If you use search you can see that this topic pops up time after time. I am a bit bored at work, so I decided to crate this thread, so it maybe be useful for a new DIYers.

So, thermal conductivity what it is and how to change among many insulators on the market?

Thermal conductivity is a number which characterizes ability of a material to conduct heat. Based on empirical Fourier law for homogeneous media,

thermal conductivity is equal to amount of heat going through a unit area of a material per unit of time at a given temperature gradient (K/m in SI) across the sample.

Thus, we want this coefficient to be as big as possible! As close to one of aluminum (~200 in SI units).

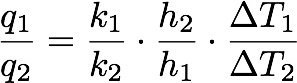

So, how to compare? - Simple! Just assume that we are satisfied with the Fourier expression, than:

Just plug in the numbers from data sheets for thermal conductivities k_i and pad thicknesses h_i and calculate .

.

There is a tricky question with the temperature difference delta T(between transistors case and heatsink) as it will be smaller for the pad with bigger k. However, even simple estimations will show you that (fortunately or unfortunately) there is not so much difference between different pads on the market! The best is Beryllium oxide (thermal conductivity is close to aluminum), but toxic and impossible to find, but all others -- almost the same. REMEMBER, I AM TALKING ABOUT GOOD STUF: Kapton, sill-pad A2000, aluminum oxide, etc.

So if you are new in the field and choosing, pick something and start building already!

Another important thing: air has pretty bad thermal conductivity, so you want to use a thermal grease to fill in roughnesses between your solid surfaces and the pad. OR, use sil-pad a2000( mouser and digikey have them), they are soft and do not require any grease. That what I do and result is good.

Hope it helps

So, thermal conductivity what it is and how to change among many insulators on the market?

Thermal conductivity is a number which characterizes ability of a material to conduct heat. Based on empirical Fourier law for homogeneous media,

An externally hosted image should be here but it was not working when we last tested it.

thermal conductivity is equal to amount of heat going through a unit area of a material per unit of time at a given temperature gradient (K/m in SI) across the sample.

Thus, we want this coefficient to be as big as possible! As close to one of aluminum (~200 in SI units).

So, how to compare? - Simple! Just assume that we are satisfied with the Fourier expression, than:

An externally hosted image should be here but it was not working when we last tested it.

Just plug in the numbers from data sheets for thermal conductivities k_i and pad thicknesses h_i and calculate

There is a tricky question with the temperature difference delta T(between transistors case and heatsink) as it will be smaller for the pad with bigger k. However, even simple estimations will show you that (fortunately or unfortunately) there is not so much difference between different pads on the market! The best is Beryllium oxide (thermal conductivity is close to aluminum), but toxic and impossible to find, but all others -- almost the same. REMEMBER, I AM TALKING ABOUT GOOD STUF: Kapton, sill-pad A2000, aluminum oxide, etc.

So if you are new in the field and choosing, pick something and start building already!

Another important thing: air has pretty bad thermal conductivity, so you want to use a thermal grease to fill in roughnesses between your solid surfaces and the pad. OR, use sil-pad a2000( mouser and digikey have them), they are soft and do not require any grease. That what I do and result is good.

Hope it helps

Thanks for posting on this topic PKI as I am sure that it will help many new to the hobby with this issue!!!

I've been doing this stuff from back when we had to use whale blubber for grease and have discovered the best way to avoid the heat sink problem is to use tubzzzzz....

and have discovered the best way to avoid the heat sink problem is to use tubzzzzz....

I've been doing this stuff from back when we had to use whale blubber for grease

and have discovered the best way to avoid the heat sink problem is to use tubzzzzz....

and have discovered the best way to avoid the heat sink problem is to use tubzzzzz.... That type embedded link, you really have to right-click and "Open in new Tab".

An additional problem: they are really stored on a TapATalk server which has a defective security certificate (expired).

Pictures -- Why Not attach Them ??

An additional problem: they are really stored on a TapATalk server which has a defective security certificate (expired).

Pictures -- Why Not attach Them ??

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.