We've added just the parts kit- including the PSU's, back on the order page so people who don't want to pay for shipping the chassis to their country have an option. I believe that if you add up all the bits and pieces it is price competitive with small quantity orders of parts at Digi-Key or Mouser. And if not, certainly when you count the time to make up an order!

Hi

Just to inform any one living in EU and having a hard time getting there bits and pieces.

Try DIGIKEY´s site.

Normally I would not advertice for anyone,but compare the product index,prices and shipment terms/price.

Just ordered the parts for the ACA and some for the PLH.

Waiting for that magic moment: "Your order has been send"

Jan

PS:

Meant the parellel version of the PLH.

Last edited:

ACA dual mono power supply

To see what it sounds like, I am going to build a dual mono ps for my ACA's just because I have a bunch of capacitors and a pair of Antek 50VA 15VAC transformers lying around. With a 1ohm load I am not sure what exactly the rail voltage will be. Would it matter if the voltage is closer to 20VDC than 19VDC? If so, should the voltage on Q1 be adjusted a little higher than 10VDC?

To see what it sounds like, I am going to build a dual mono ps for my ACA's just because I have a bunch of capacitors and a pair of Antek 50VA 15VAC transformers lying around. With a 1ohm load I am not sure what exactly the rail voltage will be. Would it matter if the voltage is closer to 20VDC than 19VDC? If so, should the voltage on Q1 be adjusted a little higher than 10VDC?

Hi

Jan

I really would haved liked to order a kit but unfortunally the price for a kit from US,send to Denmark is ridiculus,not blaming aca,its the shipment and on top 25% danish tax.The pcbs alone at 20$ will end up near to 60$

Jan

The distortion at 1W changes quite a bit as you adjust the pot. I documented this earlier in this thread as far as distortion plots will show. A serious listening test is the only way to determine what you will like. Changes as small as 1V are easily measurable.

agree with that

my comment was about difference between 19 and 20V PSU , while setting procedure remains the same

Pass DIY Addict

Joined 2000

Paid Member

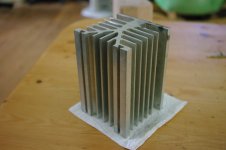

I would think that sink is perfect for one channel. My guess is that it might run a bit cool.

My guess is that it will run hot with the 20 Watts dissipation.....

would this heatsink be enough for one channel?

size is 12 X 8 X 8 CM backplate is 7 or 8 MM

I think you will be fine. Mount the transistors close to that big meaty part that runs up the center and near the bottom. If you can arrange things to let air enter the bottom, that would be a big plus.

I think you will be fine. Mount the transistors close to that big meaty part that runs up the center and near the bottom. If you can arrange things to let air enter the bottom, that would be a big plus.

i have some 6MM copper plating left over, maybe that would help distribute the heat?

my plan was to put the transistors near the center in height one above the other leads to the side instead of down.

Pass DIY Addict

Joined 2000

Paid Member

my plan was to put the transistors near the center in height one above the other leads to the side instead of down.

Exactly! Sink the transistor mounting screws directly into that thick vertical vein. No need for the copper.

Pass DIY Addict

Joined 2000

Paid Member

Yup, that's what I meant! It might make things easier to just mount the transistors with a bit of space between them so the PCB sits right on top of them - this way you won't need extra wiring...

Given the thickness of that sink, you won't have any problems with heat spreading. If you can raise that sink up off of the table with your final implementation to allow some airflow through those fins as has already been suggested, it will work much better.

Given the thickness of that sink, you won't have any problems with heat spreading. If you can raise that sink up off of the table with your final implementation to allow some airflow through those fins as has already been suggested, it will work much better.

build in to the design i have in mind the heatsink will have about 2cm clearence from the underside. on the upperside there will be wiremesh. my son will not be using PCB but point to point. this is going to be his first amp. although he did solder a portion of the work on my aleph 5 mono's two weeks ago.

it will be a dual mono design with 3 inputs and a passive pre-amp.

all point to point on a solid coper frame polished to a high gloss shine with a clear cover and a hard stone front.

it will be a dual mono design with 3 inputs and a passive pre-amp.

all point to point on a solid coper frame polished to a high gloss shine with a clear cover and a hard stone front.

Pass DIY Addict

Joined 2000

Paid Member

3cm should not be a problem.

i can place the heatsinks on top of the bottom plate instead of behind it, that will give me just over 1cm extra.

don't worry, i will post pictures of the progress.

only not under this name, i'll give my son his own account here and i think he whill be the youngest active member here.

the chassis i will make myself doe to the use of power tools. all the soldering will be done by my son, this will be his birthday present this year only, he is going to get it about 6 weeks early.

i can place the heatsinks on top of the bottom plate instead of behind it, that will give me just over 1cm extra.

don't worry, i will post pictures of the progress.

only not under this name, i'll give my son his own account here and i think he whill be the youngest active member here.

the chassis i will make myself doe to the use of power tools. all the soldering will be done by my son, this will be his birthday present this year only, he is going to get it about 6 weeks early.

- Home

- Amplifiers

- Pass Labs

- Amp Camp Amp - ACA