Daddy told me that can a reason could be that attaching them to a vehicle chassis makes a nice ground point for a single rail + supply, but what if someone wants to make a +/- supply? Is there a version of the capacitor with the + side tied to the bolt?

I use to test with low amperage fast burn fuses in series, first time I forget to fit them, first time I made a PSU fail.no.

you cracked the diodes, because you chose to power up direct on line.

Use a bulb tester every time you modify or test a new mains project

I think the Forum should introduce a new rule.

Every Member that uses direct on line starting of any modified mains powered equipment and posts the terrible results, shall be publicly ridiculed by every other Member who reads that tale of woe !!

BTW, I have just asked in another Thread why the Member broke the Forum Rule and quoted the whole of my post.

You as a Moderator should know better.

That's a poor example of behaviour and now you can report me for discussing Moderator behaviour.

Every Member that uses direct on line starting of any modified mains powered equipment and posts the terrible results, shall be publicly ridiculed by every other Member who reads that tale of woe !!

BTW, I have just asked in another Thread why the Member broke the Forum Rule and quoted the whole of my post.

You as a Moderator should know better.

That's a poor example of behaviour and now you can report me for discussing Moderator behaviour.

Last edited:

The F6 design is complete, and I simply

need to stuff the pc boards that I designed so that you can see spiffy

finished product, and then I need to write the article.

Provided that we all post a LOT of messages in the Papa diy devices topics, I would suggest to create sub-forums for the coming F6 baby: one for the power supply, one for the parts, one for the construction tips, etc....

Because this current F5 topic has already reached 1147 pages (!) and it becomes very difficult to find an info...

Just my 2 cents proposal ...

I think the Forum should introduce a new rule .

thorough investigation of vids related :

Monty Python - Spanish Inquisition Torture Scene - YouTube

thorough investigation of vids related :

Monty Python - Spanish Inquisition Torture Scene - YouTube

I discovered the same thing with PEH169's although I was lucky enough not blow anything up.

The RIFA accessories data sheet showed stepped poly washers being used to isolate the stud but I couldn't find any. Ended up drilling the mounting holes a bit bigger and fitting through panel wiring grommets as insulators.

Been working fine for two years in an F4.

The RIFA accessories data sheet showed stepped poly washers being used to isolate the stud but I couldn't find any. Ended up drilling the mounting holes a bit bigger and fitting through panel wiring grommets as insulators.

Been working fine for two years in an F4.

Andrew, were you talking to me? I am not a Moderator...

Agreed, you can ridiculize my failures as much as I do to myself.

For the RIFA solution, I am going with a bigger hole and smaller plastic rings or silicone to fill the hole. The a plastic washer, and probably a metal one above it to provide better stability. Nylon hats for the live protuding bolt will be custom made in a friend's CNC (the amp is being made for him).

Regards,

Agreed, you can ridiculize my failures as much as I do to myself.

For the RIFA solution, I am going with a bigger hole and smaller plastic rings or silicone to fill the hole. The a plastic washer, and probably a metal one above it to provide better stability. Nylon hats for the live protuding bolt will be custom made in a friend's CNC (the amp is being made for him).

Regards,

PSU sizing for F5 monoblocks

Hello guys,

I know that you are used to the silliest questions from newbies, so I dare to ask..

I want to build a couple of F5 monoblocks. The original schematics say 300VA for the trafo, and 4x15000uF 25V caps per rail.

What is the equivalent for the mono version ? Same figures, or half is enough ?

I've seen someone putting 8x18.000uF in a single F5 mono box, so I'm wondering about that.

That said, I want to oversize the PSU a bit. What are in you opinion the maximum values worth to be used, without going to nonsense ? Is a 300VA trafo already more than enough, or should I pick up the 500VA version for some more bucks ? (still speaking about a mono F5 amplifier).

The brands of choice will be Amplimo and Evox-Rifa.

Thanks a lot!

Hello guys,

I know that you are used to the silliest questions from newbies, so I dare to ask..

I want to build a couple of F5 monoblocks. The original schematics say 300VA for the trafo, and 4x15000uF 25V caps per rail.

What is the equivalent for the mono version ? Same figures, or half is enough ?

I've seen someone putting 8x18.000uF in a single F5 mono box, so I'm wondering about that.

That said, I want to oversize the PSU a bit. What are in you opinion the maximum values worth to be used, without going to nonsense ? Is a 300VA trafo already more than enough, or should I pick up the 500VA version for some more bucks ? (still speaking about a mono F5 amplifier).

The brands of choice will be Amplimo and Evox-Rifa.

Thanks a lot!

Cap Nuts alone do not solve the problem of a "Live" screw terminal.

You would also need an insulated top hat style shouldered washer and an oversize mounting hole.

The cap nuts have a built in shoulder which provide the necessary insulation providing you make the hole the correct size.

Hello guys,........

Thanks a lot!

you already know what's stock FW variant

use same amount for one channel , and you're good

These are great news!! Thank you so much!The cap nuts have a built in shoulder which provide the necessary insulation providing you make the hole the correct size.

Regi,

I appreciate you alerting us about your problem and how these stud mount Rifa's are connected. I had not realized that and would have made the same error. I'm currently in the middle of a pair of monoblocks for my F5/BA-1/BA-3/whatever.. dreams. So, a total of 8 of these PEH200's with a nice heavy short right to the chassis. Now floating on rubber grommets so all should be well... Thanks again.

William

I appreciate you alerting us about your problem and how these stud mount Rifa's are connected. I had not realized that and would have made the same error. I'm currently in the middle of a pair of monoblocks for my F5/BA-1/BA-3/whatever.. dreams. So, a total of 8 of these PEH200's with a nice heavy short right to the chassis. Now floating on rubber grommets so all should be well... Thanks again.

William

Note that the near short circuit current requires only 3.8Vpk to drive that 0r1 load. That is an output power of 72W.

You would need to test the amp into 0r6 and find out what voltage peak it can maintain.

If it is truly rated to drive that load then the voltage should remain fairly high. Certainly no less than 50% of the high load resistance output voltage and preferably >70% of the high load resistance voltage.

Short circuit current tells us nothing about speaker driving capability.

Vpk into resistive load, near speaker load, tells us much more.

Short circuit current can be used to assess what the protection systems could potentially do to valid audio signals.

Happy Boxing day to you Andrew..

I was thrown off by papa's 38amp figure ...

Hi all I have a question about setting up the F5 the initial adjustment section says to adjust the pots so that you have 0.59V across R11 and R12.

What I have is .5858V on R11 and 0.5848 across R12, and this gives me 2.4mv at the output (I aimed to get the output voltage as low as possible).

So my question is do I set the voltage across R11 and R12 to be exactly the same and see what I get at the output or are the settings I have fine ?

The amp has been running unloaded (no speaker connected) for 4 hours and the heats sink is 54 degrees and stable (for 3 hours)

PS the heat sink gets vey hot I would hardly believe the 2 fets can put out so much heat (the heat sink is 220mm wide 250mm high and 70mm deep with a mounting thinkness of 10mm , the weight is 5Kg)

What I have is .5858V on R11 and 0.5848 across R12, and this gives me 2.4mv at the output (I aimed to get the output voltage as low as possible).

So my question is do I set the voltage across R11 and R12 to be exactly the same and see what I get at the output or are the settings I have fine ?

The amp has been running unloaded (no speaker connected) for 4 hours and the heats sink is 54 degrees and stable (for 3 hours)

PS the heat sink gets vey hot I would hardly believe the 2 fets can put out so much heat (the heat sink is 220mm wide 250mm high and 70mm deep with a mounting thinkness of 10mm , the weight is 5Kg)

Last edited:

goal is to be in ballpark regarding Iq , and as low as possible with DC offset on output ;

you're measuring voltage across one source resistor (to monitor Iq) , and voltage across output (against gnd) , to monitor output offset .

you don't need to care for voltage across other source resistor , except to measure it as quick check is it everything OK

these two voltages ( across two source resistors) can be equal only in ideal situation - when both source res are identical , and both mosfets are identical

in any case - you're good with present values - 100mV is tolerable , everything under 20mV is good enough - speaking of output offset

you're measuring voltage across one source resistor (to monitor Iq) , and voltage across output (against gnd) , to monitor output offset .

you don't need to care for voltage across other source resistor , except to measure it as quick check is it everything OK

these two voltages ( across two source resistors) can be equal only in ideal situation - when both source res are identical , and both mosfets are identical

in any case - you're good with present values - 100mV is tolerable , everything under 20mV is good enough - speaking of output offset

The heat sink gets vey hot I would hardly believe the 2 fets can put out so much heat (the heat sink is 220mm wide 250mm high and 70mm deep with a mounting thinkness of 10mm , the weight is 5Kg)

Hard to estimate the adequacy of your specific heatshinks...will depend upon the fin design and orientation, among other parameters. Are the sinks mounted so that the fins are vertical (i.e., can they fins create and take advantage of convective thermal flow)? Do you have the thermal dissipation spec for your specific heatsinks?

Without taking analytical measurments (unless you have an IR thermometer, etc....) the "rule of thumb" is--can you leave your hand on the heatsinks for five seconds, without removing due to pain....? (Of course, your pain threshhold may vary....!)

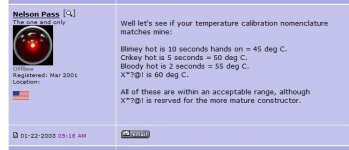

Seems like my "very hot" is equal to Papas "Bloody Hot". I will have to test some forced cooling options as we have a youg kid in the house.

My comment was more to the issue of how I am amazed that these 2 small devices can create so much heat and still keep the smoke in.

Thanks for the pointers - maybe when I am done I can post the reults ( convection and forced cooling) to help any future new constructors , as I have noticed that heat sinking is a common cause of questions.

And for the F5 turbo seems like we are going to need some serious heat sinks for that one.

My comment was more to the issue of how I am amazed that these 2 small devices can create so much heat and still keep the smoke in.

Thanks for the pointers - maybe when I am done I can post the reults ( convection and forced cooling) to help any future new constructors , as I have noticed that heat sinking is a common cause of questions.

And for the F5 turbo seems like we are going to need some serious heat sinks for that one.

- Home

- Amplifiers

- Pass Labs

- F5 power amplifier