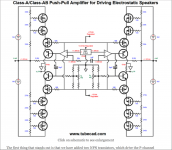

A possible schematic below (all solid state with

MOSFETs handling Vdss;max =2500V) -- courtesy of John Broskie @tubecad.com

This amp would swing about 2 kVp, which is close the the lever zener clamps for the ESL57 are built. The bass panels will be driven through the stock step-up transformer.

A truly scary but fun project. Will start as soon I receive my refurbed panels.

Slew rate needed to drive about 600 pF of panels (about 50 mA current capacity should do)

Maybe more enthusiastic support in this forum

A possible schematic below (all solid state with

MOSFETs handling Vdss;max =2500V) -- courtesy of John Broskie @tubecad.com

This amp would swing about 2 kVp, which is close the the lever zener clamps for the ESL57 are built. The bass panels will be driven through the stock step-up transformer.

A truly scary but fun project. Will start as soon I receive my refurbed panels.

Attachments

Looking at that schematic, I understand why high voltage tubes might still make good sense.

My panels were made DIY from six Dayton-Wright cells which are designed much more robust in all aspects than Quads and can run at higher than 12kv bias in their manufactured speaker welding-gas environment.

B.

My panels were made DIY from six Dayton-Wright cells which are designed much more robust in all aspects than Quads and can run at higher than 12kv bias in their manufactured speaker welding-gas environment.

B.

Maybe more enthusiastic support in this forum

I'm also going to be luke-warm abut it. Not because direct drive is a bad idea, but more the concept that you want to do that to the quads.

That's like dropping a small block chevy motor in an e-type jag. Sure, you can do it, but it ruins the value and is not at all in line with the original design intent.

The treble panels arc at about 3000v across them. So you'll need some pretty healthy rail voltages.

Sheldon

I share Sheldon's opinion but for the speaker and for the car, the choices for those particular items are aesthetic rather than technical about performance. The amp is upstream....That's like dropping a small block chevy motor in an e-type jag. Sure, you can do it, but it ruins the value and is not at all in line with the original design intent. ...

B.

My more pragmatic and lukewarm self does agree with you...

...but where is the enthusiasm, guys?

I think the ESL57 is a great speaker worth the effort of some experimentation. It may be tricky to recreate phase and FR behaviour, so that overall tonal balance may not be as good as the original. That would a failure.

On the other hand it could remove some of the 'muddy' behaviour with complex music. That would be a success. I think I have the measurement tools to mimic the original quite close. Would also be interesting to see how much the distorsion levels will go down - closer to ESL63 0.1% level or is it just the lower precision in the panel design that makes up the that difference.

On that note, maybe the ESL63 is a better platform "worthy of" a DD connection, but the electrical design calls for higher voltages and much higher currents (need to build full range as I see it), so the DD cost would easily be 2-4x of my limited experiment.

More like dropping a Tesla motor in an e-type jag (without changing the vintage exterior). Well, Tesla is a bad analogy really since DD removes coils and magnetic forces from the signal chain...

Not sure what you mean which value ruined, but in practical terms this is about moving four wires (coming from the treble panel) from the transformer to a small plastic box beside the transformer containing a subset of the xover and a connection to a short HV 'umbilical cord' to the HV amp on the floor.

Would take < 1hr to restore the 57 to its original design.

Cost of building the HV amp is (mostly) value ruined of course if this turns out as a failure (no improvement or worse), but that is true of most DIY stuff, whether done on the primary or secondary side of the transformer...

Planned rail voltage to allow swing of 2200-2400 V (around zener clamp level) and thus also a margin to the arc voltage.

Realize I'm totally OT since I hijacked this thread about 2805/2905 cloth replacement. Sorry about that. Thought earlier I should start a separate thread in this forum on DD experiences-pros/cons...but my DD ideas maybe ought to come to rest hidden in in cloth replacement

...but where is the enthusiasm, guys?

I think the ESL57 is a great speaker worth the effort of some experimentation. It may be tricky to recreate phase and FR behaviour, so that overall tonal balance may not be as good as the original. That would a failure.

On the other hand it could remove some of the 'muddy' behaviour with complex music. That would be a success. I think I have the measurement tools to mimic the original quite close. Would also be interesting to see how much the distorsion levels will go down - closer to ESL63 0.1% level or is it just the lower precision in the panel design that makes up the that difference.

On that note, maybe the ESL63 is a better platform "worthy of" a DD connection, but the electrical design calls for higher voltages and much higher currents (need to build full range as I see it), so the DD cost would easily be 2-4x of my limited experiment.

That's like dropping a small block chevy motor in an e-type jag.

More like dropping a Tesla motor in an e-type jag (without changing the vintage exterior). Well, Tesla is a bad analogy really since DD removes coils and magnetic forces from the signal chain...

it ruins the value

Not sure what you mean which value ruined, but in practical terms this is about moving four wires (coming from the treble panel) from the transformer to a small plastic box beside the transformer containing a subset of the xover and a connection to a short HV 'umbilical cord' to the HV amp on the floor.

Would take < 1hr to restore the 57 to its original design.

Cost of building the HV amp is (mostly) value ruined of course if this turns out as a failure (no improvement or worse), but that is true of most DIY stuff, whether done on the primary or secondary side of the transformer...

The treble panels arc at about 3000v across them. So you'll need some pretty healthy rail voltages.

Planned rail voltage to allow swing of 2200-2400 V (around zener clamp level) and thus also a margin to the arc voltage.

Realize I'm totally OT since I hijacked this thread about 2805/2905 cloth replacement. Sorry about that. Thought earlier I should start a separate thread in this forum on DD experiences-pros/cons...but my DD ideas maybe ought to come to rest hidden in in cloth replacement

Last edited:

Mats,

You are 100% correct. We should be more enthusiastic about it. But from my perspective, it is troubling. As someone who has fixed the quads for the last 25 years, I have a few observations, but the main two are: The construction quality is abysmal and the precision of the panels leaves a lot to be desired. And, very few panels are in really good shape anymore, so you are going to be dealing with rebuilding the speaker or working with sub-optimal panels.

Your task of building a DD amp for an electrostat is a very ambitious project and I'm excited to watch your progress and help out if I can. But it seems like that huge amount of work is going to be wasted DDing half of the quads (the bass panels play way up into the midrange). It seems to me that building a modern ESL with a flat segmented stator for good dispersion and driving it with your DD amp would make a much better project. You could tailor your amp to the needs of the speaker and the speaker to the limitations of the drive of the amp. The stators could be circuit boards with the conductive portions buried in a middle layer. Now that's a project to get excited about.

Edit: Don't be discouraged, and feel free to ask me questions if you think I might know something. I'm just a middle aged dude who is practicing to be a crotchety old man. Carry on.

Sheldon

You are 100% correct. We should be more enthusiastic about it. But from my perspective, it is troubling. As someone who has fixed the quads for the last 25 years, I have a few observations, but the main two are: The construction quality is abysmal and the precision of the panels leaves a lot to be desired. And, very few panels are in really good shape anymore, so you are going to be dealing with rebuilding the speaker or working with sub-optimal panels.

Your task of building a DD amp for an electrostat is a very ambitious project and I'm excited to watch your progress and help out if I can. But it seems like that huge amount of work is going to be wasted DDing half of the quads (the bass panels play way up into the midrange). It seems to me that building a modern ESL with a flat segmented stator for good dispersion and driving it with your DD amp would make a much better project. You could tailor your amp to the needs of the speaker and the speaker to the limitations of the drive of the amp. The stators could be circuit boards with the conductive portions buried in a middle layer. Now that's a project to get excited about.

Edit: Don't be discouraged, and feel free to ask me questions if you think I might know something. I'm just a middle aged dude who is practicing to be a crotchety old man. Carry on.

Sheldon

Last edited:

Many thanks for the supportive comments, Sheldon. Appreciated!

And of course I agree that it would be better to DD the bass panels as well,

but the voltages and currents introduced would make the DD amp even more exotic (and lethal) (and expensive)...Maybe as a 2nd step if step 1 provides a clear objective and subjective improvement

It is sad that so little R&D seems to be put into development of next generation electrostatic solutions...new materials and new production methods should make it possible to produce panels at low cost/high volumes and with extreme tolerances. Don't know ML that well but the QUAD story after 1981 is not very impressing --- the same panels for nearly 40 years (even signs that panel quality decreases).

Would be depressing if the next QUADs "2820" and "2920" (if they materialise) would just be minor changes in looks and some marketing BS about new high quality resistors and capacitors (as with the 2812/2912).

And of course I agree that it would be better to DD the bass panels as well,

but the voltages and currents introduced would make the DD amp even more exotic (and lethal) (and expensive)...Maybe as a 2nd step if step 1 provides a clear objective and subjective improvement

It is sad that so little R&D seems to be put into development of next generation electrostatic solutions...new materials and new production methods should make it possible to produce panels at low cost/high volumes and with extreme tolerances. Don't know ML that well but the QUAD story after 1981 is not very impressing --- the same panels for nearly 40 years (even signs that panel quality decreases).

Would be depressing if the next QUADs "2820" and "2920" (if they materialise) would just be minor changes in looks and some marketing BS about new high quality resistors and capacitors (as with the 2812/2912).

As a Dayton-Wright enthusiast I am biased. But my gut feeling on looking at first generation Quad panels is that they are made by teenagers in somebody's garage. Junk grade.... The construction quality is abysmal and the precision of the panels leaves a lot to be desired....

And as compared to DW stuff (also made by teenagers) but really looks like MIL-SPEC solid. That's partly because the regulatory bodies in nanny Canada hounded Mike Wright endlessly about safety issues in his gear.

Re mats31 post, the DW cells are rock-solid plastic moldings but easily mass produced. No reason ESLs shouldn't be easy to make cheap, aside from the fact that today, they have to interface with low output impedance amps and so need fancy transformers. Too bad.*

B.

* making curved panels out of 6 DW cells is a swell configuration, like Janszen of yore; pity that DIY crowd tends to focus on single large (sometimes curved) cells rather than an array of easily fabricated small cells

Last edited:

It is sad that so little R&D seems to be put into development of next generation electrostatic solutions...new materials and new production methods should make it possible to produce panels at low cost/high volumes and with extreme tolerances.

That's true, but Hi-Fi is dying and everybody seems to want postage stamp sized speakers. I have to say that modern small speakers really are pretty good for what they are. But there just isn't that much demand for high end audio.

Don't know ML that well but the QUAD story after 1981 is not very impressing --- the same panels for nearly 40 years (even signs that panel quality decreases).

Would be depressing if the next QUADs "2820" and "2920" (if they materialise) would just be minor changes in looks and some marketing BS about new high quality resistors and capacitors (as with the 2812/2912).

Quad had about 3 or 4 versions of the ESL63 electronics. Then from the last ESL63's onwards the speakers are virtually identical inside.

Also I have a set of the 2912's, and there is nothing "High quality" about the resistors and capacitors. Sand cast resistors, and enough room for a film cap instead of the input electrolytic, but no effort to replace that electrolytic or even bypass it with a film cap. The only innovation in the last two models is the tacky little light up quad logo...

Sheldon

As a Dayton-Wright enthusiast I am biased. But my gut feeling on looking at first generation Quad panels is that they are made by teenagers in somebody's garage. Junk grade.

Them's fighting words for a lot of folks. However you won't hear an argument from me. I'm really impressed at how marginal they look yet how well they can work and how long they have lasted. They do have that "science fair project" look to them. That's why I am always hesitant to sell a pair to someone who has never seen or heard them.

And as compared to DW stuff (also made by teenagers) but really looks like MIL-SPEC solid. That's partly because the regulatory bodies in nanny Canada hounded Mike Wright endlessly about safety issues in his gear.

The 63' and later panels look quite professional and are actually made to quite tight tolerances. A set of my rebuilt 63's is typically within a fraction of a dB to each other which says a lot about the panel precision. We have to be careful to judge pre-war manufacturing and materials of the 57's by modern standards. I'd say a more fair comparison is the DW's to the 63's.

Re mats31 post, the DW cells are rock-solid plastic moldings but easily mass produced. No reason ESLs shouldn't be easy to make cheap, aside from the fact that today, they have to interface with low output impedance amps and so need fancy transformers. Too bad.*

However wide bandwidth transformers are pretty easy to make (we've been doing it for 100 or so years now), so even that isn't too much of a hurdle. The big hurdle is ESL's size. Living rooms today don't support that sort of speaker size even though modern houses are enormous (at least here in the states)

Also there's the issue of high voltages and risk of lawsuits.

* making curved panels out of 6 DW cells is a swell configuration, like Janszen of yore; pity that DIY crowd tends to focus on single large (sometimes curved) cells rather than an array of easily fabricated small cells

Measuring something like that (soundlab comes to mind), can be a bit ugly due to the beaminess and comb filter effects. But in practice I suspect it would work just fine.

Sheldon

... I'm really impressed at how marginal they look yet how well they can work and how long they have lasted...

And speaking of "that" manufacturing mindset, a friend used to say about Land Rovers, "the same parts that broke first 50 years ago are the same ones that break first today".

Sad.

B.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Quad ESL 2805 or 2905 cloth replacement