Mr Pass often talks of "fearless amplifier builders". I have to admit, I am not quite so fearless. Maybe it is my naturally cautious nature, I don't know....

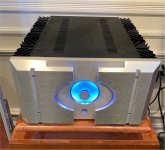

I built a pair of F5 Turbo monoblocks with a couple extra output drivers to handle the crazy loads from my ESLs, and it runs warm. The temp gauge shows 50degC at idle, and up to 60degC when driven. For my own peace of mind, if nothing else, I would prefer to to run a tad cooler.

I have seen a thread before where someone put a fan in the middle of a board and set his amp onto it. Sounded like a good idea, so I did the same. I hated the fan noise. That was much worse than the uneasiness of hot amps. But it did work really well.

So, to reduce fan noise, I took three approaches:

1) find a really quiet fan to begin with. There are some very good ones that have feathered back edges on their blades and good engineering that are very quiet. This helped greatly, but not enough.

2) I made a simple fan controller using a Cypress PSoC running a fuzzy logic algorithm that varied fan speed by temperature. The lower the speed, the lower the fan noise. Basically a simple thermostat with a few different fan speeds based on temperature and whether the temp was rising or falling. This was almost enough. The fan noise was very much reduced. But, like most engineers with a problem on their mind, that was still not quite what I wanted.

3) When fans beat against the air, the blades create an air vibration (noise) based on fan speed, number of blades, etc. This is generally a single frequency plus some harmonics. To counteract this, I added a pseudo-random speed delta to the speed controller. This spread the fan noise out over a range of frequencies. I have not verified this yet, but I believe the total noise to be the same (area under the curve) but the greatest amplitude is very much reduced. Even on the highest speed, I have to be within a couple of feet of the fan to hear it.

With these three in place, from my listening position, I am unable to hear the fan, even when the music is silent. And, the amp now runs at 40-45deg, a level I am much more able to live with.

I built a pair of F5 Turbo monoblocks with a couple extra output drivers to handle the crazy loads from my ESLs, and it runs warm. The temp gauge shows 50degC at idle, and up to 60degC when driven. For my own peace of mind, if nothing else, I would prefer to to run a tad cooler.

I have seen a thread before where someone put a fan in the middle of a board and set his amp onto it. Sounded like a good idea, so I did the same. I hated the fan noise. That was much worse than the uneasiness of hot amps. But it did work really well.

So, to reduce fan noise, I took three approaches:

1) find a really quiet fan to begin with. There are some very good ones that have feathered back edges on their blades and good engineering that are very quiet. This helped greatly, but not enough.

2) I made a simple fan controller using a Cypress PSoC running a fuzzy logic algorithm that varied fan speed by temperature. The lower the speed, the lower the fan noise. Basically a simple thermostat with a few different fan speeds based on temperature and whether the temp was rising or falling. This was almost enough. The fan noise was very much reduced. But, like most engineers with a problem on their mind, that was still not quite what I wanted.

3) When fans beat against the air, the blades create an air vibration (noise) based on fan speed, number of blades, etc. This is generally a single frequency plus some harmonics. To counteract this, I added a pseudo-random speed delta to the speed controller. This spread the fan noise out over a range of frequencies. I have not verified this yet, but I believe the total noise to be the same (area under the curve) but the greatest amplitude is very much reduced. Even on the highest speed, I have to be within a couple of feet of the fan to hear it.

With these three in place, from my listening position, I am unable to hear the fan, even when the music is silent. And, the amp now runs at 40-45deg, a level I am much more able to live with.

Attachments

Babysitter with speed spreader - that sounds to me as Berserker Babysitter

Now that sounds like something that'll get ya 15-20!

3) When fans beat against the air, the blades create an air vibration (noise) based on fan speed, number of blades, etc. This is generally a single frequency plus some harmonics. To counteract this, I added a pseudo-random speed delta to the speed controller. This spread the fan noise out over a range of frequencies. I have not verified this yet, but I believe the total noise to be the same (area under the curve) but the greatest amplitude is very much reduced. Even on the highest speed, I have to be within a couple of feet of the fan to hear it.

If this is your original idea, you should patent it.

I have some NP amps I built, all with fan to help cooling, even if the heatsink is as specified. I do not like things too hot. I find it that two fans from each side blowing gently are far more effective.

I use high quality brushless pc fans and I use half the dc voltage to run them. They are almost silent.

I use high quality brushless pc fans and I use half the dc voltage to run them. They are almost silent.

If this is your original idea, you should patent it.

Thank you AMB4. It is my original idea.

I have been through the patent process a dozen or more times and have been granted seven of them. I have found that unless I have the means to defend the patent in court, it is basically worthless. That is why the idea is published here: to give back to this exceptional community and to express the idea in a public forum preventing others gaining a patent.

That is why the idea is published here: to give back to this exceptional community and to express the idea in a public forum preventing others gaining a patent.

your generosity is exceptional and a model for others.

Mac

Looks to be this one...

Amazon.com: Noctua NF-S12B redux-1200, High Performance Cooling Fan, 3-Pin, 1200 RPM (120mm, Grey): Computers & Accessories

I felt the same way about the heat in the compact F2J monoblocks I built from scratch.

I was going to try an eBay digital thermostat to run the fan. When I tested it I didn’t think I could live with its relay clicking on and off to control the fan.

In the end I used 12v micro cooling fans mounted in the back of my chassis’ run off a dedicated transformer and voltage regulator set to about 7 V.

They are cheap Ratshack fans and one of them is now a little noisy on start up, but quites down after a few minutes so I have to stoop over the amp to hear it. I’ll have to try replacing them when I’m not so lazy.

Amazon.com: Noctua NF-S12B redux-1200, High Performance Cooling Fan, 3-Pin, 1200 RPM (120mm, Grey): Computers & Accessories

I felt the same way about the heat in the compact F2J monoblocks I built from scratch.

I was going to try an eBay digital thermostat to run the fan. When I tested it I didn’t think I could live with its relay clicking on and off to control the fan.

In the end I used 12v micro cooling fans mounted in the back of my chassis’ run off a dedicated transformer and voltage regulator set to about 7 V.

They are cheap Ratshack fans and one of them is now a little noisy on start up, but quites down after a few minutes so I have to stoop over the amp to hear it. I’ll have to try replacing them when I’m not so lazy.

Last edited:

SyBorg, this is super neat. I bought a few laptop coolers on Amazon, but returned all of them. They are way too noisy!

Amazon.com : laptop cooler

Amazon.com : laptop cooler

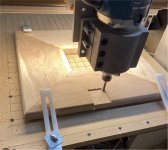

It looks like you prototyped it through Oshpark? (Purple pcb)

If so, any chance you would share the project for other DIYers to buy and use if they want to build some for themselves?

It might make it easier to build if the IC was on a socket...I’d personally be struggling with the other SMD bugs as it is.

If so, any chance you would share the project for other DIYers to buy and use if they want to build some for themselves?

It might make it easier to build if the IC was on a socket...I’d personally be struggling with the other SMD bugs as it is.

In machining it's not a new thing to reduce chatter by randomly varying the spindle speed.

I've played a bit with fans, and my two recommendations for making a fan work as a permanent solution are

a) the fan should blow directly onto the heat sink where it is the hottest

b) filter the air before the fan, or the fan blades will load up with dirt and become unbalanced and noisy, plus it's also blowing dirt into your equipment

I've played a bit with fans, and my two recommendations for making a fan work as a permanent solution are

a) the fan should blow directly onto the heat sink where it is the hottest

b) filter the air before the fan, or the fan blades will load up with dirt and become unbalanced and noisy, plus it's also blowing dirt into your equipment

Noctua fans are the gold standard for quiet cooling. You might have gained a few dB of noise reduction by not firmly mounting the fan to the wood. Vibrations are coupled directly to the wood, basically making it an inefficient but somewhat effective transducer. Using something like the rubber mounts included with the Noctua to absorb the vibrations may help.

I've run into the same problems with fans vibrating in PC cases. The thin metal is pretty good at turning vibrations into sound. Heavy wood shifts the frequency down, but the stiffness doesn't help. Elastic coupling usually helps a great deal.

I've run into the same problems with fans vibrating in PC cases. The thin metal is pretty good at turning vibrations into sound. Heavy wood shifts the frequency down, but the stiffness doesn't help. Elastic coupling usually helps a great deal.

It looks like you prototyped it through Oshpark? (Purple pcb)

...

It might make it easier to build if the IC was on a socket.

Yes, I generally use OSHpark for simple home prototypes. They are relatively fast, high quality, super easy to use and inexpensive.

This family of Cypress PSoC is only available in SMD, and it has been many years since I have used their DIP micro-controllers. I'm sure an older controller would have the hardware resources, there is very little of the capacity of this part being used now. The issue is in porting the software. The interrupt scheme is completely different on the PSoC 1.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Not So Fearless (or, How I Learned to Love the Fan)