I would add as an aside my esl63s continue to perform in exemplary fashion. Even when the 2905s are playing fine they seem a little strident and shouts compared to the 63s. Is it just me?

The guts of both speakers are effectively identical. There have been different types of passive components in the circuitry over the years. And the original clamp circuit was a bit different if your 63's are not the very latest revision. The speakers after the 63's use a grille which is perf-metal and is not as open as either of the 63 grilles. That could lead to a bit of a cavity resonance effect, but that would be a quite high frequencies.

So in general, I can't point to any one thing that could be causing the differences, but I can believe there is a difference.

I'm a big fan of the original 63's, they are cheap these days and to my eyes look the best. They blend into the surroundings better than 2805's or 2812's. The giant quads like the 2912's just CAN'T blend due to their insane size.

Sheldon

Holy crap! I think I worked it out. I hooked up a giant McCormack DNA 500 that I have just to check it out. I was surprised that it didn’t trigger any clamping, so I put on the songs that seem to make the speakers clamp predictably every time. Nada. Big fat dynamic orchestral pieces at huge volume.......nada.

Now the fact that the Quad Artera shuts down may be of interest. Is it possible the Artera is causing the speakers to clamp? It would explain everything, that fact that switching panels, the board did nothing. The amp shutting down.

Now the fact that the Quad Artera shuts down may be of interest. Is it possible the Artera is causing the speakers to clamp? It would explain everything, that fact that switching panels, the board did nothing. The amp shutting down.

Okay back to the topic of this thread. Distortion on one of my Quad 2805 speakers. Diagnosed as an activated clamp circuit. At first the most likely culprit seems to be a 1000 uF capacitor in the power supply. But replacement of the part didn't remedy the distortion.

Sheldon Stokes advised me to check the panels for possible fault conditions. I took the speaker apart and found one panel with a tiny tear in the membrane. I decided to replace the foil myself. After all It's all about diy here.

So I ordered the repair kit as offered by Eraudio in Australia. I quote from their website.

"The Quad 63 repair kit has been designed to address the most common issues found with faulty ESL panels, namely, low or distorted output from one or both speakers and strange noises such as hissing, clicking, popping etc. Our Quad 63 repair kit contains all you will need to rectify these problems. There are sufficient materials to repair a pair of speakers and have material left over. The repair is straightforward and requires normal handyman skills.¨

The kit is not exactly cheap but for a newb repairing his Esl worth every penny. Included in the kit are things like membrane adhesive, stator glue, membrane coating, spring balance for tensioning the foil, tensioning tape, copper tape, high voltage wire, Mylar film, dust cover material and much more. Accompanied by a comprehensive illustrated build guide. Another big plus is that Rob from Eraudio is a very friendly and helpful person. Questions by e-mail get a fast respons. This sounds like an advertisement but without the kit and instructions diy would be impossible for me.

How to dismantle the ESL can be seen in Quad 2805/2905 dismantling: in pictures (part 1) and Quad 2805/2905 dismantling: in pictures (part 2)

In the first picture below one of the panels is taken apart. One side carries the coated film, the other is covered by a fine mesh structure that is acting as damping.

Tensioning of the diaphragm is shown in the second picture. In the third picture fresh Mylar is glued to the stator.

I had serious problems when I had to make three holes in the Mylar where the central fixing bolts and post go through. The idea is to use a hot soldering iron, push it through the Mylar and move the iron in a circle to make the hole bigger by using the central posts as a guide. To be honest I made a mess of it.

So I had to "invent" something that would work for me. I took a metal ruler that I had lying around, drilled a hole of about 1 cm. See picture 4. Positioned the hole over the central post, heated up my hot air station with a nozzle that was an exact fit and pushed the hot nozzle through the Mylar. Easy peasy. But don't forget to switch off the hot air function before you come close to the Mylar. In fact you don't need a hot air station because a heated thin walled pipe of the right diameter will do.

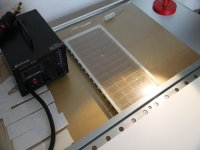

In the coating process part of the membrane is left free of coating. I made a mould to assist in the process. Picture 5.

When putting the panels together watch out for solder spatter to the membrane. In picture 6 I'm using aluminium foil as protection.

In the last picture the panels are back together and the wiring in place, sigh !

The ESL is sounding fine again but as the distortion problem is intermittent I'm not sure if it's really fixed. Time will tell. For now there is one question left. The blink rate of the neon bulb is about once a second. I noticed a somewhat higher blink rate when it was raining heavily. Is this ok ??

Sheldon Stokes advised me to check the panels for possible fault conditions. I took the speaker apart and found one panel with a tiny tear in the membrane. I decided to replace the foil myself. After all It's all about diy here.

So I ordered the repair kit as offered by Eraudio in Australia. I quote from their website.

"The Quad 63 repair kit has been designed to address the most common issues found with faulty ESL panels, namely, low or distorted output from one or both speakers and strange noises such as hissing, clicking, popping etc. Our Quad 63 repair kit contains all you will need to rectify these problems. There are sufficient materials to repair a pair of speakers and have material left over. The repair is straightforward and requires normal handyman skills.¨

The kit is not exactly cheap but for a newb repairing his Esl worth every penny. Included in the kit are things like membrane adhesive, stator glue, membrane coating, spring balance for tensioning the foil, tensioning tape, copper tape, high voltage wire, Mylar film, dust cover material and much more. Accompanied by a comprehensive illustrated build guide. Another big plus is that Rob from Eraudio is a very friendly and helpful person. Questions by e-mail get a fast respons. This sounds like an advertisement but without the kit and instructions diy would be impossible for me.

How to dismantle the ESL can be seen in Quad 2805/2905 dismantling: in pictures (part 1) and Quad 2805/2905 dismantling: in pictures (part 2)

In the first picture below one of the panels is taken apart. One side carries the coated film, the other is covered by a fine mesh structure that is acting as damping.

Tensioning of the diaphragm is shown in the second picture. In the third picture fresh Mylar is glued to the stator.

I had serious problems when I had to make three holes in the Mylar where the central fixing bolts and post go through. The idea is to use a hot soldering iron, push it through the Mylar and move the iron in a circle to make the hole bigger by using the central posts as a guide. To be honest I made a mess of it.

So I had to "invent" something that would work for me. I took a metal ruler that I had lying around, drilled a hole of about 1 cm. See picture 4. Positioned the hole over the central post, heated up my hot air station with a nozzle that was an exact fit and pushed the hot nozzle through the Mylar. Easy peasy. But don't forget to switch off the hot air function before you come close to the Mylar. In fact you don't need a hot air station because a heated thin walled pipe of the right diameter will do.

In the coating process part of the membrane is left free of coating. I made a mould to assist in the process. Picture 5.

When putting the panels together watch out for solder spatter to the membrane. In picture 6 I'm using aluminium foil as protection.

In the last picture the panels are back together and the wiring in place, sigh !

The ESL is sounding fine again but as the distortion problem is intermittent I'm not sure if it's really fixed. Time will tell. For now there is one question left. The blink rate of the neon bulb is about once a second. I noticed a somewhat higher blink rate when it was raining heavily. Is this ok ??

Attachments

Hi,

I have an issue with my ESL 63. One of the EHT modules was only 1,2Kv dc out (measured without being linked to the panels) both trafos are delivering 630 Vac so I decided to repopulate that module with new components. Vishay diodes GP 02-40, SR Passives 10n/3Kv capacitors, new Vishay resistors. After that, the output was only 3,6 Kv dc. I've switched the modules with the good one and the ht was 4,8 Kv dc I've switched the neon lamp module and was the same. There is anybody to help me with a clue?

I have an issue with my ESL 63. One of the EHT modules was only 1,2Kv dc out (measured without being linked to the panels) both trafos are delivering 630 Vac so I decided to repopulate that module with new components. Vishay diodes GP 02-40, SR Passives 10n/3Kv capacitors, new Vishay resistors. After that, the output was only 3,6 Kv dc. I've switched the modules with the good one and the ht was 4,8 Kv dc I've switched the neon lamp module and was the same. There is anybody to help me with a clue?

Right, it's flashing but the problem is the low HT after replacing the components.No you don’t need to. At the back side just behind the on/off switch there is a small rubber cap. When you remove the cap you can see the neon.

I started a new thread on the inductors to try to keep things organized.

Sheldon

Quad 63 (and later) Delay Line Inductors

For reference.

Ah, I should have said that I have 2805s. No rubber cap on these.No you don’t need to. At the back side just behind the on/off switch there is a small rubber cap. When you remove the cap you can see the neon.

To get access to the electronics of the 2805 and see the neon, look here:

Quad 2805/2905 dismantling: in pictures (part 1)

Quad 2805/2905 dismantling: in pictures (part 1)

The front grille needs removing to see the neon flashing, doesn't it?

That's one way. The other is to remove the cover on the "foot" at the back. The neon bulb is on the circuit board in the base.

Sheldon

I have just finished restoring all 4 panels on one of my 10 yr old 2805s. Every single stator had come away from the matrices. Quad had repanelled the other one 3 years ago. With an anxious heart I visited this site and others. This led me to Rob at Eraudio and I can endorse everything CLOG and Sheldon Stokes has said. Remarkable service. Endlessly patient with my queries and cries for help. The kit really does have all you need. Nerves shattered but very pleased with the result. But then a probable psu issue which got me to this thread and the wonderful info and tips from you all. Board cleaned and awaiting a few new components.

Great community!

Great community!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Quad 2805 power supply malfunction?