Liquid cooled Class A amp

Hi everyone,

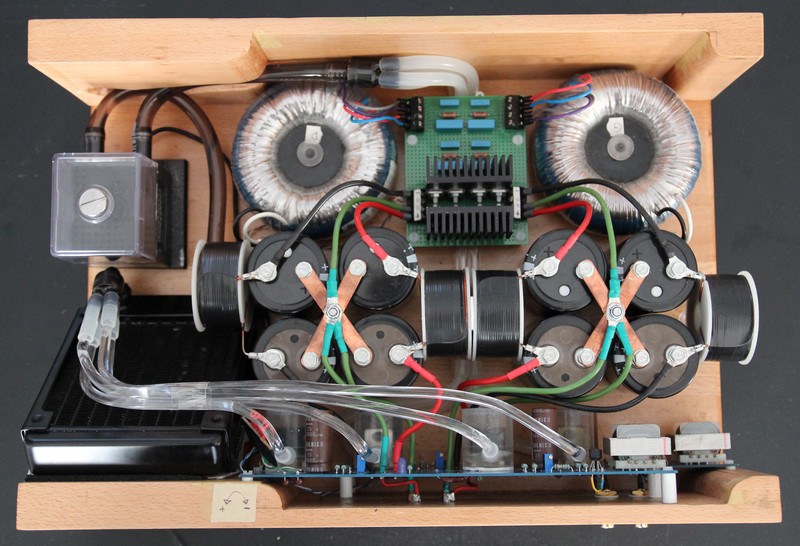

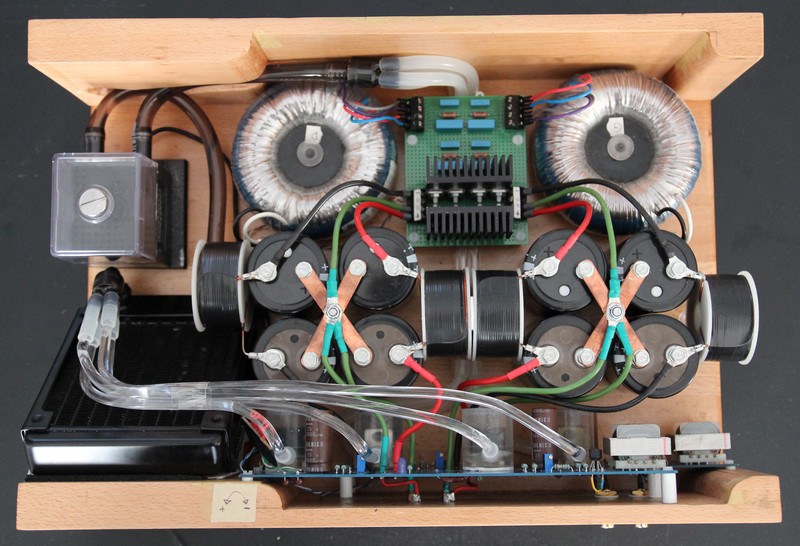

this is my liquid cooled amplifier , made with Pass F6 boards from the Diyaudio store

it took me 6 months to desing and build it , Bias is 0.550 v , and supply is 24.5 v , they are quite steady .

Power supply is CLC type with 5 mv ripple for each rail , and DC offset is about -5/+5 mv .

Components are the best available for such make , and the result is what i was looking after .

this amp is dead quiet , and the sound is nearly perfect ( to my ears !!)

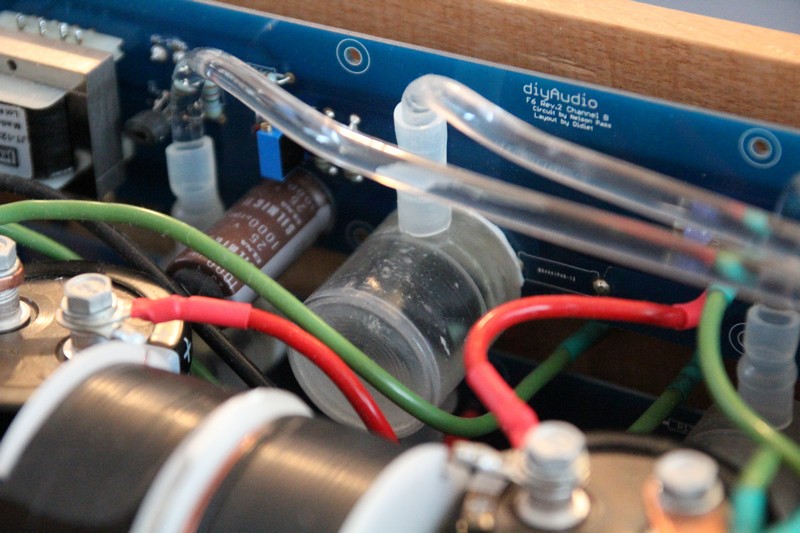

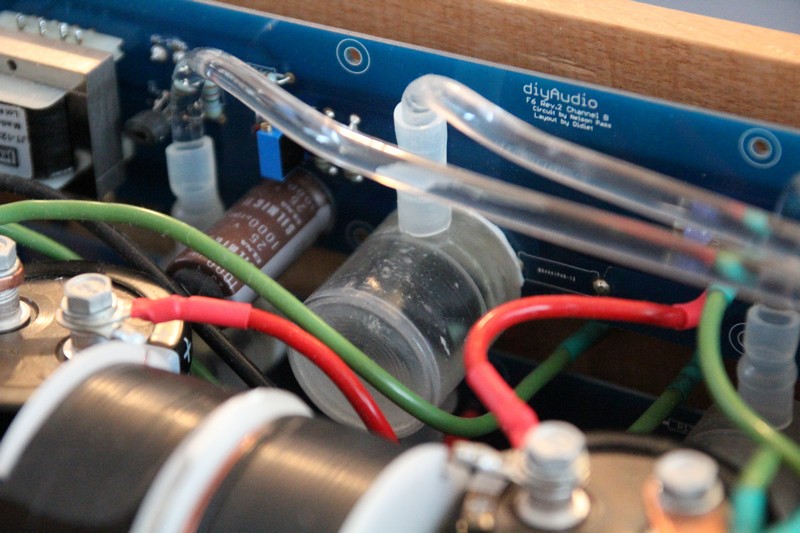

the Mosfet are in the water , and their temperature is 17 °c over the room temp .

fan and water pump are noiseless .

it gave me his best after about 20 hours running in , since that it's all pleasure ;-)

a nice wooden chassis to avoid any kind af interferences .

and , most important , the less wire as possible .

here are some pics

.

Hi everyone,

this is my liquid cooled amplifier , made with Pass F6 boards from the Diyaudio store

it took me 6 months to desing and build it , Bias is 0.550 v , and supply is 24.5 v , they are quite steady .

Power supply is CLC type with 5 mv ripple for each rail , and DC offset is about -5/+5 mv .

Components are the best available for such make , and the result is what i was looking after .

this amp is dead quiet , and the sound is nearly perfect ( to my ears !!)

the Mosfet are in the water , and their temperature is 17 °c over the room temp .

fan and water pump are noiseless .

it gave me his best after about 20 hours running in , since that it's all pleasure ;-)

a nice wooden chassis to avoid any kind af interferences .

and , most important , the less wire as possible .

here are some pics

.

Last edited:

Looks really neat ...congratulations.. Tell me how did you encapsulate the outputs...was thinking about some of same ideas for my AMP project cause its forced air cooled and not at all Quiet ... Was considering cnc made water blocks.. But have no acces to the machinery unfortunatly... But again vers Nice building.. Set some thoughts here

Nice work. You weren't kidding, the outputs are literally in the water.

I have wanted to make a redneck (American colloquialism for a low tech country-boy implementation) version of a water cooled class A amp by bolting the outputs to the outside of an aluminum (cook) pot/pan of water. Have a system to auto add water level and the water heats up and evaporates. Size is large enough so never boils - want to keep warm below 50C or whatever.

The outputs here are not in the water so less care has to be taken and the chances for leaks (other than tipping pot over) are nil. Won't look as cool though of course.

I have wanted to make a redneck (American colloquialism for a low tech country-boy implementation) version of a water cooled class A amp by bolting the outputs to the outside of an aluminum (cook) pot/pan of water. Have a system to auto add water level and the water heats up and evaporates. Size is large enough so never boils - want to keep warm below 50C or whatever.

The outputs here are not in the water so less care has to be taken and the chances for leaks (other than tipping pot over) are nil. Won't look as cool though of course.

Electrolysis through the water could cause some interesting failures, I would think electrical isolation between the transistor and water would ruin the benefits of water cooling? Unless the P and N outputs were on different water lines? Also dissimilar metals in contact with each other and the water would also cause electrolysis like in water heater anodes.

If parts in contact with water are all of similar metal and deionized water is used, should work well and not have electrolysis issue or electroplate issue. High voltage flashlamps for lasers (3 to 10kV and many amps) routinely run submerged in DI water for cooling. A deionizer packed bed filter is often in loop to ensure that the water stays relatively ion-free (Mohms). Problem arises when disimilar metals are used (brass, zinc, copper, stainless steel, aluminum, etc.)

The water used is bi-distilled , it has 2 Mohms/cm résitivity , mosfets drains are distant 30 cm to each others , no issues at all ;-)

the water "chambers" are made in polycarbonate , sealed with flexible epoxy , no leaks.

I forgot to Tank's Mr Nelson Pass for his awesome amps ;-) , that works great no matter what cooling you use

.

the water "chambers" are made in polycarbonate , sealed with flexible epoxy , no leaks.

I forgot to Tank's Mr Nelson Pass for his awesome amps ;-) , that works great no matter what cooling you use

.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- liquid cooled F6