Many high end speaker voice coils use CCAW (copper coated aluminum wire) because it conducts well and is light - to keep moving mass low.

Take for example, the ScanSpeak Illuminator midrange ($275) "uses CCAW ribbon wire on a titanium bobbin..."

Scanspeak Illuminator 12MU/4731T-00 4.5" Midrange - 4 ohm

So you can try to avoid Al all you want, in the end the sound comes out via Al wire.

Take for example, the ScanSpeak Illuminator midrange ($275) "uses CCAW ribbon wire on a titanium bobbin..."

Scanspeak Illuminator 12MU/4731T-00 4.5" Midrange - 4 ohm

So you can try to avoid Al all you want, in the end the sound comes out via Al wire.

Last edited:

I service one type of equipment that uses faston type terminals for several things. I've replaced lots of them for loosening up or becoming oxidized and overheating. They have their uses, but not reliable long term.

But then there are also countless examples of where this connector, when properly spec'd and implemented, such as in HVAC systems, automotive systems, refrigerators, pro-audio amps and speaker systems, etc. where it works fine for 20+ years. For my amps, I have never had an issue. But I have had issues with flying leads.

Last edited:

So you can try to avoid Al all you want, in the end the sound comes out via Al wire.

I like aluminium spades connectors in my coffee machine

I use spades when the thing being connected has a spade lug, and circular

connectors when has a screw. These tend to be power switches and

rectifier bridges. Never had an issue.

I solder when they don't have these - it's easier, and also always works.

Doesn't suffer audio paranoia either.

Exception is speaker driver lugs, where I prefer to solder.

connectors when has a screw. These tend to be power switches and

rectifier bridges. Never had an issue.

I solder when they don't have these - it's easier, and also always works.

Doesn't suffer audio paranoia either.

Exception is speaker driver lugs, where I prefer to solder.

No, they're not. As long as you do it securely, you are allowed to solder mains wiring directly to the board or other parts. But a dab of glue or heatshrink to protect and secure things is always a good idea. Many mains inlets have spade connectors that are allowed to be used as solder tabs. Check the datasheet of the part though.I believe spade connectors are only mandatory on mains connections.

In household appliances it's spade connectors galore. Even more fancy looking connector blocks have spades hidden in them. Sometimes they give problems, often due to moisture and heat (dishwashers and washing machines), but those are circumstances where many other connectors also give problems. If you run into problems with them in DIY audio, check for traces of spilled beer. They're generally trouble free in dry environments.

I agree with the idea of equipping boards with generic connector types. If you don't like them, you can always solder wires directly to the board, or use the spades as solder tabs. I think it is more an issue of avoiding inconvenience during board design that they are left out. Many DIY layouts simply look unfinished to me, adding appropriate connectors sure counts as a finishing touch in my book. Even when you intend to produce thing that are intended to never be taken apart, connectors help with assembly and reduce the chance for errors. Commercial stuff with wires soldered directly to the board are usually bottom-of-the-barrel cheap thingamabobs.

Screw terminals work much better when you crimp an end sleeve over stranded wire.

I use these Belleville washer - Wikipedia

Yeah, I should switch to those -- they have a bit more spring pressure than waves.

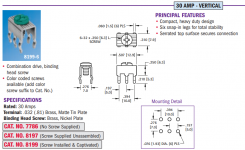

The Power Supply Soft Start Board V.3, sold in the diyAudio store, uses the extremely nice "Keystone 8197" connector. Picture below, link to Mouser sales page

It's rated for 30 amperes, it's got six leads, it's got a screw terminal where you can attach either bare wire (boo!), or spade lugs (meh), or ring connectors (yay!).

_

It's rated for 30 amperes, it's got six leads, it's got a screw terminal where you can attach either bare wire (boo!), or spade lugs (meh), or ring connectors (yay!).

_

Attachments

if you want to build them that way , be my guest

also - I'm my own guest, if I don't want to build in that way

so - everyone is happy

It's simple isn't it.

I've had plenty of them fail. Admittedly in one of my other hobbies (old cars) where the operating conditions are considerably more dire.

were poor right off the assly line. Impossible to argue that.

Note though that those were Not quite the same part nor fitted into conditions normally found in an Amp.

Personally I'm less than enamoured by those Green blocks with screw connectors one usually sees on Ebay Chi Fi contraptions.

We all have prejudices

Exception is speaker driver lugs, where I prefer to solder.

Thank you Nelson.

This is what I also do.

Even when you intend to produce thing that are intended to never be taken apart, connectors help with assembly and reduce the chance for errors. Commercial stuff with wires soldered directly to the board are usually bottom-of-the-barrel cheap thingamabobs.

Behold the Threshold NS-10 preamplifier designed by Nelson Pass. The red and blue wires at bottom right, connect the AC mains (IEC inlet) to the PCB.

_

Attachments

Behold the Threshold NS-10 preamplifier designed by Nelson Pass. The red and blue wires at bottom right, connect the AC mains (IEC inlet) to the PCB.

There are exceptions of course... This is clearly done to avoid making audiophiles nervous by having too many connectors in the "signal path"...

The way the IEC connector is wired is perfectly acceptable from a safety viewpoint. Repairing this thing is going to be cumbersome because of the many solder joints that have to be undone before the board can be taken out.

The biggest problem with a spade terminal is that its electrical fuction (solder conductivity to the PCB) and mechanical fuction (solder holding it on the PCB) are not separated. It is not able to withhold much stress, the solder joint will break after a couple of connection cycles. Sometimes it happens by itself, if the thermal expansion constant is different from that of the solder. A hardly visible crack may occur that is very difficult to troubleshoot.

This is a problem shared with many components which are heavy or in another way subjected to mechanical loads. Think of any type of connector, heavy transformers, switches, encoders and pots and whatnot. Also parts that double as board mounts have this issue, think of boardmount RCA connectors that have a screw for mounting it to a panel. The board is then supported by the connector, and thus ultimately from its solder joints. A similar thing happens with some BNC connectors.

A good way to deal with this is to always use a double sided PCB, and solder the thing on both sides. Also, take care of sufficient copper area around the part on both sides. Ultimately, it is the adhesive between board and copper that keeps the part in place.

A good way to deal with this is to always use a double sided PCB, and solder the thing on both sides. Also, take care of sufficient copper area around the part on both sides. Ultimately, it is the adhesive between board and copper that keeps the part in place.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Why the Hate for Spades?