Pass DIY Addict

Joined 2000

Paid Member

I am going to experiment with this shortly - I have a few sinks that are natural aluminum and some of the same profile that are painted black vs brown.

I am planning to use an upcoming MoFo build (most simple- single sink, single transistor to mount) to compare various types of mounting interfaces (various silpads, mica&goop, Keratherm, Aluminum oxide ceramic, etc).

This will also give an opportunity to explore paint color vs raw aluminum. Still waiting on a few parts to arrive in the mail, but this should provide some interesting data.

I am planning to use an upcoming MoFo build (most simple- single sink, single transistor to mount) to compare various types of mounting interfaces (various silpads, mica&goop, Keratherm, Aluminum oxide ceramic, etc).

This will also give an opportunity to explore paint color vs raw aluminum. Still waiting on a few parts to arrive in the mail, but this should provide some interesting data.

Is that a philosophical point you are making?Color of the paint on anodized aluminum does NOT matter.

How to anodize without battery acid.

Acid vs non-acid process results look the same in photo.

Anodizing and dyeing aluminum without battery acid... - Observations

Thanks for that link. Very useful!

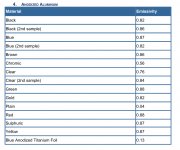

Color of anodizing does matter as the emissivity varies with color. Similar variation in emissivity also occurs with paint colors.

The emissivity of clear anodized is 0.76 to 0.84, close to black (0.82-0.86)

and the plain is just 0.04?

Is that correct?

Who knows. Not cheery picking for sure.Is that a philosophical point you are making?

At least everybody agrees that polishing does not help.Color of anodizing does matter as the emissivity varies with color. Similar variation in emissivity also occurs with paint colors.

With all do respect, most colors in the table of yours have around 0.8. For instance correction pen provides rather accurate reading on FLIR being quite white (probably titanium oxide).

P.S. If it was an scientific paper I would of readily agree.

P.P.S. In respect to paint being the thermal barrier. Usually the specific power flow is small, like 1/3W per inch square so the paint conductivity does not matter that much.

P.P.P.S In industrial environment the proper fan usually suffice so I doubt that appropriate paper exist in non-space related field. Cheers

Last edited:

Ouch!!!I've done some phoning around. I'd have to paint strip the sinks first. Then it would cost about £80 to have them anodized in black.

I might consider it as it apart at the moment with failed PSU caps.

In that case, leave as-is.

In any case, the main cooling effect is still convection, by a large margin, so having a minor variation in the secondary cooling effect is not worth worrying about.

IF you feel cooling is not enough, add a small fan.

Even if undervolted and not moving much air, just a gentle noiseless breeze, you will be *replacing* hot air with fresh one around the heatsinks a few times a minute, and that improves the situation considerably.

Any air flow is better than none.

I often add 12V PC type fans powered by rectified 6.3V filament voltage, so some 8V DC, "somewhere" in tube type Guitar amps.

I am not actually cooling *the tubes* themselves, plates are inside *vacuum* , real Thermos flasks, so they cool by pure Radiation and fan does not affect that, but ambient temperature in and around the chassis drops enough (even if still hot to the touch) to improve overall reliability.

On the contrary, your heatsinks will offer improved cooling.

Last edited:

Pass DIY Addict

Joined 2000

Paid Member

Probably the easiest and most effective thing you can do with your chassis to promote cooling is to make sure there is air circulation through your chassis (which your chimney will certainly accomplish), and to lift the chassis so the bottom of the sinks are 25-30mm (minimum) above the surface the amp sits on.

Quick and dirty "legs" can be made from a hex head bolt and two nuts - the nuts sandwich the bottom plate of the amp and the shaft of the bolt gives you some clearance for improved air circulation. Put one set in each corner of the amp.

Quick and dirty "legs" can be made from a hex head bolt and two nuts - the nuts sandwich the bottom plate of the amp and the shaft of the bolt gives you some clearance for improved air circulation. Put one set in each corner of the amp.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- To paint or not to paint - Heatsink Question