I did my first try at rebuilding a esl57 bass panel. I used double glazing window film and graphite. I tested it without dust covers and it played and was fine. The bolts i used were too long though so i swapped them all one by one with shorter ones. I refitted the dust covers, put the panel back in and although it plays, it has a slight hum. Its the only panel that hums so i want to sort it.

Im undecided what to do really. I might buy some proper mylar and some licron and do it again, or i might retry using the same technique as before. After all, it didnt hum at first. Im not sure whats happened.

My question is, what can cause hum? Im assuming its voltage leaking. I can maybe just hear a tiny crackle somewhere. It could just be some dust, or not quite being clean enough with the graphite powder. But can anyone give me a bit of rundown on what i can do to try and make sure it doesnt hum the second time? It doesnt seem to be leaking through the bolts to the dust cover frame, which is what i expected as i removed the dust covers again and it still hummed.

How important is the grey paint on the outside of the stator, as some came off when i removed the tape.

Also, what can i use to repair small sections of the silver tape inside? Little areas are damaged, i guessed it may not matter.

Thanks.

Im undecided what to do really. I might buy some proper mylar and some licron and do it again, or i might retry using the same technique as before. After all, it didnt hum at first. Im not sure whats happened.

My question is, what can cause hum? Im assuming its voltage leaking. I can maybe just hear a tiny crackle somewhere. It could just be some dust, or not quite being clean enough with the graphite powder. But can anyone give me a bit of rundown on what i can do to try and make sure it doesnt hum the second time? It doesnt seem to be leaking through the bolts to the dust cover frame, which is what i expected as i removed the dust covers again and it still hummed.

How important is the grey paint on the outside of the stator, as some came off when i removed the tape.

Also, what can i use to repair small sections of the silver tape inside? Little areas are damaged, i guessed it may not matter.

Thanks.

Small update on this. I took the panel apart again, couldnt see anything wrong really, small amount of dust maybe.

I took the diaphragm off, have cleaned up the stators again. I have repaired the aluminium tape around the outside and have stretched a new diaphragm. I will try again the same way as last time but be even more clinical about dust.

Last time i also put graphite on both sides of the diaphragm. Ive since read that graphite is a bit too conductive so maybe doing both sides was a mistake.

We'll see how this one works out.

I took the diaphragm off, have cleaned up the stators again. I have repaired the aluminium tape around the outside and have stretched a new diaphragm. I will try again the same way as last time but be even more clinical about dust.

Last time i also put graphite on both sides of the diaphragm. Ive since read that graphite is a bit too conductive so maybe doing both sides was a mistake.

We'll see how this one works out.

It does tend to get everywhere! I was pretty meticulous with the cleaning though. I didnt measure resistance, i will this time though. Im sure an internet search will tell me, but any tips on what measurement i should be looking for and best ways to test with a normal multimeter?

Too low a resistance will cause humming and occasionally sizzling sounds. The original ESL is a poor design in that the isolation from the power supply (and thus constant charge operation) is only done via the panel coating resistance. There isn't a series bias resistor in the design, so the resistance of the diaphragm coating plays more of a factor in proper panel operation than the later designs. So your humming is likely too low a resistance. Graphite is tricky to make work correctly on those speakers, it take s a bit of finesse. you may want to get a better high resistance coating, then you'd be fine.

Sheldon

quadesl.com

Sheldon

quadesl.com

Hi,

My suggestion is not to use graphite.

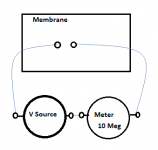

Surface resistance could be measured by using a common multimeter, for which input impedance is known(e.g 10 MOhm). Then you need to place a couple of coins on the membrane for contact with multimeter leads and in series with let's say 9V battery in such a way that voltage is divided amongst multimeter and resistance of the coating. Then you can read DC voltage on multimeter and recalculate ratio of voltage and impedance.

It may not be especially accurate but IMO good enough. Anything below 1e+8 ohms is low for this speaker; perhaps you should be considering in order of 1e+9 or more.

Regards

My suggestion is not to use graphite.

Surface resistance could be measured by using a common multimeter, for which input impedance is known(e.g 10 MOhm). Then you need to place a couple of coins on the membrane for contact with multimeter leads and in series with let's say 9V battery in such a way that voltage is divided amongst multimeter and resistance of the coating. Then you can read DC voltage on multimeter and recalculate ratio of voltage and impedance.

It may not be especially accurate but IMO good enough. Anything below 1e+8 ohms is low for this speaker; perhaps you should be considering in order of 1e+9 or more.

Regards

Im not sure that makes much sense to me, ill re read it a few times.

Once i have the measurement, how do i do the calculation?

Hi,

Attached a picture. Voltage is divided amongst input impedance of multimeter and measured resistance. So e.g if voltmeter reads 1V with 10V source it can be roughly estimated that resistance of coating may be in the range of ~10x of multimeter. Keep in mind that it's very important to have good contact between membrane and measurement points(large area, clean etc). This method is sort of rough but IMO good enough to get an idea about surface resistance.

Regards,

Lukas.

Attachments

Hi,

Attached a picture. Voltage is divided amongst input impedance of multimeter and measured resistance. So e.g if voltmeter reads 1V with 10V source it can be roughly estimated that resistance of coating may be in the range of ~10x of multimeter. Keep in mind that it's very important to have good contact between membrane and measurement points(large area, clean etc). This method is sort of rough but IMO good enough to get an idea about surface resistance.

Regards,

Lukas.

Thanks, i understand now.

Ive found a new coating, statclear a50, will be next week till it arrives though, but this panel is on hold till it arrives. No point using graphite again when i have a better option on the way.

Hi,

It's always interesting to hear about inexpensive and reliable coatings. From my experience there are only a few.

I have contacted the company about resistance to sunlight and they replied it has been tested under exposure for a couple of years.

If also the resistance does not very by humudity by much, it's even more interesting.

Regards,

Lukas.

Hi,

It's always interesting to hear about inexpensive and reliable coatings. From my experience there are only a few.

I have contacted the company about resistance to sunlight and they replied it has been tested under exposure for a couple of years.

If also the resistance does not very by humudity by much, it's even more interesting.

Regards,

Lukas.

Yes, it seems good. I will find out soon enough. They were kind enough yo give me a free sample too.

I rebuilt this panel. I made sure the stators were spotless, repaired the perimeter foil tape, made a new diaphragm and used the statclear coating.

I just tried it and it still hums and still has a slight sizzle from one corner of the panel.

I didnt measure the surface resistance, but looks like this panel might be coming apart again anyway.

Apart from maybe coating type, i dont see what else i can do differently.

One thing i did notice, dont know if this is just to be expected, but if i disconnect the stators and just leave power to the diaphragm it doesnt hum.

I just tried it and it still hums and still has a slight sizzle from one corner of the panel.

I didnt measure the surface resistance, but looks like this panel might be coming apart again anyway.

Apart from maybe coating type, i dont see what else i can do differently.

One thing i did notice, dont know if this is just to be expected, but if i disconnect the stators and just leave power to the diaphragm it doesnt hum.

The hum and sizzle could be not enough diaphragm tension and the diaphragm is collapsing against a stator.

If you only hook up the high voltage wire, you aren't completing the circuit, the high voltage is references to the center of the transformer winding that is connecting the stators.

Sheldon

If you only hook up the high voltage wire, you aren't completing the circuit, the high voltage is references to the center of the transformer winding that is connecting the stators.

Sheldon

The hum and sizzle could be not enough diaphragm tension and the diaphragm is collapsing against a stator.

If you only hook up the high voltage wire, you aren't completing the circuit, the high voltage is references to the center of the transformer winding that is connecting the stators.

Sheldon

Thanks.

I thought that might be the case with not connecting the stators. The noise starts and stops instantly on removing the power cord. I dont have the dust covers on so i can see the diaphragm, i dont think its collapsing onto the stator.

The sizzle is quiet, i have to have my ear close to the panel to hear it, the hum is audible from a meter away. I did notice the other bass panel also has a slight hum. This panel is original. It is quieter though and not enough to cause me concern.

I used window secondary glazing film for the diaphragm as it was all i could find. I have ordered some mylar now though so redoing it again is an option.

Ill try and measure coating resistance tomorrow and see if it could still be the issue.

Im starting to get a little frustrated with it, but im sure ill get it sorted in the end.

Could it be a power supply problem, or do you think its definitely the panel? I might try swapping the power supplies between speakers and see if the fault follows.

I guess the sizzle is quite a big clue its still a panel problem, but its also possible there is more than one issue. The power supplies have new caps, diodes and resistors though.

Last edited:

Hi,

Try to disconnect the panel you rebuilt. Does the original panel still produces hum ?

If not, then also second test to confirm :

Does the speaker still play music if disconnected from the wall, with rebuilt panel connected and disconnected ?

If the output drops immediately in any case, you most likely have a problem with HV polarizing voltage leaking from membrane to stator(s). Previously you did it with graphite. A finger print of graphite in a wrong place is sometimes more than enough to cause sufficient loading on HV supply and quick voltage drops, exposing ripple of the supply.

A membrane that has collapsed to a stator because of low tension often produces cracking noises when polarizing voltage is removed.

Regards,

Lukas.

Try to disconnect the panel you rebuilt. Does the original panel still produces hum ?

If not, then also second test to confirm :

Does the speaker still play music if disconnected from the wall, with rebuilt panel connected and disconnected ?

If the output drops immediately in any case, you most likely have a problem with HV polarizing voltage leaking from membrane to stator(s). Previously you did it with graphite. A finger print of graphite in a wrong place is sometimes more than enough to cause sufficient loading on HV supply and quick voltage drops, exposing ripple of the supply.

A membrane that has collapsed to a stator because of low tension often produces cracking noises when polarizing voltage is removed.

Regards,

Lukas.

Hi,

Try to disconnect the panel you rebuilt. Does the original panel still produces hum ?

If not, then also second test to confirm :

Does the speaker still play music if disconnected from the wall, with rebuilt panel connected and disconnected ?

If the output drops immediately in any case, you most likely have a problem with HV polarizing voltage leaking from membrane to stator(s). Previously you did it with graphite. A finger print of graphite in a wrong place is sometimes more than enough to cause sufficient loading on HV supply and quick voltage drops, exposing ripple of the supply.

A membrane that has collapsed to a stator because of low tension often produces cracking noises when polarizing voltage is removed.

Regards,

Lukas.

Thanks, just tried all these.

Original panel has same hum with rebuilt one disconnected. It is very faint though.

Speaker plays for ages with no power input. 10 seconds of charge and speaker will play for at least 15 -20 mins, i gave up after that and turned the record off.

The rebuilt panel drops volume quickly though. The hum stops the second you pull the power, the sizzle fades out over a couple of seconds and the music fades out over 10 seconds or so. Seems it has a leak, doesnt seem to be pulling the other panels down much though, not the treble panel anyway. I think the original bass panel may be a touch quiet.

So, there is voltage leak on the rebuilt panel, i just need to work out why. I will open it up, check for dirt, measure the diaphragm resistance and take some photos.

Hopefully i have managed to add some pics.

The area where the sizzle is does have a couple of marks, could be enough?

Diaphragm tension doesnt really seem to be as high as i aimed for. I have no real way of measuring it but an AA battery on end does not make the diaphragm contact the stator. It wouldnt take much more though. Too low a tension? I guess if its getting pulled too close to the stator it would be easier for voltage to leak via any marks?

The area where the sizzle is does have a couple of marks, could be enough?

Diaphragm tension doesnt really seem to be as high as i aimed for. I have no real way of measuring it but an AA battery on end does not make the diaphragm contact the stator. It wouldnt take much more though. Too low a tension? I guess if its getting pulled too close to the stator it would be easier for voltage to leak via any marks?

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- ESL57 rebuilt panel hum