I have seen that Quad used an oven for applying the Elvamide coating on the original ESL. Anyone any idea how they used the oven in the original ESL process?

I think the oven was used as part of the tensioning process, though it may have been to dry/cure the coating.

Hi David

What are you referring to ?

could you provide a link ?

ER Audio sell a conductive coating, though I have not used it, maybe Sheldon has and might comment.

Step Up Transformer

Hope this link works.

I think the oven was used as part of the tensioning process, though it may have been to dry/cure the coating.

I'd heard the tensioning hypotheses a lot, and I'm not convinced. Sure, it will heat shrink the mylar a bit (some mylar types shrink more than others), but I don't think that was the primary reason. Quad LOVED (and I mean loved) thermoset glues, they are all over all the quad speaker designs.

My guess is that the oven is used to melt the glue to bond the diaphram to the stator. But that's just a guess.

Sheldon

quadesl.com

ER Audio sell a conductive coating, though I have not used it, maybe Sheldon has and might comment.

Step Up Transformer

Hope this link works.

Rob at ER has had a couple coatings over the years, and they have all been good. I'm 99% sure that he is only selling the water based one now (so as not to poison his customers and allow easy shipping). If I understand his coating, it's pretty similar to mine, which uses modern conductive materials which are also used in anti-static coating products. There's a whole world of anti-static powders that get mixed into resins to form conductive coatings. The resistivity is varied (typically logarithmically) by varying the concentration of the powder in the resin.

I use a water based polyester resin which bonds really well to mylar. I also use a dispersant and a little bit of wetting agent. There's a bit of chemistry involved to make sure the pH is right and the particulates don't clump etc, but it's really pretty simple (chemistry isn't my bag). It wipes on and self levels and then dries. In my testing it seems to not change conductivity with humidity level. And so far it lasts 20 years (that's the oldest rebuilt panel I've got using it).

Using a shockingly cheap and crappy surface resistance meter from eBay, I measure 10^7 ohms/sq on the original ESL63 diaphragms, and I've tuned my coating to give me the same resistivity when measured with the same meter. I don't trust the absolute values from that meter, so I do relative measures between diaphragms.

I don't sell my coating, and I point people to ER audio for Rob's coating. It will work well for you. Actually I do sell my coating, but you only get a little of it, dried onto rebuilt quad panels.

Hope that helps,

Sheldon

quadesl.com

Using a shockingly cheap and crappy surface resistance meter from eBay, I measure 10^7 ohms/sq on the original ESL63 diaphragms, and I've tuned my coating to give me the same resistivity when measured with the same meter. I don't trust the absolute values from that meter, so I do relative measures between diaphragms.

Hope that helps,

Sheldon

quadesl.com

Strangely I ordered one of these last week.

GM3110 Capacitance Ohm Meter Capacitor Circuit Tester Resistance Measuring | eBay

YouTube

As I have a neighbour who is a retired Prof of pyhsics I thought I could have it's accuracy checked against proper test equipment, and also thought that so long as it has repeatable measures it will suffice.

I have bought a pair of 'broken' 63's to play with and a set of panels from someone who had a full Quad rebuild.

I run 989's which I bought after a Quad rebuild only to find that they only replaced the panels which had failed.

So a few months later I had to embark on the 'how to rebuild broken Quad ESL's' merry go round.

So I have the following panels on which to test.

Early 63's which had the 2 part sprayed coating

Later 63's with a one part sprayed coating

Original 989 panels

3 year old 'new' Quad panels

Test results to follow, though as the meter is on a slow boat from China it could be Jan/Feb.

Last edited:

So a few months later I had to embark on the 'how to rebuild broken Quad ESL's' merry go round.

So I have the following panels on which to test.

Early 63's which had the 2 part sprayed coating

Later 63's with a one part sprayed coating

Original 989 panels

3 year old 'new' Quad panels

Test results to follow, though as the meter is on a slow boat from China it could be Jan/Feb.

I bought a set of 2912's for a song because 5 of the 12 panels had gone bad. These are 4 year old speakers...

Therein lies a whole new question, completely off topic.

The 2912's weigh twice that of the 989's and have all 'mil spec' components.

So do they sound better ?

Many quote that the 57's are better than 63's which are better than Chinese production 9 and 12 series.

I must listen to some 12 series.

Shame that Grantham is in New Hampshire and not Lincolnshire UK. though I believe you have heard this before

I listen to my 989's naked with supertweeters and DSP subwoofers monoblocked with chip amps.

0.00012 % THD

Parallel-86: High-power composite amplifier achieving 0.00012 % THD.

The 2912's weigh twice that of the 989's and have all 'mil spec' components.

So do they sound better ?

Many quote that the 57's are better than 63's which are better than Chinese production 9 and 12 series.

I must listen to some 12 series.

Shame that Grantham is in New Hampshire and not Lincolnshire UK. though I believe you have heard this before

I listen to my 989's naked with supertweeters and DSP subwoofers monoblocked with chip amps.

0.00012 % THD

Parallel-86: High-power composite amplifier achieving 0.00012 % THD.

Therein lies a whole new question, completely off topic.

The 2912's weigh twice that of the 989's and have all 'mil spec' components.

So do they sound better ?

Many quote that the 57's are better than 63's which are better than Chinese production 9 and 12 series.

I must listen to some 12 series.

Shame that Grantham is in New Hampshire and not Lincolnshire UK. though I believe you have heard this before

I listen to my 989's naked with supertweeters and DSP subwoofers monoblocked with chip amps.

0.00012 % THD

Parallel-86: High-power composite amplifier achieving 0.00012 % THD.

This is totally off-topic, and I'm sorry to all the thread readers.

The 2905 and 2912's have a lot of steel in them. And crazy aluminum side panels. But the electronics are virtually identical to all the other modern quads, going back to the 63's. I'm wondering where these mil-spec parts are. The crossovers in my 2912's are the same crappy parts that have always been part of the quads. Sand-cast wirewound resistors for the 3.3ohm ones. A crappy polyester 1.5uF cap across the transformer primary. The bipolar electrolytic in the signal path is now rated for 105C, but is no better sonically (bypass that sucker with a healthy sized film cap or replace it entirely for better sound). The electronics under the hood are still as underwhelming as always.

Here's what the newest ones look like. The electroncis should look very similar to what you have:

http://quadesl.com/diyaudio/IMG_2870.jpeg

http://quadesl.com/diyaudio/IMG_2871.jpeg

In my humble opinion, the 63's are the best looking of the modern quads. I also find any differences between each of the modern models to be effectively non-existent from a panels and electronics standpoint. The changes are purely cosmetic and structural. The 57's are different, and much more limited in many ways. They can be extremely satisfying with the right source material and electronics, but overall day to day, the modern quads are a better speaker. The 57's when sitting in the sweet spot can be breathtaking. But for a speaker that I have to live with in and out of the sweet spot with all sorts of music, I'll stick with the modern quads.

Sheldon

quadesl.com

Last edited:

I think the oven was used as part of the tensioning process, though it may have been to dry/cure the coating.

Yep was scratching related

I did one quad panel 1 month ago with the ER standing in the exact same spot and i take a measurement the next few months every month.ER Audio sell a conductive coating, though I have not used it, maybe Sheldon has and might comment.

Step Up Transformer

Hope this link works.

According to interview with Ross Walker, the oven is not for tensioning per-se, but for heating while held at constant tension to stabilize the material and avoid creep and reduced tension over time. Quote and reference posted here: https://www.diyaudio.com/forums/pla...ar-thickness-look-3-micron-3.html#post4126172I'd heard the tensioning hypotheses a lot, and I'm not convinced....My guess is that the oven is used to melt the glue to bond the diaphram to the stator. But that's just a guess.

Since you have many ESL-63s passing thru your hands, can you comment about the rubbery coating I found on the diaphragm on the side opposite the conductive coating? The Ross Walker interview talks cryptically of a secret ingredient X damping compound. Was this something you found on most diaphragms?

******

Just noticed link to the interview is no longer active, so attached a copy here.

Attachments

According to interview with Ross Walker, the oven is not for tensioning per-se, but for heating while held at constant tension to stabilize the material and avoid creep and reduced tension over time. Quote and reference posted here: https://www.diyaudio.com/forums/pla...ar-thickness-look-3-micron-3.html#post4126172

Since you have many ESL-63s passing thru your hands, can you comment about the rubbery coating I found on the diaphragm on the side opposite the conductive coating? The Ross Walker interview talks cryptically of a secret ingredient X damping compound. Was this something you found on most diaphragms?

******

Just noticed link to the interview is no longer active, so attached a copy here.

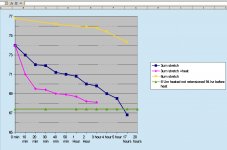

well part of the tension proces , since the mylar relaxes under heat. and it is heat up with a set weight pulling on the fillm. wehn heated it gives a bit but settle at the exact same tension as it would without the heat except it stays at that tension.. Bolserst you might remember, (i cant findd it of course) i made a graph once with 3 um and 6 um foil heated while stretched and non heated. and the drop in resonance you get over time heated vs non heated. ill try to find it somewhere in all; this mess

It is a miracle

here you can see what the heating while stretching does.

the 3um foil i heated stretched back to original resonance heated stretched back to original resonance just as what the weights (or the fingers ) would do while being in the oven.

) would do while being in the oven.

with the 6 micron i stretched it to 94Hz heated it evenly for few minutes. then let it sit. and it remains like that.

You can see both foils that where heated somewhere remained most stable. and the effect is bigger in the thinner foil. 6 um falls of less in general

to bad i took not a bit more points for the 3um heated since i keeps me wondering now if it would be stable where the other one dropped below 67

since i keeps me wondering now if it would be stable where the other one dropped below 67  damned

damned

here you can see what the heating while stretching does.

the 3um foil i heated stretched back to original resonance heated stretched back to original resonance just as what the weights (or the fingers

with the 6 micron i stretched it to 94Hz heated it evenly for few minutes. then let it sit. and it remains like that.

You can see both foils that where heated somewhere remained most stable. and the effect is bigger in the thinner foil. 6 um falls of less in general

to bad i took not a bit more points for the 3um heated

Attachments

Last edited:

I love this comment. Shows a person who knows what he's talking about and uses his eyes and ears and does not try to impress, neither is impressed by marketing BS that is around a lot nowadays.In my humble opinion, the 63's are the best looking of the modern quads. I also find any differences between each of the modern models to be effectively non-existent from a panels and electronics standpoint. The changes are purely cosmetic and structural. The 57's are different, and much more limited in many ways. They can be extremely satisfying with the right source material and electronics, but overall day to day, the modern quads are a better speaker. The 57's when sitting in the sweet spot can be breathtaking. But for a speaker that I have to live with in and out of the sweet spot with all sorts of music, I'll stick with the modern quads.

Sheldon

quadesl.com

I hate this kind of comment.misterdog;5606621 I listen to my 989's naked with supertweeters and DSP subwoofers monoblocked with chip amps. :eek: 0.00012 % THD :) [URL="https://www.neurochrome.com/parallel-86/" said:.[/URL]

Who are you trying to impress besides yourself? Using a subwoofer and supertweeters with ESL's is pure blasfemy in my humble opinion. The linearity and super fast response time that is the charm of an ESL because of the very thin diaphragm are killed and there can never be a coherent sound reproduction. The brilliant concept of the ESL-63 (and later models) being a virtual point source is also killed.

Back on topic. I'm still testing various coatings for ESL-63.

Today's test is seeing the influence of humidity on the coating.

With humidity at 40% the neon light blinks once every 45 seconds

With humidity at 85% the neon light blinks once every 1.5 seconds.

Although the charging is much more rapidly (which is to be expected), I think this is still acceptable.The panels are silent even at these humidities.

Where I live 70% humidity is an exception an 40-55% is pretty standard.

I live at sea level or just above. Any thoughts or comments are appreciated.

Today's test is seeing the influence of humidity on the coating.

With humidity at 40% the neon light blinks once every 45 seconds

With humidity at 85% the neon light blinks once every 1.5 seconds.

Although the charging is much more rapidly (which is to be expected), I think this is still acceptable.The panels are silent even at these humidities.

Where I live 70% humidity is an exception an 40-55% is pretty standard.

I live at sea level or just above. Any thoughts or comments are appreciated.

This is how Quad Musikwiedergabe in Germany uses melt glue on the 63.My guess is that the oven is used to melt the glue to bond the diaphram to the stator. But that's just a guess. Sheldon

quadesl.com

- Home

- Loudspeakers

- Planars & Exotics

- ESL Diaphragm coating