Sounds interesting - Do you have a more precise prescription or a reference?

First, you need to clean the aluminum product from the top oxide film.

1). To do this, prepare a solution of sodium hydroxide, the proportions: 5-6 grams per 100 ml of water. When mixed, the solution will heat up, but it is better for us when the solution cools down then it is easier to control the reaction rate.

The aluminum part is completely immersed for a short time in a solution of sodium hydroxide. The reaction proceeds violently with the evolution of hydrogen (cautiously!). Time 15-30 seconds, depends on the volume of the part and the concentration of the solution. Do not hold for long - sodium hydroxide "dissolves" aluminum.

2). Then immediately wash in distilled water and leave the water in the water. (Avoid contact with air).

3). We prepare the solution for blackening.

ammonium chloride : 5-15 g.

ammonium orthomolybdate : 10-20 gr.

water : 1000 ml (1 liter).

The temperature of the solution is 80 - 90 degrees C

Depending on the proportion of ammonium chloride and ammonium orthomolybdate, we regulate the color:

more ammonium orthomolybdate - yellow-brown,

more ammonium chloride - more black.

Time 2 - 10 minutes (but maybe longer). At the beginning of processing, the temperature should be high 90 degrees, then can be reduced-it is easier to control the color of the product.

Start working with unnecessary aluminum parts (preferably close in composition to the main part) and when you have good skills you can black out the main detail. Be careful in working with solutions!

Yes, now I also think more about 6E5P. It is easier to provide power and the tube is more accessible.2P29L is what I use , cleaner and much less microphonic than 4P1L . If more gain is required , 6E5P makes a good driver for a hybrid

cheers

316a

Thank you - seems to be worth trying..

First, you need to clean the aluminum product from the top oxide film.

First, you need to clean the aluminum product from the top oxide film.

Yes, the fact is that the ammonium salts react with pure aluminum. A film of aluminum oxide, which is always present in aluminum in the air, prevents this reaction.

Pass DIY Addict

Joined 2000

Paid Member

1). To do this, prepare a solution of sodium hydroxide, the proportions: 5-6 grams per 100 ml of water. When mixed, the solution will heat up, but it is better for us when the solution cools down then it is easier to control the reaction rate.

The aluminum part is completely immersed for a short time in a solution of sodium hydroxide. The reaction proceeds violently with the evolution of hydrogen (cautiously!). Time 15-30 seconds, depends on the volume of the part and the concentration of the solution. Do not hold for long - sodium hydroxide "dissolves" aluminum.

It is worth while to point out that Sodium Hydroxide has a pH of 13

EXTREME caution should be used.

If you are not familiar with working with caustic solutions and ALL of the associated precautions, I would not recommend this process at all... This is NOT a DIY project to be carried out in the kitchen sink

If you are not familiar with working with caustic solutions and ALL of the associated precautions, I would not recommend this process at all... This is NOT a DIY project to be carried out in the kitchen sink

Last edited:

It is worth while to point out that Sodium Hydroxide has a pH of 13

EXTREME caution should be used.

If you are not familiar with working with caustic solutions and ALL of the associated precautions, I would not recommend this process at all... This is NOT a DIY project to be carried out in the kitchen sink

Thank you for the warning, which is correct - I am a pharmacist by training..

well back to the Mofo track - I was just curious about how to make my newly bought alu profile nicer for the Mofo project..

It is worth while to point out that Sodium Hydroxide has a pH of 13

EXTREME caution should be used.

If you are not familiar with working with caustic solutions and ALL of the associated precautions, I would not recommend this process at all... This is NOT a DIY project to be carried out in the kitchen sink

Eric, You are absolutely right! This strong alkali and work with it should be carefully applying all means of protection.

But in everyday life, sodium hydroxide is used, sold both in dry form and in liquid at any household chemical store.

With granular NaOH you can mix it at the concentration you want. Know that it can generate a tremendous amount of heat when dissolvingand can melt a plastic container. Caution is required and I wouldn’t fool with it if you’re not knowledgeable.

The reaction proceeds with the release of heat, I wrote about it above. The temperature is not large for such a proportion - about 38 - 40 degrees C.

The reaction proceeds with the release of heat, I wrote about it above. The temperature is not large for such a proportion - about 38 - 40 degrees C.

Yep. I apologize as I didn’t see your proportion amounts. Just didn’t want anyone getting hurt. After nearly 30 years in labs I’ve seen some inexperienced folks do some very unsafe things.

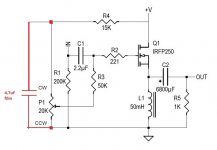

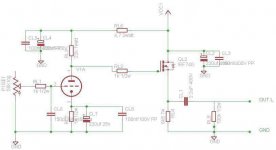

this is my MoFo. I used a simple perfboard to wire the simple circuit kindly suggested by Mr. Rotacher. Maybe I have not been original but the realization using wood and aluminum seen on the pdf presentation I liked a lot. Minimal art .... and simplicity. At the moment I do not have a pre of adequate quality to accompany the MoFo. My DAC (diy) is directly connected to the Mofo with Lightspeed (diy) to adjust the volume. So I do not have the necessary gain to drive the Mofo. I have to provide myself with a preamp suitable for quality and necessary gain. For the power supply at the moment I used the recommended SMPS (19V-DC). I performed the 1.7A bias calibration. The mosfet is the IRFP250.

I have been using MyRef Fremen Ed for years with great satisfaction.

The MoFo sounds wonderfully well. I should repeat words already said by other users that it would be boring to repeat. I can only say that he exhibits one of the best performances I can remember ... and my passion has lasted for 40 years.

After this debut I'm already preparing to go to BigMoFo (193V by Hammond and SMPS MeanWell LRS-200-24).

Thanks to M.Rotacher for sharing a real gem.

I have been using MyRef Fremen Ed for years with great satisfaction.

The MoFo sounds wonderfully well. I should repeat words already said by other users that it would be boring to repeat. I can only say that he exhibits one of the best performances I can remember ... and my passion has lasted for 40 years.

After this debut I'm already preparing to go to BigMoFo (193V by Hammond and SMPS MeanWell LRS-200-24).

Thanks to M.Rotacher for sharing a real gem.

Attachments

Do you think bypass caps make a sound difference on the MoFo?

In my Big MoFo I’m using a pp/film bypass cap with the 6800uF output capacitor. I installed it right from the start, I never compared with/without.

Not ERO MKTNice MoFo mono's Sontero

Are those ERO mkt input caps you're using?

the input cap consists of a Russian k-75-of 1uF + 1 k-73 -PETP of 1uF

@ flocs

@e_fortier

@Vunce

Thanks for the appreciation of the work.

Bypass of the electrolytic cap 6800uF is provided with PP / film. To start I will use Russian cap (I have a stock).

I also thought to place a cap to 4.7uF film to shunt to GND spurious in high frequency that I think can loop back to the gate .... maybe it could be useful. I would like to know if M.Rotacher approves.

Today I tried at home of a dear friend the two MoFo in his system. He was interested in getting to know the Mofos and to me instead check how much a great preamplifier affects performance. My friend owns a Conrad-Johnson Premier 14 (wonderful). Well the Mofo really has an impressive performance. My friend was very impressed and I am convinced that he will soon want to build it for himself.

It is probable that I would use at this point a tube pre accompanied by a buffer (probably a mosfet) to be built as soon as possible.

I had my eyes on other interesting pre (pre LSK by Juma - the Aksa Lender by xrk971- the DCG3 of Salas) to SS. I must decide.

@e_fortier

@Vunce

Thanks for the appreciation of the work.

Bypass of the electrolytic cap 6800uF is provided with PP / film. To start I will use Russian cap (I have a stock).

I also thought to place a cap to 4.7uF film to shunt to GND spurious in high frequency that I think can loop back to the gate .... maybe it could be useful. I would like to know if M.Rotacher approves.

Today I tried at home of a dear friend the two MoFo in his system. He was interested in getting to know the Mofos and to me instead check how much a great preamplifier affects performance. My friend owns a Conrad-Johnson Premier 14 (wonderful). Well the Mofo really has an impressive performance. My friend was very impressed and I am convinced that he will soon want to build it for himself.

It is probable that I would use at this point a tube pre accompanied by a buffer (probably a mosfet) to be built as soon as possible.

I had my eyes on other interesting pre (pre LSK by Juma - the Aksa Lender by xrk971- the DCG3 of Salas) to SS. I must decide.

Attachments

Last edited:

- Home

- Amplifiers

- Pass Labs

- Build This MoFo!