Bling!

Every nine months or so, somebody posts a message here complaining about the terribleness of the zinc plated bolts and nuts and washers that make electrical connection between the M2x amp channel PCB and the input stage daughtercard PCB. These folks vow to find a vastly superior replacement. So far, to my knowledge, there hasn't been any follow up.

I myself tried to convince (pay!) a few jewelers and jewelry repair shops, to make me up some M2x hardware plated with either silver, gold, platinum, or rhodium. They always told me this was impossible in the state of California, due to environmental laws & regulations.

Okay, maybe manufacturing is infeasible, but perhaps buying and selling things manufactured elsewhere is allowed. So I occasionally search the web, and I also keep a sharp lookout when I attend craft shows, jewelry shows, art fairs, and similar events.

And now I taunt you, I tantalize you, I tease you with a rather expensive photo ... plus my solemn promise not to provide ANY further explanation. Attached below is a picture of some M3 hardware, lying on my workbench next to my soldering iron. Careful scrutiny will reveal it is the "TORX" star-drive system; not my first choice, but I took what I could get.

Imagine how gorgeous this might look on a black PCB with gold metallization. Perhaps IPS6 or IPS7 or Cedarburg?

That is all.

_

Every nine months or so, somebody posts a message here complaining about the terribleness of the zinc plated bolts and nuts and washers that make electrical connection between the M2x amp channel PCB and the input stage daughtercard PCB. These folks vow to find a vastly superior replacement. So far, to my knowledge, there hasn't been any follow up.

I myself tried to convince (pay!) a few jewelers and jewelry repair shops, to make me up some M2x hardware plated with either silver, gold, platinum, or rhodium. They always told me this was impossible in the state of California, due to environmental laws & regulations.

Okay, maybe manufacturing is infeasible, but perhaps buying and selling things manufactured elsewhere is allowed. So I occasionally search the web, and I also keep a sharp lookout when I attend craft shows, jewelry shows, art fairs, and similar events.

And now I taunt you, I tantalize you, I tease you with a rather expensive photo ... plus my solemn promise not to provide ANY further explanation. Attached below is a picture of some M3 hardware, lying on my workbench next to my soldering iron. Careful scrutiny will reveal it is the "TORX" star-drive system; not my first choice, but I took what I could get.

Imagine how gorgeous this might look on a black PCB with gold metallization. Perhaps IPS6 or IPS7 or Cedarburg?

That is all.

_

Attachments

hi team,

M2X is one of the amp I didn't build yetI love the F6 and Aleph J and the F4 too

Should I consider it ? (I've efficient fostex backloaded horn) - as it seems to be very musical - I read that "between F6 and Aleph J". Any other opinions on this?

Thank you, Fred

Absolutely not!

Totally wrong for your speakers.

Last edited:

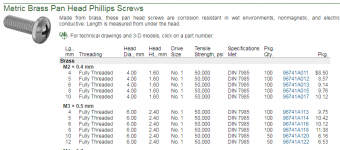

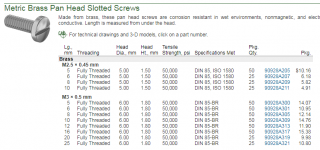

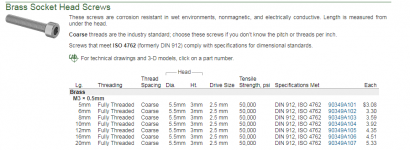

Nah, brass is available in lots of other configurations besides TORX, and it's pretty cheap too. I paid a lot more than what McMaster Carr charges for brass.

_

Brass has higher resistivity that Al, just sayin'.

Mark Johnson,

Good looking hardware, and yes, they will look really nice with a high quality black PCB... go for it!

They must have been thinking, "Precious metal plating on screws... that's a new one!".

In your quest for bling DIY, you've probably provided some mirth for the jewelers.

Good looking hardware, and yes, they will look really nice with a high quality black PCB... go for it!

I myself tried to convince (pay!) a few jewelers and jewelry repair shops, to make me up some M2x hardware plated with either silver, gold, platinum, or rhodium. They always told me this was impossible in the state of California, due to environmental laws & regulations.

They must have been thinking, "Precious metal plating on screws... that's a new one!".

In your quest for bling DIY, you've probably provided some mirth for the jewelers.

Last edited:

TungstenAudio, from Marks description, those are Au... gold (plated?) bolts and nuts.

No, they aren’t.

What did bothered me about the normal zinc plated bolts was not the metal they were made of, but the very fact they were the bolts, loosening on the PCB side and making it difficunt to tighnen them again without removing the PCB, and all the fiddling with the nuts when you wanted to change the buffer.

D-SUB connectors soldered in made it possible for me to easily change the buffers in less than 10 secs and sleep tight at night.

D-SUB connectors soldered in made it possible for me to easily change the buffers in less than 10 secs and sleep tight at night.

- Home

- Amplifiers

- Pass Labs

- The diyAudio First Watt M2x