Hi whsh93a, interesting, can you share a bit more - picture or dimensions of the panel, and what kind of video tape. I read they are 3 thicknesses, starting from 0.5 mil, and it seems a bit high. What is the uncorrected frequency response you managed to achieve?

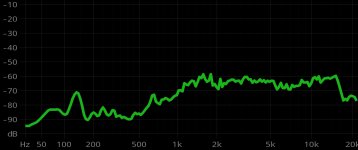

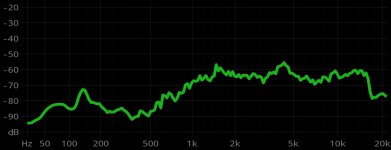

I've been snowboarding. I used Beta L-750 tape. The longer the cassette time the thinner the tape ( L-830, a delicate, tissue paper-like tape only 13- microns). I've posted an image taken from my usual listening place about ten feet away and from about 5 feet away using FM interstation noise for an idea of the frequency response (good for about 15KHz) but not including the sub. Crossiver is 800 Hz because it sounds best there. The hump at 120Hz is my fridge. I used a slightly modified CFL ballast for the HV bias. The individual panels are gimbled to allow me to adjust directionality. Four panels per speaker about 20" x 2". Each panel has four divisions- three shorter 3" long for highs and one 9.5" for mids. For transformers I use one standard ESL type for one speaker and in series four standard 70V audio distribution transformers in the other speaker. The four 70V transformers are superior sounding. I'll probably switch the other speaker to them eventually. Time passes - not sure if the photos are being uploaded.

Attachments

Last edited:

Hi - not knowing why you would like to find film that need not be covered but in case you are interested this seller has 1um & 0.5um mylar (OS) films:

Free Flight Supplies - Lightweight Covering Materials For Sale

Cheers,

Jesper

Free Flight Supplies - Lightweight Covering Materials For Sale

Cheers,

Jesper

Hi - not knowing why you would like to find film that need not be covered but in case you are interested this seller has 1um & 0.5um mylar (OS) films:

Free Flight Supplies - Lightweight Covering Materials For Sale

Cheers,

Jesper

Be ready for some seriously delicate work if you play with mylar that thin. Your work surfaces have to be meticulously clean and free of burrs etc. I've got 1.2um film that I've used for dust covers and it's tricky to work with. Making the dust cover itself is easy, but the handling it for installation and heat shrinking it to remove wrinkles takes some real finesse.

I've never tried films thinner than 3um for diaphragms though, I don't think you could maintain enough tension to prevent cell collapse in the ESLs I have built. The 50:1 to 100:1 ratio rule of thumb would have to be reduced a bit I'd imagine.

Sheldon

If anyone is looking for 6um Aluminized mylar (I know, not the same - Constant Voltage / Constant Charge), you can find it at Message Parlor Distribution outlets (I had some explaining to do to the wife when it arrived years ago). I got a 30" wide roll for like $30 that will cover a football field.

I replaced the mylar on a Martin Logan CLS stators years ago and it sounded pretty darn good with a DIY interface with the pair of Antec AS-1206 toroids...I scrapped it eventually after realizing the fire hazard that exists with these Constant Voltage type ESLs, even with the 20meg ohm resistor on the bias feed.

Someday I will try it again...

I replaced the mylar on a Martin Logan CLS stators years ago and it sounded pretty darn good with a DIY interface with the pair of Antec AS-1206 toroids...I scrapped it eventually after realizing the fire hazard that exists with these Constant Voltage type ESLs, even with the 20meg ohm resistor on the bias feed.

Someday I will try it again...

Hi - not knowing why you would like to find film that need not be covered but in case you are interested this seller has 1um & 0.5um mylar (OS) films:

Free Flight Supplies - Lightweight Covering Materials For Sale

Cheers,

Jesper

The 5 micron aluminised must have very thin layer of aluminium! Maybe a suitable resistance for an ESL?

Vacuum deposited aluminum on mylar is typically 20-30 nm. It can't be very thick because the heat would distort the mylar from the very hot aluminum atoms. You can make a reasonable estimate of the thickness from the light attenuation. I have a reference for that at work, but I can't recall the relationship extactly. I recall that 1% transmission is about 25nm

Sheldon

Sheldon

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- best plastic film for ESL speakers