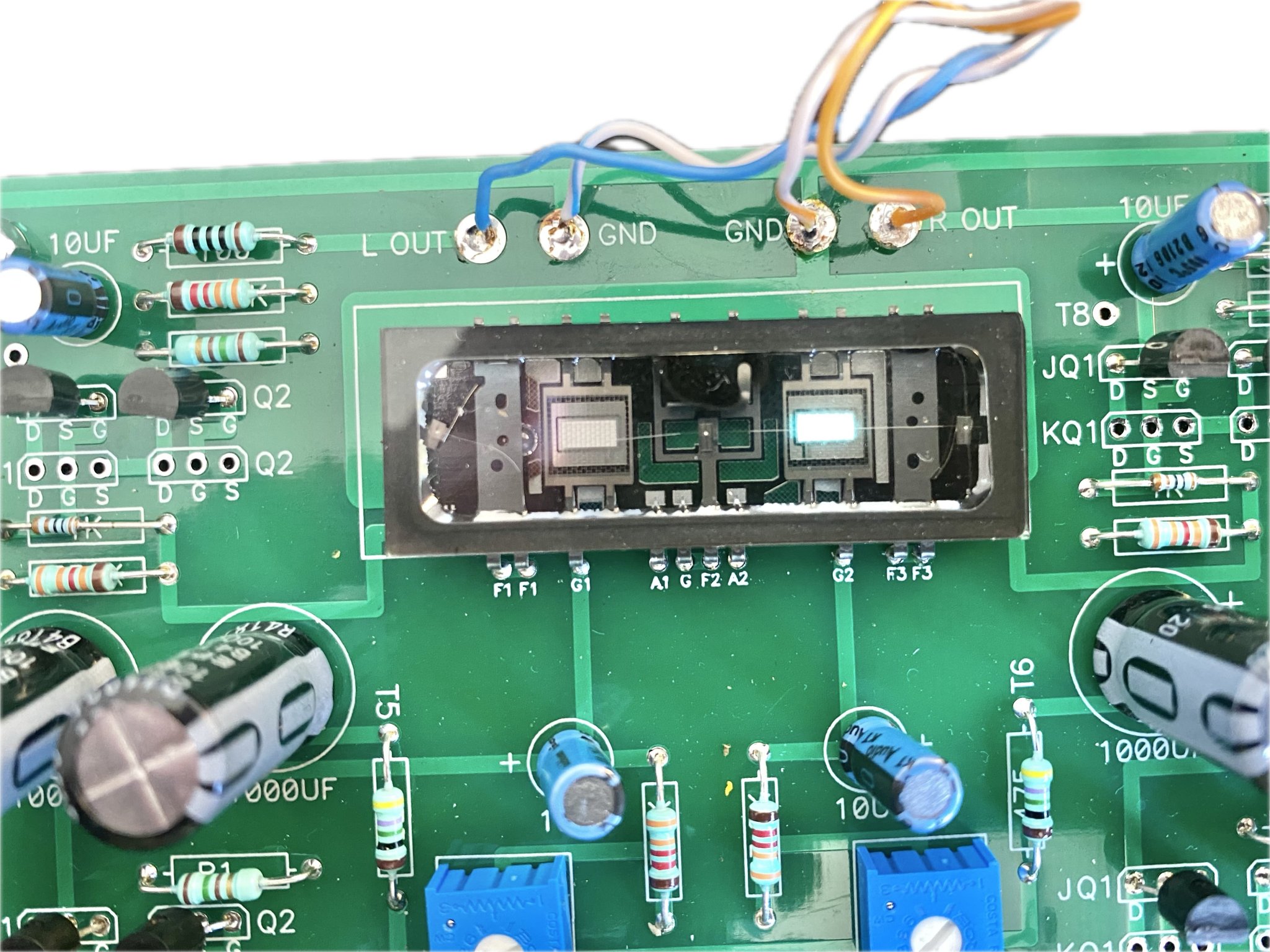

Was working fine with the jumper wire fix but been away for 2 weeks and amp was left on. Came back and only one channel working again. Opened up the back and only one green light on the nutube now...urrrggghhh. What to do?

I had dialled in T7 and T8 to around 9.6V before I left.

Now readings are

T1 23.8 V

T2 23.07 V

T3 22.33 V

T4 9.11 V

T5 9.11 V

T6 0.65 V

T7 20.59 V

T8 9.6 V

I had dialled in T7 and T8 to around 9.6V before I left.

Now readings are

T1 23.8 V

T2 23.07 V

T3 22.33 V

T4 9.11 V

T5 9.11 V

T6 0.65 V

T7 20.59 V

T8 9.6 V

Last edited:

Well that's a big bummer @gwam. You finally get the right channel working and the left fails. It does appear you're going to need a new Korg nutube. Store does have them for $50. The question is why did it fail. Last thing you want to do is swap in a new one only to have that fail due to some other issue. I'm not sure how to figure this one out. More experienced builders will have to chime in.

[Edit]: And the one and only has chimed in. Most excellent!

[Edit]: And the one and only has chimed in. Most excellent!

Last edited:

can't seem to DM probably because you would get hammered with messages! Anyway my address isJust like a tube... I have a spare if you send me your mailing address.

20 Barnett St

Fremantle WA 6160

Australia

Let me know how to reimburse you

Hello everyone, I see others have had similar problems, any recommendations on things I can check to find out why I've blown two NuTubes in my preamp? Far as I know, voltages/biases have measured fine, sound quality has been excellent while working. But twice now, a channel has stopped working permanently, I'm about to plunk another $50 on one of these, but this is going to be my last one. They're also MEGA microphonic, both of them have been, right out of the box, like clap from across the room and my speakers are ringing a high frequency for 2 seconds. I love this preamp otherwise, sounds excellent, so I would very much want to mitigate these things if possible. Thank you!

I've replaced my NuTube once, and if that one fails I will not be replacing it again. Quality control appears to be low.

I used a foam mount from @pmillett to help with microphonics and it works very well. Search on eBay for "Anti-vibration mount for Korg nutube 6P1".

I used a foam mount from @pmillett to help with microphonics and it works very well. Search on eBay for "Anti-vibration mount for Korg nutube 6P1".

Last edited:

I ordered my last tube from Japan, and zilch, none, nada, microphonics. Although it was on my custom decouple board. My suggestion is decouple entire board with rubber washers, and use wire to gnd the board to case. Also it's of great importance to use decoupling board for nutube itself, either use pmillet set or make your own (i can post gerbers here when i return home). It will reduce microphonics to minimum. And use something like vibrofiltr to dampen the case if issues persist. In theory, it will also improve nutube life.

You can see here how i've done it on my custom board, see yellow rubber washers, at post #8420. Those are trough hole and dampen below and above pcb. You can use any regular rubber washer to do the same.

You can see here how i've done it on my custom board, see yellow rubber washers, at post #8420. Those are trough hole and dampen below and above pcb. You can use any regular rubber washer to do the same.

Just checking in to report I'm still using and enjoying my Korg B1. In daily use since about the middle of 2022. I had one or two build problems stemming from my own vision (picking the wrong component.) It's travelled in checked luggage on a few long international flights. Still solid.

I'm going to send this out, shall I address you as GWAM?can't seem to DM probably because you would get hammered with messages! Anyway my address is

20 Barnett St

Fremantle WA 6160

Australia

Let me know how to reimburse you

I commented much earlier about apparent lack of QC by Korg, but ultimately concluded that nothing can be definitively determined. As I am thinking this through, another possibility is that electrical surges in the AC mains may result in transients in the filament/heater that cause it to fail prematurely. But, I do not know if it even possible for such surges to be propagated through a switched power supply. Is anyone knowledgeable about switched PS design that they could comment on my supposition (not a theory).

I agree that early failure of an expensive component is very aggravating. But in all fairness, possible failure mechanisms associated with construction and use need to considered and evaluated.

I agree that early failure of an expensive component is very aggravating. But in all fairness, possible failure mechanisms associated with construction and use need to considered and evaluated.

Microphonics on my NuTube made it virtually unusable much of the time, so it has been in the closet for a long time. It was one of the early kits of only board, NuTube and JFETs.

I did place the eraser on top with double-sided tape as 6L6 suggested. I'm getting ready to update the unit, and will need to de-solder the NuTube and place one of Pete M's devices on it, use the rubber washers to hold up the PCB, as well as cover slots in the top and bottom of the case.

I sure wish Korg would make the NuTube units less prone to microphonics.

I did place the eraser on top with double-sided tape as 6L6 suggested. I'm getting ready to update the unit, and will need to de-solder the NuTube and place one of Pete M's devices on it, use the rubber washers to hold up the PCB, as well as cover slots in the top and bottom of the case.

I sure wish Korg would make the NuTube units less prone to microphonics.

Hi dtaylo3

I had the same problem as you. Due to microphonics I found myself flying through the room to save the tweeters of my loudspeakers.

Had fixed the nutube with doublesided tape. I was about to throw the project into the dustbin. Then...

1. I remembered an early mail from N. Pass who had fixed the nutube with hotglue to the pcb. UUHHH - not at all audiophile. I had nothing to loose. I could not remove the doublesided tape but I fixed the nutube with hotglue.

2. In 1-Euro shop I bought a plastic container for food and mounted the nutube inside. No rubber washers, just solid screws into the wooden mounting plate.

The result? I can tab - no I can drum - with my fingers on the plastic container. Nothing happens. No mycrophonics, no tapping sound from the loudspeakers, just music.

And the sound? I have a Khozmo shunt passive attenuator which sounds very clean and precise. With the B1 Nutube the sound transformed into something new and juicy. Never thought this thing would sound that good.

Give it a try!

I had the same problem as you. Due to microphonics I found myself flying through the room to save the tweeters of my loudspeakers.

Had fixed the nutube with doublesided tape. I was about to throw the project into the dustbin. Then...

1. I remembered an early mail from N. Pass who had fixed the nutube with hotglue to the pcb. UUHHH - not at all audiophile. I had nothing to loose. I could not remove the doublesided tape but I fixed the nutube with hotglue.

2. In 1-Euro shop I bought a plastic container for food and mounted the nutube inside. No rubber washers, just solid screws into the wooden mounting plate.

The result? I can tab - no I can drum - with my fingers on the plastic container. Nothing happens. No mycrophonics, no tapping sound from the loudspeakers, just music.

And the sound? I have a Khozmo shunt passive attenuator which sounds very clean and precise. With the B1 Nutube the sound transformed into something new and juicy. Never thought this thing would sound that good.

Give it a try!

- Home

- Amplifiers

- Pass Labs

- B1 with Korg Triode