Hello everyone! I’ve been a long time reader of this forum but I finally decided to join as I need help with a new project. I’ve built two kits (a power amp and a phono pre amp) from Tubes4hifi.com so I have a bit of experience in the DIY aspect of electronics but I’m really interested in building an electrostatic speaker.

If someone could direct me to a kit where I could build such a speaker that would be marvelous but if no such kit exists then I would love as many resources as I get to learn how to build one from scratch.

If I go down the route of building it from scratch I think I will start will a small prototype/model just to see if I can even get a such speaker to work. Then try and contruct a full size “monster.”

If someone could direct me to a kit where I could build such a speaker that would be marvelous but if no such kit exists then I would love as many resources as I get to learn how to build one from scratch.

If I go down the route of building it from scratch I think I will start will a small prototype/model just to see if I can even get a such speaker to work. Then try and contruct a full size “monster.”

You can try here Electrostatic Loudspeakers By ER Audio They have a kits as well as parts

I've not tried ER Audio's kit designs, but I have used Rob's materials before and after knowing him and talking to him a lot, he knows what he's doing. I'd expect his designs to be solid. The real question is: Are his designs along the lines of what you want to build?

Sheldon

Sheldon

I will start will a small prototype/model just to see if I can even get a such

speaker to work. Then try and contruct a full size “monster.”

Don't try to build an electrostatic woofer. It won't fly, and the rest of the range will be poor.

If you should also be interested in the theory behind electrostatic loudspeakers, I highly recommend this site: Elektrostatic Loudspeakers

(For example, it explains why voltage-driven flat-panel electrostatic loudspeakers have a poor frequency response, especially in the bass, and how to solve that.)

(For example, it explains why voltage-driven flat-panel electrostatic loudspeakers have a poor frequency response, especially in the bass, and how to solve that.)

Last edited:

I've not tried ER Audio's kit designs, but I have used Rob's materials before and after knowing him and talking to him a lot, he knows what he's doing. I'd expect his designs to be solid. The real question is: Are his designs along the lines of what you want to build?

Sheldon

Well if such kits exists it looks like a really good start for a newcomer (to speakers at least.) Has anyone on here have experience with these kits?

Just go down to your local hardware store and get the materials and start building !!!

Except for the Licron Crystal coating that I use my ESL's diaphragm's cost less than a me're 5$ or even less to build for a pair of panels.

Except for the larger Perforated Metal design, the can be rather costly, and, Quite frankly have a terrible horizontal frequency dispersion !!

I suggest to stick with Electrically Segmented designs for large panels.

For many more reasons and design criteria, They are found in many detailed threads in this forum.

I had thought about presenting these in a kit form as I have just a few more very small details to work out, But I don't have the ample time required for proper full customer support.

However the electronics required to drive them can be had for under $100 or so, if you are frugal.

Cheers !!!

jer

Except for the Licron Crystal coating that I use my ESL's diaphragm's cost less than a me're 5$ or even less to build for a pair of panels.

Except for the larger Perforated Metal design, the can be rather costly, and, Quite frankly have a terrible horizontal frequency dispersion !!

I suggest to stick with Electrically Segmented designs for large panels.

For many more reasons and design criteria, They are found in many detailed threads in this forum.

I had thought about presenting these in a kit form as I have just a few more very small details to work out, But I don't have the ample time required for proper full customer support.

However the electronics required to drive them can be had for under $100 or so, if you are frugal.

Cheers !!!

jer

Attachments

-

S1.jpg76 KB · Views: 238

S1.jpg76 KB · Views: 238 -

Desktop ESL.jpg74.7 KB · Views: 245

Desktop ESL.jpg74.7 KB · Views: 245 -

ESL and Woofer.jpg101.3 KB · Views: 247

ESL and Woofer.jpg101.3 KB · Views: 247 -

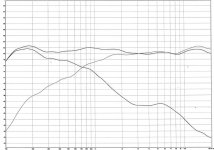

Raw.jpg130.1 KB · Views: 233

Raw.jpg130.1 KB · Views: 233 -

Octave smoothing.jpg124 KB · Views: 234

Octave smoothing.jpg124 KB · Views: 234 -

three panel setup.jpg55.7 KB · Views: 83

three panel setup.jpg55.7 KB · Views: 83 -

Ready for The Diaphragm.jpg168.3 KB · Views: 96

Ready for The Diaphragm.jpg168.3 KB · Views: 96 -

P1010231.jpg697.9 KB · Views: 109

P1010231.jpg697.9 KB · Views: 109

Last edited:

I had thought about presenting these in a kit form as I have just a few more very small details to work out, But I don't have the ample time required for proper full customer support.

Jer, your kits would be the answer for many of us! You should solicit some crowd-sourced customer support from some of us diyaudio members...

Well, It is something that I am still considering in the long run though, Thanks !!

Using scavenged plastic frames - like the protective covers from fluorescent ceiling luminaires - jet-propels the construction process and makes selling kits far simpler.

Or.... 3D printing (gosh, if I were young again, I'd sure have one in my shop). Makes no sense anymore to build tricky ESL frames when you could just "print" exactly what you need.

Seems really helpful to use ready-to-go mechanicals along with film and coatings that are much more easily sourced in quantity by a kit maker. All the pieces are a pain for individuals to access but easy for an experienced guy like Gerald.

Likewise for the electrical bits although they are easy enough for a single buyer to order.

B.

Last edited:

Hi There, Been busy, I hope everyone had a Safe Holiday !!!

A 3D printed frame is in the works for my Desktop version, I just gotta wrap my head around Fusion 360 for a bit.

I am not too crazy about using PLA, I think that it is a bit soft as it flex's easily, although it would work.

I am going to order up some ABS and Graphite filled filament and give it a try and once I learn Fusion 360 I have a Ton of ideas that I want to try, Including rubber surrounds !!!

I just wanted to state that I have said ESL's are easy to build !!

I know that I have been corrected several times for that statement but if you have the skills to build models of any kind (IE~Balsa wood airplanes and such) then you possess the the skills to accomplish the required tasks at hand.

I spent the better half of 20 years from 1983-2003 just reading everything I could find on them and stumbled on a source of Mylar in 1993 in the back page ad's of Popular Mechanics, but, I didn't build my first set until 2003 and those are the ones that I have been posting about all these years.

Once I made my plan of attack I then took the plunge with surprising results a couple of months later (April to June of 2003), during that time I tried every type of material to work with for Diaphragms,Stator's and coatings.

I was unemployed at the time so I had to be super frugal and spent about $200 in various materials just to find out that $20-$40 was more than enough for what I was trying accomplish as perforated metal was out of the question due to the cost!

Alro Steel is just down the street from me so availability and shipping was not even an issue.

I don't believe in building a large panel for a First Time Build, the cost in materials is too great if something does not go right when you have to start all over from scratch !!

Nor do I prefer or advise to use that type of construction any more, especially for a large panel.

I have seen this happen in these threads many many times, and those of whom that have succeeded following the guidelines that we have set out in this forum, Usually, are so blown away with what they have created that they are very content and you never hear from them again !!! ...... Hmmmmmmm......

All of the complaints I have read about Small ESL's don't perform well..........

Well that is Utter BS, and I had set out to prove that theory wrong and succeeded to do so.

You just have to plan it out correctly and balance the system accordingly.

For example one DIYer in these threads made a 4-6" x 24-36" panel and paired it with a single 6 1/2" or 8" woofer and complained about it being inefficient and thin sounding.

Well it was a Beautiful build but the design was not properly planned out ahead of time.

Building smaller panels, First Off, Allows you to acquire and polish those skills, they are easier to handle on you workbench, and is a very small investment should you need to build a new one for whatever reason, as I have done many times over.

Actually I have only made 5 or 6 set's of stator's total, since 2003, but I have replaced the diaphragms several times for each setup for various reasons of testing and R&D.

So by now, All of the foot work has been laid out as to what works and what doesn't for the most part.

The Incredible results I got out of all of that allows me to go on and build a huge full size system knowing that it will work right of the batt !!

Here is the list of materials that I have had success with, but, I am not going to include the electronic components, that is a whole another thread and has been gone over over many times.

The Diaphragm:

First and Foremost, "Don't Waste Your Time with Anything Else but Mylar" , unless of course you just want to experiment.

I have considered Kapton for some Car Audio builds, but it is expensive and a very strong frame and mechanical stretching is required to use it as it Does Not Shrink with Heat.

I have even used Monokote and Ultrakote with great results as well only that it is a bit thicker than the mostly preferred .25-.5mil of thickness for the film.

I measured about .66-.75 mil of thickness for the Ultrakote after I washed off all of the extra heat glue backing with some acetone once they were mounted and about 1-1.5mil for Monokote.

For the coatings there are several options available from Graphite (not recommended anymore) to many forms of liquid Staticides that are a available.

I use Licron (not made anymore), "Crystal" is the new formula of Licron.

I it is not cheap but I have used it since It First hit the market while was building my very First panels in 2003.

It has never failed me as coating and the diaphragms I made all those years ago still work to this day.

Most of which are un-usable due to holes burn't in them or have been torn.

For the Stators:

You can get by with perforated metal for smaller widths up to about 4" and a maximum of 6" (even this is still to wide), anything wider your gonna have a very very narrow sweet spot and it won't be enjoyable to try to listen to.

The Cheapest stator material I have success with was with some Common Aluminium (can't find steel anymore) Window Screen !!!

My Favorite material to use now is TIG rod !!!

I started with some .0625" stuff but now I have switched to the thinner .045" version and the .035" I have not tried yet as it seems also to me that it is to thin and has no structural integrity for the most part.

The thinner the rod the harder it is to have perfectly straight pieces.

For Stator Coatings I have a whole thread on that with some photos and test results !!

Believe it or not no special formula here, Spray Bombs you find on the shelf at your local hardware store.

That link is here,

High strength Dielectric Coatings, fact or fiction

For my Highest Performing panels I had used Window screen that I had Double Powder Coated.

Those turned out fabulous but not without much trial and error !!

I plan on refining that method for the average DIY'er sometime in the future, as I was quite impressed with the results when I first built them until there final demise.

The results of those panels were Astounding !!!

Unbelievable Really !!!

My descriptions of those things are for Real!!

I am not in this game to tell any tall tails, they Truly surpassed my expectations as what could be done with a rather small panel with just 3.75" x 9.5" diaphragm size !!!

In due time I will start a new thread on building and testing the original design in order to show that "Yes" the results Can Be Duplicated but with more reliability.

And also it will be done using a DIY method of Powder Coating this time around as it has its issues that still need to be worked out.

Next is PVC coated hookup wire, this is a preferred method by many but its construction method can become quite involved when it come to getting the wires perfectly straight not to mention gluing them down properly to the stator frames, not to mention the cost of a large spool of it.

It offers absolutely No structural integrity what so ever, as this is why I prefer to use TIG rod now.

However it is a proven tried and tested material to use and can almost guarantee a decent build with it, but much harder to work with.

You will spend more money and time on your Stretching/Building jig than you will on the two panels that you are creating !!

I build mine simply on a piece of glass on my desktop.

Next is your Glues required for the materials you chose, pretty simple here,

Some like to use double side tape to mount the Mylar with.

I have not used this method yet, it is an easy method yet not so easy should you have to re-do your diaphragm, and sometimes even it can fail leaving you with a rattling membrane or one that losses tension. :/

I prefer to use a good epoxy.

Yes, It Is Messy but I have found it holds the best and if you need to re-do it, it peels right off of the frames very cleanly with a razor blade and just re-apply the new epoxy and diaphragm and your done !!!

After you do this a few times it becomes second nature after that.

Some Acrylic and Acrylic solvent and in my case, Some Lighting Grates from Home Depot for about $12 for th basic frame to mount the Window Screen material.

For TIG rod's I just use some PCB for the rods to be soldered to and the rest was done with Acrylic strips.

Some .020-.040 " Mylar sheets or polystyrene or something like it comes in handy as well !!

And of course Spray Paint !!!! He,he,he,he

Well, I think I am approaching the 5000 character limit for this post, but I hope that this info will help to get you inspired to start building ESL's, Trust me it is all worth it !!!

Enjoy and Good luck and...........

Keep On DIY'ing !!!

Cheers !!!

jer

A 3D printed frame is in the works for my Desktop version, I just gotta wrap my head around Fusion 360 for a bit.

I am not too crazy about using PLA, I think that it is a bit soft as it flex's easily, although it would work.

I am going to order up some ABS and Graphite filled filament and give it a try and once I learn Fusion 360 I have a Ton of ideas that I want to try, Including rubber surrounds !!!

I just wanted to state that I have said ESL's are easy to build !!

I know that I have been corrected several times for that statement but if you have the skills to build models of any kind (IE~Balsa wood airplanes and such) then you possess the the skills to accomplish the required tasks at hand.

I spent the better half of 20 years from 1983-2003 just reading everything I could find on them and stumbled on a source of Mylar in 1993 in the back page ad's of Popular Mechanics, but, I didn't build my first set until 2003 and those are the ones that I have been posting about all these years.

Once I made my plan of attack I then took the plunge with surprising results a couple of months later (April to June of 2003), during that time I tried every type of material to work with for Diaphragms,Stator's and coatings.

I was unemployed at the time so I had to be super frugal and spent about $200 in various materials just to find out that $20-$40 was more than enough for what I was trying accomplish as perforated metal was out of the question due to the cost!

Alro Steel is just down the street from me so availability and shipping was not even an issue.

I don't believe in building a large panel for a First Time Build, the cost in materials is too great if something does not go right when you have to start all over from scratch !!

Nor do I prefer or advise to use that type of construction any more, especially for a large panel.

I have seen this happen in these threads many many times, and those of whom that have succeeded following the guidelines that we have set out in this forum, Usually, are so blown away with what they have created that they are very content and you never hear from them again !!! ...... Hmmmmmmm......

All of the complaints I have read about Small ESL's don't perform well..........

Well that is Utter BS, and I had set out to prove that theory wrong and succeeded to do so.

You just have to plan it out correctly and balance the system accordingly.

For example one DIYer in these threads made a 4-6" x 24-36" panel and paired it with a single 6 1/2" or 8" woofer and complained about it being inefficient and thin sounding.

Well it was a Beautiful build but the design was not properly planned out ahead of time.

Building smaller panels, First Off, Allows you to acquire and polish those skills, they are easier to handle on you workbench, and is a very small investment should you need to build a new one for whatever reason, as I have done many times over.

Actually I have only made 5 or 6 set's of stator's total, since 2003, but I have replaced the diaphragms several times for each setup for various reasons of testing and R&D.

So by now, All of the foot work has been laid out as to what works and what doesn't for the most part.

The Incredible results I got out of all of that allows me to go on and build a huge full size system knowing that it will work right of the batt !!

Here is the list of materials that I have had success with, but, I am not going to include the electronic components, that is a whole another thread and has been gone over over many times.

The Diaphragm:

First and Foremost, "Don't Waste Your Time with Anything Else but Mylar" , unless of course you just want to experiment.

I have considered Kapton for some Car Audio builds, but it is expensive and a very strong frame and mechanical stretching is required to use it as it Does Not Shrink with Heat.

I have even used Monokote and Ultrakote with great results as well only that it is a bit thicker than the mostly preferred .25-.5mil of thickness for the film.

I measured about .66-.75 mil of thickness for the Ultrakote after I washed off all of the extra heat glue backing with some acetone once they were mounted and about 1-1.5mil for Monokote.

For the coatings there are several options available from Graphite (not recommended anymore) to many forms of liquid Staticides that are a available.

I use Licron (not made anymore), "Crystal" is the new formula of Licron.

I it is not cheap but I have used it since It First hit the market while was building my very First panels in 2003.

It has never failed me as coating and the diaphragms I made all those years ago still work to this day.

Most of which are un-usable due to holes burn't in them or have been torn.

For the Stators:

You can get by with perforated metal for smaller widths up to about 4" and a maximum of 6" (even this is still to wide), anything wider your gonna have a very very narrow sweet spot and it won't be enjoyable to try to listen to.

The Cheapest stator material I have success with was with some Common Aluminium (can't find steel anymore) Window Screen !!!

My Favorite material to use now is TIG rod !!!

I started with some .0625" stuff but now I have switched to the thinner .045" version and the .035" I have not tried yet as it seems also to me that it is to thin and has no structural integrity for the most part.

The thinner the rod the harder it is to have perfectly straight pieces.

For Stator Coatings I have a whole thread on that with some photos and test results !!

Believe it or not no special formula here, Spray Bombs you find on the shelf at your local hardware store.

That link is here,

High strength Dielectric Coatings, fact or fiction

For my Highest Performing panels I had used Window screen that I had Double Powder Coated.

Those turned out fabulous but not without much trial and error !!

I plan on refining that method for the average DIY'er sometime in the future, as I was quite impressed with the results when I first built them until there final demise.

The results of those panels were Astounding !!!

Unbelievable Really !!!

My descriptions of those things are for Real!!

I am not in this game to tell any tall tails, they Truly surpassed my expectations as what could be done with a rather small panel with just 3.75" x 9.5" diaphragm size !!!

In due time I will start a new thread on building and testing the original design in order to show that "Yes" the results Can Be Duplicated but with more reliability.

And also it will be done using a DIY method of Powder Coating this time around as it has its issues that still need to be worked out.

Next is PVC coated hookup wire, this is a preferred method by many but its construction method can become quite involved when it come to getting the wires perfectly straight not to mention gluing them down properly to the stator frames, not to mention the cost of a large spool of it.

It offers absolutely No structural integrity what so ever, as this is why I prefer to use TIG rod now.

However it is a proven tried and tested material to use and can almost guarantee a decent build with it, but much harder to work with.

You will spend more money and time on your Stretching/Building jig than you will on the two panels that you are creating !!

I build mine simply on a piece of glass on my desktop.

Next is your Glues required for the materials you chose, pretty simple here,

Some like to use double side tape to mount the Mylar with.

I have not used this method yet, it is an easy method yet not so easy should you have to re-do your diaphragm, and sometimes even it can fail leaving you with a rattling membrane or one that losses tension. :/

I prefer to use a good epoxy.

Yes, It Is Messy but I have found it holds the best and if you need to re-do it, it peels right off of the frames very cleanly with a razor blade and just re-apply the new epoxy and diaphragm and your done !!!

After you do this a few times it becomes second nature after that.

Some Acrylic and Acrylic solvent and in my case, Some Lighting Grates from Home Depot for about $12 for th basic frame to mount the Window Screen material.

For TIG rod's I just use some PCB for the rods to be soldered to and the rest was done with Acrylic strips.

Some .020-.040 " Mylar sheets or polystyrene or something like it comes in handy as well !!

And of course Spray Paint !!!! He,he,he,he

Well, I think I am approaching the 5000 character limit for this post, but I hope that this info will help to get you inspired to start building ESL's, Trust me it is all worth it !!!

Enjoy and Good luck and...........

Keep On DIY'ing !!!

Cheers !!!

jer

Last edited:

Hi There, Been busy, I hope everyone had a Safe Holiday !!!

A 3D printed frame is in the works for my Desktop version, I just gotta wrap my head around Fusion 360 for a bit.

I am not too crazy about using PLA, I think that it is a bit soft as it flex's easily, although it would work.

I am going to order up some ABS and Graphite filled filament and give it a try and once I learn Fusion 360 I have a Ton of ideas that I want to try, Including rubber surrounds !!!

I just wanted to state that I have said ESL's are easy to build !!

I know that I have been corrected several times for that statement but if you have the skills to build models of any kind (IE~Balsa wood airplanes and such) then you possess the the skills to accomplish the required tasks at hand.

I spent the better half of 20 years from 1983-2003 just reading everything I could find on them and stumbled on a source of Mylar in 1993 in the back page ad's of Popular Mechanics, but, I didn't build my first set until 2003 and those are the ones that I have been posting about all these years.

Once I made my plan of attack I then took the plunge with surprising results a couple of months later (April to June of 2003), during that time I tried every type of material to work with for Diaphragms,Stator's and coatings.

I was unemployed at the time so I had to be super frugal and spent about $200 in various materials just to find out that $20-$40 was more than enough for what I was trying accomplish as perforated metal was out of the question due to the cost!

Alro Steel is just down the street from me so availability and shipping was not even an issue.

I don't believe in building a large panel for a First Time Build, the cost in materials is too great if something does not go right when you have to start all over from scratch !!

Nor do I prefer or advise to use that type of construction any more, especially for a large panel.

I have seen this happen in these threads many many times, and those of whom that have succeeded following the guidelines that we have set out in this forum, Usually, are so blown away with what they have created that they are very content and you never hear from them again !!! ...... Hmmmmmmm......

All of the complaints I have read about Small ESL's don't perform well..........

Well that is Utter BS, and I had set out to prove that theory wrong and succeeded to do so.

You just have to plan it out correctly and balance the system accordingly.

For example one DIYer in these threads made a 4-6" x 24-36" panel and paired it with a single 6 1/2" or 8" woofer and complained about it being inefficient and thin sounding.

Well it was a Beautiful build but the design was not properly planned out ahead of time.

Building smaller panels, First Off, Allows you to acquire and polish those skills, they are easier to handle on you workbench, and is a very small investment should you need to build a new one for whatever reason, as I have done many times over.

Actually I have only made 5 or 6 set's of stator's total, since 2003, but I have replaced the diaphragms several times for each setup for various reasons of testing and R&D.

So by now, All of the foot work has been laid out as to what works and what doesn't for the most part.

The Incredible results I got out of all of that allows me to go on and build a huge full size system knowing that it will work right of the batt !!

Here is the list of materials that I have had success with, but, I am not going to include the electronic components, that is a whole another thread and has been gone over over many times.

The Diaphragm:

First and Foremost, "Don't Waste Your Time with Anything Else but Mylar" , unless of course you just want to experiment.

I have considered Kapton for some Car Audio builds, but it is expensive and a very strong frame and mechanical stretching is required to use it as it Does Not Shrink with Heat.

I have even used Monokote and Ultrakote with great results as well only that it is a bit thicker than the mostly preferred .25-.5mil of thickness for the film.

I measured about .66-.75 mil of thickness for the Ultrakote after I washed off all of the extra heat glue backing with some acetone once they were mounted and about 1-1.5mil for Monokote.

For the coatings there are several options available from Graphite (not recommended anymore) to many forms of liquid Staticides that are a available.

I use Licron (not made anymore), "Crystal" is the new formula of Licron.

I it is not cheap but I have used it since It First hit the market while was building my very First panels in 2003.

It has never failed me as coating and the diaphragms I made all those years ago still work to this day.

Most of which are un-usable due to holes burn't in them or have been torn.

For the Stators:

You can get by with perforated metal for smaller widths up to about 4" and a maximum of 6" (even this is still to wide), anything wider your gonna have a very very narrow sweet spot and it won't be enjoyable to try to listen to.

The Cheapest stator material I have success with was with some Common Aluminium (can't find steel anymore) Window Screen !!!

My Favorite material to use now is TIG rod !!!

I started with some .0625" stuff but now I have switched to the thinner .045" version and the .035" I have not tried yet as it seems also to me that it is to thin and has no structural integrity for the most part.

The thinner the rod the harder it is to have perfectly straight pieces.

For Stator Coatings I have a whole thread on that with some photos and test results !!

Believe it or not no special formula here, Spray Bombs you find on the shelf at your local hardware store.

That link is here,

High strength Dielectric Coatings, fact or fiction

For my Highest Performing panels I had used Window screen that I had Double Powder Coated.

Those turned out fabulous but not without much trial and error !!

I plan on refining that method for the average DIY'er sometime in the future, as I was quite impressed with the results when I first built them until there final demise.

The results of those panels were Astounding !!!

Unbelievable Really !!!

My descriptions of those things are for Real!!

I am not in this game to tell any tall tails, they Truly surpassed my expectations as what could be done with a rather small panel with just 3.75" x 9.5" diaphragm size !!!

In due time I will start a new thread on building and testing the original design in order to show that "Yes" the results Can Be Duplicated but with more reliability.

And also it will be done using a DIY method of Powder Coating this time around as it has its issues that still need to be worked out.

Next is PVC coated hookup wire, this is a preferred method by many but its construction method can become quite involved when it come to getting the wires perfectly straight not to mention gluing them down properly to the stator frames, not to mention the cost of a large spool of it.

It offers absolutely No structural integrity what so ever, as this is why I prefer to use TIG rod now.

However it is a proven tried and tested material to use and can almost guarantee a decent build with it, but much harder to work with.

You will spend more money and time on your Stretching/Building jig than you will on the two panels that you are creating !!

I build mine simply on a piece of glass on my desktop.

Next is your Glues required for the materials you chose, pretty simple here,

Some like to use double side tape to mount the Mylar with.

I have not used this method yet, it is an easy method yet not so easy should you have to re-do your diaphragm, and sometimes even it can fail leaving you with a rattling membrane or one that losses tension. :/

I prefer to use a good epoxy.

Yes, It Is Messy but I have found it holds the best and if you need to re-do it, it peels right off of the frames very cleanly with a razor blade and just re-apply the new epoxy and diaphragm and your done !!!

After you do this a few times it becomes second nature after that.

Some Acrylic and Acrylic solvent and in my case, Some Lighting Grates from Home Depot for about $12 for th basic frame to mount the Window Screen material.

For TIG rod's I just use some PCB for the rods to be soldered to and the rest was done with Acrylic strips.

Some .020-.040 " Mylar sheets or polystyrene or something like it comes in handy as well !!

And of course Spray Paint !!!! He,he,he,he

Well, I think I am approaching the 5000 character limit for this post, but I hope that this info will help to get you inspired to start building ESL's, Trust me it is all worth it !!!

Enjoy and Good luck and...........

Keep On DIY'ing !!!

Cheers !!!

jer

Wow!!! Thank you very much for such an awesome reply! I am very inspired by your post (and other projects i’ve seem) that I have decided to start building my first prototypes. They will be planar magnetics. Why? Because planars can be driven like regular speakers and do not need special electronics to work. Eventually I will try and build some ESL’s but that might require learning some electrical engineering...so I will hold off for now. Clearly you are pleased with the results and enjoy the process so I probably will as well. Have you tried planars before? How do they sound compared to ESL’s?

Awesome, Your decision is quite understandable.

I wanted to build a set of magi's but I have a lot of tape equipment, so I didn't want any strong magnetic fields in their vicinity..... At All !!

That is the main reason I chose to go with ESL's, Besides the fact that I have been obsessed with ESL's since I was in Grade School after reading about the 57's in an issue of Popular mechanics in the mid 70's.

However I do have a very aging set of Apogee Duette's, and the first time I had heard them ...... I was blown away !!!

Then I discovered Roger Sanders and David P. Hermeyer's build's in 84 the 1980 Audio Amateur Handbook, and that was what got me going.

As far as the sound, the Apogee's were Top Notch and I could not believe what I was hearing.

Then as I was starting building mine I manged to find a set of Martin Logan ESL's in a local shop just to listen too and just to find out what I was up against and what to expect.....Again was blown away !!!

But when I got my panels done I found that the sound was a bit more detailed than what I was used to listening to with my Apogee's in the 90's and that was without having a woofer to fill in the bottom end.

My Friend Dave, whom I ran my recording studio with, liked them a lot, but he is impartial to the Duette's only because my setup didn't have a woofer for the low end, this is understandable as well but he did notice the amount of detail that they could pullout.

In Fact IMHO it seemed that there was too much detail (He,he,he) and I found it difficult to listen to such classics such as PinkFlyod's "Dark Side of the Moon" or Peter Frampton's " Comes Alive" albums and with no low end to fill everything in you could hear every single edit and splice that was made during the creation process of the recording and that was off of old Vinyl Records !!!

Also stereo imaging was much better than what I heard from the ML's, I am saying this with a very unbiased observation.

Just because I made them doesn't mean that they sounded better, But, They really did sound much clearer to me ignoring the fact that they had no low end because I had not added a woofer yet.

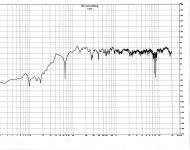

7 years later when I got them back out and running again, finally, I was able to test them properly and the test results was the proof in the pudding !!

I measured a THD of .5% at the edge of the cores saturation point at 300hz, and it dropped to .1% as the frequency was raised past the core saturation at 360-400hz or so.

By the time I got to 1000hz now I was seeing less than about .05% until I could not even register anything below .01% -.005% as that was the THD limit of my sound card (Gina24).

I play guitar and I love my music Loud at times but now after my recording days my music must be very clean more so than just loud !!

So, when I blew up my last set of tweeter's and midrange's I had enough of replacing them all the time............................

And, I took out those little 7 year old panels and said to myself... "Self these little panels are the same size, they have the same amount of surface area and more displacement as those expensive drivers dynamic drivers that I keep frying!!! ....These Have To Work !!! " ...... And that is how it all started !!

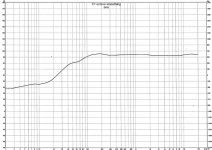

So I set out to do so and figured out what it takes for their sensitivity to match that of a woofer.

Since they didn't have the benefit of the surface area that a larger panel has (as I built two size at the time, the bigger ones had 4 times the surface area at 7.5"x 19") I knew that I had too somehow increase the drive on them.

The bigger one could play well down past 100-200hz for fullrange, but the reason I made them was to see if there really is an increase of +3 or +6db ( I forget which) sensitivity under the same driving conditions.

But, I never had a chance to check that out.

It had about the same displacement as an 8"-10" woofer or so.

Well ya, I could increase the transformation ratio and use a huge amp with a large voltage swing, but at the time all of those amps were still down in Fla. and doing so opens whole another can of worms to contend with.

All I had was an 80watt cheapy Awia CD combo unit and besides I wanted the design to work off of such an amp anyhow.

And then I realized that raising the bias had to be the secret... And it was !!

For that little panel to match that of the woofer of 87-89db at 1 watt I had to run them at 7Kv of bias using my 1:160 step up ratio.

The setup you see with the 8" sub was the result of match sensitivity using both channels of that little Awia Workhorse.

That was when I did the R&D thread on ESL Transformer design and designed my Regulated Variable 0-14kv bias supply.

When I first made the things in 2003 I ran similar voltages on them already, only I was using some old Motorola 6V6 OPT's that I had.

But they eventually broke down and I destroyed them, However they worked long enough for me enjoy them for a while and I figured out what I needed to do.

Then Life's stupid mistakes got in the way for a while. :/

Fast forward to 2010 I got them out built all new electronics as when I built them you couldn't get a toroidal transformer here in the states back then let alone cheap enough.

I had just got 10x 200watt transformers for a deal at Parts Express in 2008 and got back on DIYa to see what was going on in the world of ESL's and found that Calvin and CharlieM's builds were using such transformers to drive them

In February I made friends with Charlie and Nate ( AKA Maveric) and gave them some insight as they were building Maverics ESL's (the very same ones that I now have) shown in post #7 of this thread and elsewhere.

And in March of 2010 I decided to give them a try ..... My new cores Worked !!!! :O

And my Panels came alive for the first time in 7 years with out doing anything to them at all.

They fired right up and played just like they did when I built them without even giving a them good clean, they were loaded with Dirt, Sand and Road Salt as described in another thread, yet the Licron coating held up after that !!

In fact, When I made my very last tests and burned it up I didn't even realize that, that one particular diaphragm was the original one that had the older Licron coating on it !!!

The other one I had replaced the Mylar and it was coated with the newer Crystal version from Chemspray.

Accuracy you ask read this,

High strength Dielectric Coatings, fact or fiction

As a testament to how well the little black mesh ones sounded before I had a woofer system matched up to them,

"Before I built my first panels I had listened to some ML's and my very first panels were not any different as far as midrange and high frequency's are concerned and the sound quality is second to none IMHO.

They sounded so accurate that one time when I was listening to a cassette recording of some rain and forest sounds, my dog would go to the door to watch the rain.

But she would not go outside for fear of getting wet, But There Was NO RAIN (ha,ha,ha).

She is now dubbed the Infamous Sadie in these threads."

Seriously it was not raining but she thought it was !!!

You see she is a Florida dog and it rained every day there and she used to love to sit and look out the screen door and watch it pour!!! "

And the Rest is all history from there on out !!

jer

I wanted to build a set of magi's but I have a lot of tape equipment, so I didn't want any strong magnetic fields in their vicinity..... At All !!

That is the main reason I chose to go with ESL's, Besides the fact that I have been obsessed with ESL's since I was in Grade School after reading about the 57's in an issue of Popular mechanics in the mid 70's.

However I do have a very aging set of Apogee Duette's, and the first time I had heard them ...... I was blown away !!!

Then I discovered Roger Sanders and David P. Hermeyer's build's in 84 the 1980 Audio Amateur Handbook, and that was what got me going.

As far as the sound, the Apogee's were Top Notch and I could not believe what I was hearing.

Then as I was starting building mine I manged to find a set of Martin Logan ESL's in a local shop just to listen too and just to find out what I was up against and what to expect.....Again was blown away !!!

But when I got my panels done I found that the sound was a bit more detailed than what I was used to listening to with my Apogee's in the 90's and that was without having a woofer to fill in the bottom end.

My Friend Dave, whom I ran my recording studio with, liked them a lot, but he is impartial to the Duette's only because my setup didn't have a woofer for the low end, this is understandable as well but he did notice the amount of detail that they could pullout.

In Fact IMHO it seemed that there was too much detail (He,he,he) and I found it difficult to listen to such classics such as PinkFlyod's "Dark Side of the Moon" or Peter Frampton's " Comes Alive" albums and with no low end to fill everything in you could hear every single edit and splice that was made during the creation process of the recording and that was off of old Vinyl Records !!!

Also stereo imaging was much better than what I heard from the ML's, I am saying this with a very unbiased observation.

Just because I made them doesn't mean that they sounded better, But, They really did sound much clearer to me ignoring the fact that they had no low end because I had not added a woofer yet.

7 years later when I got them back out and running again, finally, I was able to test them properly and the test results was the proof in the pudding !!

I measured a THD of .5% at the edge of the cores saturation point at 300hz, and it dropped to .1% as the frequency was raised past the core saturation at 360-400hz or so.

By the time I got to 1000hz now I was seeing less than about .05% until I could not even register anything below .01% -.005% as that was the THD limit of my sound card (Gina24).

I play guitar and I love my music Loud at times but now after my recording days my music must be very clean more so than just loud !!

So, when I blew up my last set of tweeter's and midrange's I had enough of replacing them all the time............................

And, I took out those little 7 year old panels and said to myself... "Self these little panels are the same size, they have the same amount of surface area and more displacement as those expensive drivers dynamic drivers that I keep frying!!! ....These Have To Work !!! " ...... And that is how it all started !!

So I set out to do so and figured out what it takes for their sensitivity to match that of a woofer.

Since they didn't have the benefit of the surface area that a larger panel has (as I built two size at the time, the bigger ones had 4 times the surface area at 7.5"x 19") I knew that I had too somehow increase the drive on them.

The bigger one could play well down past 100-200hz for fullrange, but the reason I made them was to see if there really is an increase of +3 or +6db ( I forget which) sensitivity under the same driving conditions.

But, I never had a chance to check that out.

It had about the same displacement as an 8"-10" woofer or so.

Well ya, I could increase the transformation ratio and use a huge amp with a large voltage swing, but at the time all of those amps were still down in Fla. and doing so opens whole another can of worms to contend with.

All I had was an 80watt cheapy Awia CD combo unit and besides I wanted the design to work off of such an amp anyhow.

And then I realized that raising the bias had to be the secret... And it was !!

For that little panel to match that of the woofer of 87-89db at 1 watt I had to run them at 7Kv of bias using my 1:160 step up ratio.

The setup you see with the 8" sub was the result of match sensitivity using both channels of that little Awia Workhorse.

That was when I did the R&D thread on ESL Transformer design and designed my Regulated Variable 0-14kv bias supply.

When I first made the things in 2003 I ran similar voltages on them already, only I was using some old Motorola 6V6 OPT's that I had.

But they eventually broke down and I destroyed them, However they worked long enough for me enjoy them for a while and I figured out what I needed to do.

Then Life's stupid mistakes got in the way for a while. :/

Fast forward to 2010 I got them out built all new electronics as when I built them you couldn't get a toroidal transformer here in the states back then let alone cheap enough.

I had just got 10x 200watt transformers for a deal at Parts Express in 2008 and got back on DIYa to see what was going on in the world of ESL's and found that Calvin and CharlieM's builds were using such transformers to drive them

In February I made friends with Charlie and Nate ( AKA Maveric) and gave them some insight as they were building Maverics ESL's (the very same ones that I now have) shown in post #7 of this thread and elsewhere.

And in March of 2010 I decided to give them a try ..... My new cores Worked !!!! :O

And my Panels came alive for the first time in 7 years with out doing anything to them at all.

They fired right up and played just like they did when I built them without even giving a them good clean, they were loaded with Dirt, Sand and Road Salt as described in another thread, yet the Licron coating held up after that !!

In fact, When I made my very last tests and burned it up I didn't even realize that, that one particular diaphragm was the original one that had the older Licron coating on it !!!

The other one I had replaced the Mylar and it was coated with the newer Crystal version from Chemspray.

Accuracy you ask read this,

High strength Dielectric Coatings, fact or fiction

As a testament to how well the little black mesh ones sounded before I had a woofer system matched up to them,

"Before I built my first panels I had listened to some ML's and my very first panels were not any different as far as midrange and high frequency's are concerned and the sound quality is second to none IMHO.

They sounded so accurate that one time when I was listening to a cassette recording of some rain and forest sounds, my dog would go to the door to watch the rain.

But she would not go outside for fear of getting wet, But There Was NO RAIN (ha,ha,ha).

She is now dubbed the Infamous Sadie in these threads."

Seriously it was not raining but she thought it was !!!

You see she is a Florida dog and it rained every day there and she used to love to sit and look out the screen door and watch it pour!!! "

And the Rest is all history from there on out !!

jer

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Help a new member with electrostats!