Stepped drill bits are great for drilling larger holes in aluminum. The largest bit in my set is 19mm but I have seen them as large as 35mm. These bits drill perfect circles in aluminum and thinner steel. I have used them to drill ventilation holes in bottom panels, connector holes in back panels, and holes for round led switches in front panels.

Another very useful drilling tool if you don't have a drill press is a drill guide. I use a drill guide to help in drilling and tapping heat sinks. It keeps the drill bit and tap perpendicular to the surface of the heat sink. It requires a bit more work but I don't have much choice since I have no room to store a drill press.

Another very useful drilling tool if you don't have a drill press is a drill guide. I use a drill guide to help in drilling and tapping heat sinks. It keeps the drill bit and tap perpendicular to the surface of the heat sink. It requires a bit more work but I don't have much choice since I have no room to store a drill press.

Attachments

I will try it. I remember another tool which can be used for making large holes in soft metal. But I can't remember the name. The tube-guys used it for making large holes for tube sockets etc. Typical in aluminium. As I remember it....it worked with high presure and was more a cut/clip tool than a saw or drill tool. It was al by hand (not an electric tool as I remember it). It made very nice and accurate cut holes.

I remember it as this tool (go down to picture 23, 24 and 25):

How to Layout and Build a Guitar Amplifier Chassis - GuitarKitBuilder

On the way down we also see the stepped drill bit in action.....but for the larger holes the speciel press and cut tool is used…...all by hand. The "bits" are special ones with arched knives.....I like this tool…..

How to Layout and Build a Guitar Amplifier Chassis - GuitarKitBuilder

On the way down we also see the stepped drill bit in action.....but for the larger holes the speciel press and cut tool is used…...all by hand. The "bits" are special ones with arched knives.....I like this tool…..

@Meper

most types of aluminium can easily be cut with tools you'd use for wood

e.g. jigsaw, circlesaw, drill, ...

watch out for shrapnels!

A.

...and wear ear defenders...the noise can be really nasty!

Pass DIY Addict

Joined 2000

Paid Member

Aleph Integrated Amp.

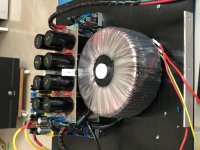

A Friend requested that I helped build an integrated amp for him. I selected the Aleph Clone. Four output pairs per channel. With 1.6A bias per channel so it does not run too hot. The chassis was not very big with smallish heatsink. Dual mono supply with 1KVA transformer and separate secondaries for each channel. Sounded gorgeous.

A Friend requested that I helped build an integrated amp for him. I selected the Aleph Clone. Four output pairs per channel. With 1.6A bias per channel so it does not run too hot. The chassis was not very big with smallish heatsink. Dual mono supply with 1KVA transformer and separate secondaries for each channel. Sounded gorgeous.

Attachments

...this is ACA I made today... Thanks Nelson.

I'm not up to date.

Would you be so kind and tell what is 'ACA' ?

The very popular Amp Camp Amp

Thank you very much!

Very elegant, simple and perfectly explained by Mr. Nelson Pass.

Kind Regards,

Andrzej

Since this is pics thread...this is ACA I made today, we got snow day. This is my 4th ACA. Sounds sweet. Thanks Nelson.

Is that foamcore board? Do you have cornu spirals too?

- Home

- Amplifiers

- Pass Labs

- Pictures of your diy Pass amplifier