I am completely new to electrostatic speakers and am thinking of making one just for fun.

I was using these as tutorials:

ESL Driver Construction

http://www.introni.it/pdf/Sanders - Electrostatic Loudspeaker Design Cookbook 1995.pdf

I'm not sure what I have to connect to what so can you guys help me on that?

Also, am I missing any parts (or am I using the wrong part) ?

Thanks for the help

7VA Toroidal Voltage Transformers Audio Transformer Dual 110V 115V120V 50 60Hz | eBay

Emco F40 High Voltage Power Supply Module 4KV 4 000 Volts Brick "A" Grade | eBay

3M 4941 VHB Double-Sided Acrylic Foam Tape, 45 mil, 0.5" x 5 Yards (Dark Grey): Adhesive Tapes: Amazon.com: Industrial & Scientific

Custom Speaker Grills

McMaster-Carr

I was using these as tutorials:

ESL Driver Construction

http://www.introni.it/pdf/Sanders - Electrostatic Loudspeaker Design Cookbook 1995.pdf

I'm not sure what I have to connect to what so can you guys help me on that?

Also, am I missing any parts (or am I using the wrong part) ?

Thanks for the help

7VA Toroidal Voltage Transformers Audio Transformer Dual 110V 115V120V 50 60Hz | eBay

Emco F40 High Voltage Power Supply Module 4KV 4 000 Volts Brick "A" Grade | eBay

3M 4941 VHB Double-Sided Acrylic Foam Tape, 45 mil, 0.5" x 5 Yards (Dark Grey): Adhesive Tapes: Amazon.com: Industrial & Scientific

Custom Speaker Grills

McMaster-Carr

Hi,

welcome to the pleasure dome and the hell of electrostatics

It´s nice to see that You´ve already informed Yourself about the whats and whys, but I suggest to follow this ´theoretical´ path a little further before starting to collect parts and devices.

I mean, that You might be better off if You think about and decide for a certain concept first.

As usual I suggest to build a medium or smaller sized Hybrid-Panel first as the chance of success is alot higher than with a FR panel and the output can for sure be way better in any respect.

The three devices You list might or might not be suitable for what You intend do.

For example is a HV-supply of 1-3W more than sufficient and there are for sure other and cheaper alternatives.

The tapes should be chosen after the application, i.e. the materials and surfaces which shall stick to each other.

There´s mostly a PET film used as diaphragm material, but the the frame or stator insulation may differ grossly.

Which amount of mechanical stress burdens the glue joint?

Which thicknes of tape is required?

Is tape the glue of choice, or would a different glue be advantageous/ceaper/easier to handle?

For starters I also suggest to experiment with flat wire stators first as it bears the greatest chance for a successful build.

It also unburdens You from a few detail issues like how to manufacture a safe and reliable stator insulation, or how to create a safe, good and reliable curved stator design.

Besides, cost flat wire stator designs tyically less than metal sheet stators.

jauu

Calvin

welcome to the pleasure dome and the hell of electrostatics

It´s nice to see that You´ve already informed Yourself about the whats and whys, but I suggest to follow this ´theoretical´ path a little further before starting to collect parts and devices.

I mean, that You might be better off if You think about and decide for a certain concept first.

As usual I suggest to build a medium or smaller sized Hybrid-Panel first as the chance of success is alot higher than with a FR panel and the output can for sure be way better in any respect.

The three devices You list might or might not be suitable for what You intend do.

For example is a HV-supply of 1-3W more than sufficient and there are for sure other and cheaper alternatives.

The tapes should be chosen after the application, i.e. the materials and surfaces which shall stick to each other.

There´s mostly a PET film used as diaphragm material, but the the frame or stator insulation may differ grossly.

Which amount of mechanical stress burdens the glue joint?

Which thicknes of tape is required?

Is tape the glue of choice, or would a different glue be advantageous/ceaper/easier to handle?

For starters I also suggest to experiment with flat wire stators first as it bears the greatest chance for a successful build.

It also unburdens You from a few detail issues like how to manufacture a safe and reliable stator insulation, or how to create a safe, good and reliable curved stator design.

Besides, cost flat wire stator designs tyically less than metal sheet stators.

jauu

Calvin

Try to get this book:

Electrostatic Loudspeaker: Design and Construction: Amazon.co.uk: Ronald Wagner: Books

It has much less tunnelvision then the Sanders book.

For real good theory look for Baxandall en Streng articles.

Quad ESL Theory

Electrostatic Loudspeaker: Design and Construction: Amazon.co.uk: Ronald Wagner: Books

It has much less tunnelvision then the Sanders book.

For real good theory look for Baxandall en Streng articles.

Quad ESL Theory

Here is some more info to help get you started,

Elektrostatic Loudspeakers

As Calvin mentioned, ESL's need not be big to get that Big Sound!!!

A Desktop ESL Build

A Segmented Stator Desktop ESL

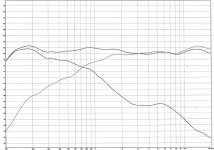

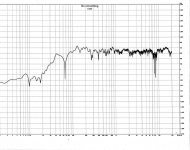

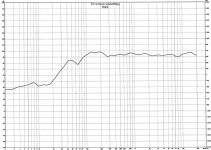

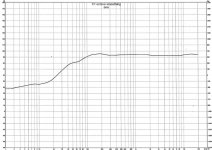

I just found the Precision frequency plots of my little system the other day!!!

I have measured in excess of +105db with this little setup as the little woofer can't keep up much over 100db or so.

The plots are calibrated in db as well.

Enjoy!!!

jer

Elektrostatic Loudspeakers

As Calvin mentioned, ESL's need not be big to get that Big Sound!!!

A Desktop ESL Build

A Segmented Stator Desktop ESL

I just found the Precision frequency plots of my little system the other day!!!

I have measured in excess of +105db with this little setup as the little woofer can't keep up much over 100db or so.

The plots are calibrated in db as well.

Enjoy!!!

jer

Attachments

Last edited:

I was planning on

12x48 inch stators

Mid- high frequency (if it works, then i'll put in some kind of woofer and crossover)

If you look at the how its made video for electrostatic speaker, martin logan uses 3m vhb double sided tape to keep space in between diaphragm and stators. I think that would be easiest, but i'm not sure what spacer they use to go in the middle of the stator.

I can't find anything cheaper for the dc bias supply. Some people say neon light ps are good but that would be too much current and too dangerous for me. I emailed a few high voltage tranformer companies for pricing and that used emco is the cheapest i could find.

I could use the emco g30 or 40 series(i havent gotten a reply about cost) They are 1-3 watts.

12x48 inch stators

Mid- high frequency (if it works, then i'll put in some kind of woofer and crossover)

If you look at the how its made video for electrostatic speaker, martin logan uses 3m vhb double sided tape to keep space in between diaphragm and stators. I think that would be easiest, but i'm not sure what spacer they use to go in the middle of the stator.

I can't find anything cheaper for the dc bias supply. Some people say neon light ps are good but that would be too much current and too dangerous for me. I emailed a few high voltage tranformer companies for pricing and that used emco is the cheapest i could find.

I could use the emco g30 or 40 series(i havent gotten a reply about cost) They are 1-3 watts.

I forgot to add the diaphragm

Electrostatic Speaker Membrane Dupont Mylar C 6um 40M | eBay

Electrostatic Speaker Membrane Dupont Mylar C 6um 40M | eBay

Try to get this book:

Electrostatic Loudspeaker: Design and Construction: Amazon.co.uk: Ronald Wagner: Books

It has much less tunnelvision then the Sanders book.

For real good theory look for Baxandall en Streng articles.

Quad ESL Theory

I might actually buy that book. Does it have noob compatible instructions?

Welcome to the forum and the psychosis,

I have both Wagner's and Sanders' book. Both are a bit dated now, especially Wagner's book, but I think Sanders' book has more practical and timely information.

For a hybrid panel, I would use .062 3M polyurethane foam tape spacers, rather than the .045 tape you referenced. Flat perf metal panels are the easiest to build but you have to coat them well.

After Calvin showed us how inexpensive toroidal power transformers work very well for ESL step-up transformers, many of us here on the forum now use tandem 50VA 230V/2x6V toroids (2 each speaker, 4 total).

Online Metals is the cheapest source I've found for perf metal. They only have 40% open with .125 holes but it works perfectly and makes a very efficient panel. (I think 40% open actually sounds better than higher open area): Order Mild Steel A36 Perforated Sheet in Small Quantities at OnlineMetals.com

You might find this link helpful too: Jazzman's DIY Electrostatic Loudspeaker Page

Good luck with your project!

Charlie

I have both Wagner's and Sanders' book. Both are a bit dated now, especially Wagner's book, but I think Sanders' book has more practical and timely information.

For a hybrid panel, I would use .062 3M polyurethane foam tape spacers, rather than the .045 tape you referenced. Flat perf metal panels are the easiest to build but you have to coat them well.

After Calvin showed us how inexpensive toroidal power transformers work very well for ESL step-up transformers, many of us here on the forum now use tandem 50VA 230V/2x6V toroids (2 each speaker, 4 total).

Online Metals is the cheapest source I've found for perf metal. They only have 40% open with .125 holes but it works perfectly and makes a very efficient panel. (I think 40% open actually sounds better than higher open area): Order Mild Steel A36 Perforated Sheet in Small Quantities at OnlineMetals.com

You might find this link helpful too: Jazzman's DIY Electrostatic Loudspeaker Page

Good luck with your project!

Charlie

Last edited:

Thanks for the links.Welcome to the forum and the psychosis,

I have both Wagner's and Sanders' book. Both are a bit dated now, especially Wagner's book, but I think Sanders' book has more practical and timely information.

For a hybrid panel, I would use .062 3M polyurethane foam tape spacers, rather than the .045 tape you referenced. Flat perf metal panels are the easiest to build but you have to coat them well.

After Calvin showed us how inexpensive toroidal power transformers work very well for ESL step-up transformers, many of us here on the forum now use tandem 50VA 230V/2x6V toroids (2 each speaker, 4 total).

Online Metals is the cheapest source I've found for perf metal. They only have 40% open with .125 holes but it works perfectly and makes a very efficient panel. (I think 40% open actually sounds better than higher open area): Order Mild Steel A36 Perforated Sheet in Small Quantities at OnlineMetals.com

You might find this link helpful too: Jazzman's DIY Electrostatic Loudspeaker Page

Good luck with your project!

Charlie

Im just confused about the torodial transformers. What do they need to be connected to? That jazzman link shows the signal from amp connecting to transformer and then to each stator. Then the dc bias supply connects with the membrane. How do you use 2 torodial transformers per speaker?

Last edited:

The schematic shows the complete circuit that powers the ESL panel. The transformers and ESL panels are both powered by the amplifier. The small DC bias supply, which charges the diaphragm, is powered separately from a wall outlet supplying 115 volt house current.

A typical audio amplifier has plenty of current but not nearly enough voltage to power an ESL panel. This is why we must have transformers in the circuit between the amplifier and panel-- to step up the voltage from the tens of volts coming out of the amplifier to the several thousand volts needed to drive the panel.

As the schematic shows:

- The amp leads (speaker cables) connect to the input windings of the transformer pair.

- The ESL panel's two stators connect to the output windings of the transformer pair.

- The DC bias supply's ground lead connects between the output windings of the two transformers. This floating ground keeps the charge on the diaphragm properly biased relative to the alternating charges on the stators.

This is the complete circuit.

What isn't shown is the woofer circuit. In my system, the woofers and ESL panels are controlled and powered separately using an active crossover and separate amplifiers for the woofer and ESL.

I'm not smart enough to design a passive crossover for a hybrid ESL, as would be required to power the panel and woofers from a single amplifier. Not that I would want to anyway, because an active crossover and separate amplifiers is far superior to a single amp with passive crossovers.

A typical audio amplifier has plenty of current but not nearly enough voltage to power an ESL panel. This is why we must have transformers in the circuit between the amplifier and panel-- to step up the voltage from the tens of volts coming out of the amplifier to the several thousand volts needed to drive the panel.

As the schematic shows:

- The amp leads (speaker cables) connect to the input windings of the transformer pair.

- The ESL panel's two stators connect to the output windings of the transformer pair.

- The DC bias supply's ground lead connects between the output windings of the two transformers. This floating ground keeps the charge on the diaphragm properly biased relative to the alternating charges on the stators.

This is the complete circuit.

What isn't shown is the woofer circuit. In my system, the woofers and ESL panels are controlled and powered separately using an active crossover and separate amplifiers for the woofer and ESL.

I'm not smart enough to design a passive crossover for a hybrid ESL, as would be required to power the panel and woofers from a single amplifier. Not that I would want to anyway, because an active crossover and separate amplifiers is far superior to a single amp with passive crossovers.

Last edited:

Hi,

there are numerous 3M VHB types, differing not only by width, colour and thickness, but also by the material.

A successful glue joint requires to find the right tape, depending on the surface energy of the materials and surfaces to glue, the amount of mechanical stress and the thickness of the tape.

There are specialized tapes for high medium and low surface energy materials.

So be sure to choose the right one for Your application.

As You may imagine is shear the most prominent stress on the glue joint and it becomes a increasing problem with increasing thickness of the tape.

I'd regard 1.5mm as the upper thickness limit.

As the amount of force the glue joint may take depends on the area, You need to maximize this area.

At the same -and in contrary- You want to keep this area as small as possible -at least with metal sheet stators- as it represents additional capacitance that cannot be used for acoustic output.

Efficiency but is the most important key factor to a good ESL design.

The clear horizontal spacers were originally made from the highly transparent VHB tapes of 3M.

The newer clear spars rather look like a sandwich made from a transparent hard plastic film (PC or similar) and very thin coreless VHB film.

Besides beeing cheaper a only single side taped plastic film would allow ML to fix the two stators together only at the top and bottom rim, as they had done in their legacy panels.

The panels will then resonate and rattle, but hey, who cares if it saves one $ in production and defect panels are easy servicable, at least in theory.

The curvature and cistomer's bad hearing will hopefully save the day

As for the HV bias supply You may build a classic transformer/cascade, or search for cold lamp light supplies (royer converter) which You can often find in surplus or at ebay.

One of the most critical procedures in manufacture regards the insulation of the stators.

You should really think well about sparing You the hassle of coating metal sheets and choosing wire stators instead.

If Your experience in painting thick and very even layers of paint is low, I'd strongly suggest to take the wire way.

Besides it'd spare You the hassle of bending metal sheets, as for a full metal stator the curvature is rather a must than an option.

Wire stators allow for easy segmentation, which in turn allows the use of cheaper lower quality transformers (even multiple EI-cores).

The requirements against the driving amplifier are also much less stringent.

A metal sheet panel driven over a toroid may reduce the number of suitable amplifiers to <10% of those suitable to drive a segmented wire panel/low quality transformer.

So, choose carefully on the option You have.

The path to Endor is full of nasty traps and deadly obstacles.

jauu

Calvin

there are numerous 3M VHB types, differing not only by width, colour and thickness, but also by the material.

A successful glue joint requires to find the right tape, depending on the surface energy of the materials and surfaces to glue, the amount of mechanical stress and the thickness of the tape.

There are specialized tapes for high medium and low surface energy materials.

So be sure to choose the right one for Your application.

As You may imagine is shear the most prominent stress on the glue joint and it becomes a increasing problem with increasing thickness of the tape.

I'd regard 1.5mm as the upper thickness limit.

As the amount of force the glue joint may take depends on the area, You need to maximize this area.

At the same -and in contrary- You want to keep this area as small as possible -at least with metal sheet stators- as it represents additional capacitance that cannot be used for acoustic output.

Efficiency but is the most important key factor to a good ESL design.

The clear horizontal spacers were originally made from the highly transparent VHB tapes of 3M.

The newer clear spars rather look like a sandwich made from a transparent hard plastic film (PC or similar) and very thin coreless VHB film.

Besides beeing cheaper a only single side taped plastic film would allow ML to fix the two stators together only at the top and bottom rim, as they had done in their legacy panels.

The panels will then resonate and rattle, but hey, who cares if it saves one $ in production and defect panels are easy servicable, at least in theory.

The curvature and cistomer's bad hearing will hopefully save the day

As for the HV bias supply You may build a classic transformer/cascade, or search for cold lamp light supplies (royer converter) which You can often find in surplus or at ebay.

One of the most critical procedures in manufacture regards the insulation of the stators.

You should really think well about sparing You the hassle of coating metal sheets and choosing wire stators instead.

If Your experience in painting thick and very even layers of paint is low, I'd strongly suggest to take the wire way.

Besides it'd spare You the hassle of bending metal sheets, as for a full metal stator the curvature is rather a must than an option.

Wire stators allow for easy segmentation, which in turn allows the use of cheaper lower quality transformers (even multiple EI-cores).

The requirements against the driving amplifier are also much less stringent.

A metal sheet panel driven over a toroid may reduce the number of suitable amplifiers to <10% of those suitable to drive a segmented wire panel/low quality transformer.

So, choose carefully on the option You have.

The path to Endor is full of nasty traps and deadly obstacles.

jauu

Calvin

I probably won't be able to build anything like that. This will probably be my first time even soldering anything...Hi,

there are numerous 3M VHB types, differing not only by width, colour and thickness, but also by the material.

A successful glue joint requires to find the right tape, depending on the surface energy of the materials and surfaces to glue, the amount of mechanical stress and the thickness of the tape.

There are specialized tapes for high medium and low surface energy materials.

So be sure to choose the right one for Your application.

As You may imagine is shear the most prominent stress on the glue joint and it becomes a increasing problem with increasing thickness of the tape.

I'd regard 1.5mm as the upper thickness limit.

As the amount of force the glue joint may take depends on the area, You need to maximize this area.

At the same -and in contrary- You want to keep this area as small as possible -at least with metal sheet stators- as it represents additional capacitance that cannot be used for acoustic output.

Efficiency but is the most important key factor to a good ESL design.

The clear horizontal spacers were originally made from the highly transparent VHB tapes of 3M.

The newer clear spars rather look like a sandwich made from a transparent hard plastic film (PC or similar) and very thin coreless VHB film.

Besides beeing cheaper a only single side taped plastic film would allow ML to fix the two stators together only at the top and bottom rim, as they had done in their legacy panels.

The panels will then resonate and rattle, but hey, who cares if it saves one $ in production and defect panels are easy servicable, at least in theory.

The curvature and cistomer's bad hearing will hopefully save the day

As for the HV bias supply You may build a classic transformer/cascade, or search for cold lamp light supplies (royer converter) which You can often find in surplus or at ebay.

One of the most critical procedures in manufacture regards the insulation of the stators.

You should really think well about sparing You the hassle of coating metal sheets and choosing wire stators instead.

If Your experience in painting thick and very even layers of paint is low, I'd strongly suggest to take the wire way.

Besides it'd spare You the hassle of bending metal sheets, as for a full metal stator the curvature is rather a must than an option.

Wire stators allow for easy segmentation, which in turn allows the use of cheaper lower quality transformers (even multiple EI-cores).

The requirements against the driving amplifier are also much less stringent.

A metal sheet panel driven over a toroid may reduce the number of suitable amplifiers to <10% of those suitable to drive a segmented wire panel/low quality transformer.

So, choose carefully on the option You have.

The path to Endor is full of nasty traps and deadly obstacles.

jauu

Calvin

Toroids look great ( frequency response) but have many problems.

They have a huge problem if there is any dc from your amplifier on it. They can a have saturation problem because the have no air gap, also linearity is a problem ( depends on the frequency you will use them, >300Hz or higher please) For a good hybride esl you want a esl- unit starting at 80-100Hz.

Standard toroids are not designed for high voltage audio but they are cheap, for real quality you need something else.

It was long time ago that i read the Sanders book but i was heavely disapointed because the lack of good information about segmentated esl's

They have a huge problem if there is any dc from your amplifier on it. They can a have saturation problem because the have no air gap, also linearity is a problem ( depends on the frequency you will use them, >300Hz or higher please) For a good hybride esl you want a esl- unit starting at 80-100Hz.

Standard toroids are not designed for high voltage audio but they are cheap, for real quality you need something else.

It was long time ago that i read the Sanders book but i was heavely disapointed because the lack of good information about segmentated esl's

Welcome to the forum and the psychosis,

I have both Wagner's and Sanders' book. Both are a bit dated now, especially Wagner's book, but I think Sanders' book has more practical and timely information.

For a hybrid panel, I would use .062 3M polyurethane foam tape spacers, rather than the .045 tape you referenced. Flat perf metal panels are the easiest to build but you have to coat them well.

After Calvin showed us how inexpensive toroidal power transformers work very well for ESL step-up transformers, many of us here on the forum now use tandem 50VA 230V/2x6V toroids (2 each speaker, 4 total).

Online Metals is the cheapest source I've found for perf metal. They only have 40% open with .125 holes but it works perfectly and makes a very efficient panel. (I think 40% open actually sounds better than higher open area): Order Mild Steel A36 Perforated Sheet in Small Quantities at OnlineMetals.com

You might find this link helpful too: Jazzman's DIY Electrostatic Loudspeaker Page

Good luck with your project!

Charlie

Last edited:

Toroids look great ( frequency response) but have many problems.

They have a huge problem if there is any dc from your amplifier on it. They can a have saturation problem because the have no air gap, also linearity is a problem ( depends on the frequency you will use them, >300Hz or higher please) For a good hybride esl you want a esl- unit starting at 80-100Hz.

Standard toroids are not designed for high voltage audio but they are cheap, for real quality you need something else.

It was long time ago that i read the Sanders book but i was heavely disapointed because the lack of good information about segmentated esl's

I'm sure there are better transformer options for ESL's. Especially for those with experience to design and wind their own. I'm just attesting that the tandem 50VA 230v/6v toroids powering my hybrids since 2009 are cheap, they sound wonderful, and my Carver TFM amps drive them with aplomb.

Regarding Sanders' Cookbook, it's dated and definitely lacking in some respects. I haven't seen any ESL books that cover segmented wire stator ESL's. Have you considered writing one yourself? I've read some of your posts and you seem quite knowledgeable.

Can I use normal latex paint?Welcome to the forum and the psychosis,

I have both Wagner's and Sanders' book. Both are a bit dated now, especially Wagner's book, but I think Sanders' book has more practical and timely information.

For a hybrid panel, I would use .062 3M polyurethane foam tape spacers, rather than the .045 tape you referenced. Flat perf metal panels are the easiest to build but you have to coat them well.

After Calvin showed us how inexpensive toroidal power transformers work very well for ESL step-up transformers, many of us here on the forum now use tandem 50VA 230V/2x6V toroids (2 each speaker, 4 total).

Online Metals is the cheapest source I've found for perf metal. They only have 40% open with .125 holes but it works perfectly and makes a very efficient panel. (I think 40% open actually sounds better than higher open area): Order Mild Steel A36 Perforated Sheet in Small Quantities at OnlineMetals.com

You might find this link helpful too: Jazzman's DIY Electrostatic Loudspeaker Page

Good luck with your project!

Charlie

No!!!!

Absolutely Not !!!!

Urethane's or Acrylic Enamels should be used.

Nothing that is water based should be used.

Read through this thread to give you an idea,

http://www.diyaudio.com/forums/plan...ectric-coatings-fact-fiction.html#post2779101

jer

Absolutely Not !!!!

Urethane's or Acrylic Enamels should be used.

Nothing that is water based should be used.

Read through this thread to give you an idea,

http://www.diyaudio.com/forums/plan...ectric-coatings-fact-fiction.html#post2779101

jer

I second Jer's advice about water based paints. Be careful when looking at Urethane as well. Some of the Varathane products are water based.

Also, don't be afraid to experiment. Therein lies much of the fun (and the occasional epic fail!).

I have personally had far better results with the segmented wire stator approach.

Also, don't be afraid to experiment. Therein lies much of the fun (and the occasional epic fail!).

I have personally had far better results with the segmented wire stator approach.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- lectrostaComplete newbie.. Cheapish electrostatic speaker build