..The noise variety changes depending where the volume is set, with the lowest volume setting having the loudest noise.

The stepped attenuator I have..

At the preamp RCA inputs we find audio signal from source DAC, CD player or audio card etc.

Input RCA center is "hot" (+) wire and another connection in the same RCA is " cold" (-) aka "audio path ground".

This audio GND wire are connected directly to the stepped attenuator ground connection point ,

nothing else , not psu ground yellow green wire.

With a lot of free space inside the enclosure you have many possibilites,

MKP polypropylene 10uF ( in horizontal position under the pcb for example) from Mouser etc.

can be nicer upgrade for ultimate sound quality.

Edit : Cooper colour inside the enclosure are metal foil or just painting ?

Get some metal shielding can quiet noise level

Thanks for all of the reply's.

The copper colour is actually thin copper sheet, that is all grounded to the star ground near the AC power entry.

I generally try and use a single star ground to keep things simple but I'll have to saty I spend my life confused about grounding no matter how much read!

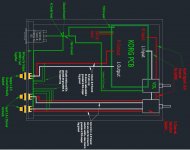

I'm terrible with instruction so I'll do a drawing of how all of the grounds are connected to show the actual setup.

The copper colour is actually thin copper sheet, that is all grounded to the star ground near the AC power entry.

I generally try and use a single star ground to keep things simple but I'll have to saty I spend my life confused about grounding no matter how much read!

I'm terrible with instruction so I'll do a drawing of how all of the grounds are connected to show the actual setup.

..All thoughts welcome

Use different colours stranded wire pairs for internal wiring.

Just do it step by step from B1 Korg build guide,

so many little interesting details about mechanical chassis connections, RCA's together

with audio signal routing and power supply.

You can figure out the principe logic from this process

Look at B1K build video diyAudio Passworks Korg NuTube Preamp Kit Build Tips & Hints - YouTube

Air Gap

I used the included foam between the NuTube and circuit board and my preamp is absolutely dead quiet. I think there is a huge variation between tubes and it just boils down to the luck of the draw.

Please follow 6L6’s B1 Korg Nutube build guide to create an air gap between the Nutube and the PCB.

B1 with Korg Nutube - diyAudio Guides

In my original build, I used the foamed double-sided tape that came with the Korg Nutube. Not sure if this contributed to the microphony, but it sure did ring whenever I turned on the preamp or switched sources.

When I replaced the Nutube with a new one (original was damaged by a lightning strike near my home), I followed 6L6’s build guide and I haven’t had any problems with microphony.

I used the included foam between the NuTube and circuit board and my preamp is absolutely dead quiet. I think there is a huge variation between tubes and it just boils down to the luck of the draw.

.. I will have a play on the weekend.

Power supply inside the chassis can bring transformer mechanical micro vibrations,

pollution with his magnetic field and some heat too.

The kit version external SMPS power supply is a better solution to avoid unwanted noise.

Maybe try how your psu perform outside of the enclosure.

Less noisy ?

Close all air ventilation holes with more copper sheet around.

I bought the Nutube a couple months ago, but still cant figure out why I hear an increased high pitch noise coming from the right speaker. Seems like a capacitor charging and then discharging, actually I need to disconnect the speaker because the sound gets annoying. Does someone experience something similar before?

@ Jtmsrl

In the Mr Pass photo we see the chassis is closed if play music

and don't have any air ventilation holes B1 with Korg Triode

In the Mr Pass photo we see the chassis is closed if play music

and don't have any air ventilation holes B1 with Korg Triode

@ Jtmsrl

In the Mr Pass photo we see the chassis is closed if play music

and don't have any air ventilation holes B1 with Korg Triode

What's weird is that this is just on the right channel and yes, doing all that. I even have a rubber on top of the Nutube

Please follow 6L6’s B1 Korg Nutube build guide to create an air gap between the Nutube and the PCB.

B1 with Korg Nutube - diyAudio Guides

In my original build, I used the foamed double-sided tape that came with the Korg Nutube. Not sure if this contributed to the microphony, but it sure did ring whenever I turned on the preamp or switched sources.

When I replaced the Nutube with a new one (original was damaged by a lightning strike near my home), I followed 6L6’s build guide and I haven’t had any problems with microphony.

I think the new design is smarter. Mine followed the old double side foam tape suggestion. The Nutube is fused to the pcb. It’s like cement. Every vibration is transmitted to the Nutube and the pcb acts like a sail. That air gap looks ideal. I would like to remove my foam tape, not sure how. All is not lost, my Nutube has gotten less sensitive over time.

Maybe try how your psu perform outside of the enclosure.

Less noisy ?

Close all air ventilation holes with more copper sheet around.

Kind regards

The more I think about moving the power supply the more I like it, because I'm about to build my son a new amp I might put the PSU in that amp. Any thoughts on the best power plugs to bring the 24v across?

What is achieved by closing the vent holes?

Non plastic but all metal psu plug from First Watt article

and B1K build guide step 8

and vent holes close is made against microphony step 56

B1 with Korg Nutube - diyAudio Guides

Edit: Mark Johnson two links with pdf articles about wiring of safety earth( ground) , audio grounds ,

ground loops and much more is very useful for Diyers.

Highly recommended The diyAudio First Watt M2x

Thanks Gentelmens

and B1K build guide step 8

and vent holes close is made against microphony step 56

B1 with Korg Nutube - diyAudio Guides

Edit: Mark Johnson two links with pdf articles about wiring of safety earth( ground) , audio grounds ,

ground loops and much more is very useful for Diyers.

Highly recommended The diyAudio First Watt M2x

Thanks Gentelmens

- Home

- Amplifiers

- Pass Labs

- B1 with Korg Triode