I owe the world an apology

I am sorry for expressing my views upon the world. Politics is not needed on this forum and I was wrong.

It is not important as to why I feel and think the way I do. Because it is not the purpose of this forum.

If I hurt, insulted, or offended anyone. Please let me know, and we can talk it over off the forum.

I get on my soap box and speak out my Tea Party views. Without thinking that others have views as well.

Our problems in America, is just that; our problems. And my views are just that. My views.

I send my best to each and everyone of you, and your families.

Take Care

Ivey

I am sorry for expressing my views upon the world. Politics is not needed on this forum and I was wrong.

It is not important as to why I feel and think the way I do. Because it is not the purpose of this forum.

If I hurt, insulted, or offended anyone. Please let me know, and we can talk it over off the forum.

I get on my soap box and speak out my Tea Party views. Without thinking that others have views as well.

Our problems in America, is just that; our problems. And my views are just that. My views.

I send my best to each and everyone of you, and your families.

Take Care

Ivey

Those capacitances varied a lot, some had 3.4nF, the one I tested had 2nF and some had as small as 300pF. This would indeed indicate that they are fake. I measured the one with 300pF capacitance, and it survived 2A @ 65V. However, they had quite different Hfe, I did this experiment by simply putting a 2.2k resistor between Vcc and base. One problem I found with this one was that I was unable to get the current above 6A, even when using 100 ohm resistor and 30V voltage.

Hfe really should be measured with a constant current source feeding the base. don't forget there's a usually rather large beta droop when the transistor gets above a couple of amps. with some transistors, the beta droop is at a 50:1 ratio... in other words, you might read a beta of 100 at 100mA, but it might only be around 2 by the time you get above 3 or 4A. a lot of "switching" transistors are like this. audio output devices usually have about a 10:1 beta droop, and the really good ones with "stabilized beta" between 2:1 and 5:1. the constant current source should be driven from a separate power supply if possible. i've seen that within the same part number of legitimate transistors (for instance MJ15024), all samples tested, even from different date codes usually stay within about 10% of each other, and that a fake will have lower junction capacitance than the original. if a legitimate second source licenses the process from the original maker of the device, their part should be identical to the original. if the device is made to be "like" the original by a foundry that did not license the process, the part will be substandard, they don't own the original die masks, and don't have the correct layer thicknesses, or maybe not even the correct materials or equipment... the result is a substandard device that is unreliable and rarely meets the tolerances of the original part. this is what i call a "knock-off" or "wannabe". what sets these apart from the counterfeit is that the maker puts their own logo on it rather than try to make it look like the original part. the counterfeiter doesn't even try to make a part anywhere close to what they're faking, they just toss whatever die in there that will pass initial testing (i.e. powering the amp up without a load, or a purely resistive load), and try to make it look as much like the original device as they can (as cheaply as possible of course). of course the counterfeiters make their share of mistakes, but they have been improving their packaging methods, which makes a fake harder to spot by eye. knowing the varios manufacturer's marking methods (date code formats and their meanings, beta codes, mold marks, tool marks, etc) improves your ability to spot the fakes. just think, there are companies out there that make their bread and butter testing parts to identify fakes. it's amazing some of the stuff they find (i.e. a signetics die on a fake motorola chip, etc...). but they have X-ray machines, curve tracers, chip analyzers etc...

Our problems is just that, our problems.

Rather amusing, actually.

Some think of US problems not as just your problems only, which is not global hugging, merely caring about the well-being of hundreds of close but remote family members.

Fwiw, i buy a lot of parts in the US, because they're a whole lot cheaper and stand a better chance of being genuine.

Last edited:

Hfe really should be measured with a constant current source feeding the base. don't forget there's a usually rather large beta droop when the transistor gets above a couple of amps. with some transistors, the beta droop is at a 50:1 ratio... in other words, you might read a beta of 100 at 100mA, but it might only be around 2 by the time you get above 3 or 4A. a lot of "switching" transistors are like this. audio output devices usually have about a 10:1 beta droop, and the really good ones with "stabilized beta" between 2:1 and 5:1. the constant current source should be driven from a separate power supply if possible. i've seen that within the same part number of legitimate transistors (for instance MJ15024), all samples tested, even from different date codes usually stay within about 10% of each other, and that a fake will have lower junction capacitance than the original. if a legitimate second source licenses the process from the original maker of the device, their part should be identical to the original. if the device is made to be "like" the original by a foundry that did not license the process, the part will be substandard, they don't own the original die masks, and don't have the correct layer thicknesses, or maybe not even the correct materials or equipment... the result is a substandard device that is unreliable and rarely meets the tolerances of the original part. this is what i call a "knock-off" or "wannabe". what sets these apart from the counterfeit is that the maker puts their own logo on it rather than try to make it look like the original part. the counterfeiter doesn't even try to make a part anywhere close to what they're faking, they just toss whatever die in there that will pass initial testing (i.e. powering the amp up without a load, or a purely resistive load), and try to make it look as much like the original device as they can (as cheaply as possible of course). of course the counterfeiters make their share of mistakes, but they have been improving their packaging methods, which makes a fake harder to spot by eye. knowing the varios manufacturer's marking methods (date code formats and their meanings, beta codes, mold marks, tool marks, etc) improves your ability to spot the fakes. just think, there are companies out there that make their bread and butter testing parts to identify fakes. it's amazing some of the stuff they find (i.e. a signetics die on a fake motorola chip, etc...). but they have X-ray machines, curve tracers, chip analyzers etc...

Yep, the beta droop was quite noticeable, but even more noticeable was the difference between the two transistors I tested.

I complained to goodbuy711 (the eBay seller), and he offered to give me full refund without me having to send the parts back to him, which I accepted.

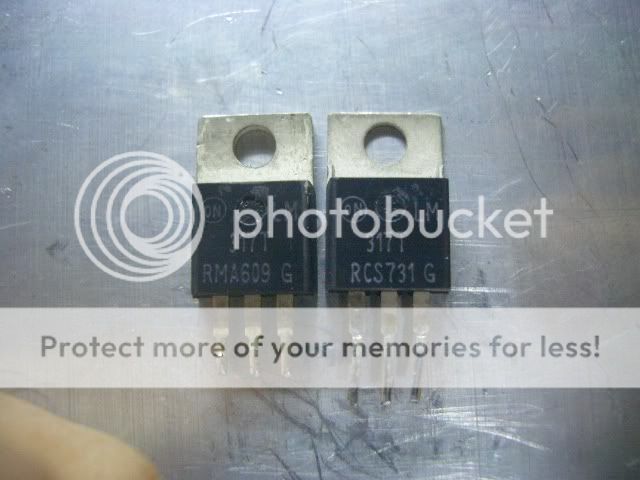

not fake

Interesting question. At first the thin one would seem a fake, but it is not. Manufacturers are introducing the thin TO 220 shape (0.5 mm baseplate), presumably to save on material and weight.

This may seem strange at first, but if you're making billions of these things this will add up to a large amount of saved material and cost over time.

Manufacturers of clamp-on heatsinks have introduced products suitable for this thinner shape.

Judging by the date codes on the ICs in the picture, ON switched to thin TO-220 for the LM317 somewhere between 2006 and 2007.

Some of the products the company I work for assembles uses the LM317 and LM337 in the PSU. The customer allows us the use of Fairchild, National, OnSemi or ST, whichever is available at lowest cost. So far Fairchild and OnSemi have switched to the thin TO220, National and ST are still normal TO220, although I expect they'll switch too...

not a transistor but also a semiconductor.....

I have already installed it on the PCB and then I noticed it looked funny so I took it out to take pictures so it hasn't seen power.

if you ask me, the one on the right screams "FAKE!!!". the tab is only 0.5mm thick!!!

what do you guys think?

Interesting question. At first the thin one would seem a fake, but it is not. Manufacturers are introducing the thin TO 220 shape (0.5 mm baseplate), presumably to save on material and weight.

This may seem strange at first, but if you're making billions of these things this will add up to a large amount of saved material and cost over time.

Manufacturers of clamp-on heatsinks have introduced products suitable for this thinner shape.

Judging by the date codes on the ICs in the picture, ON switched to thin TO-220 for the LM317 somewhere between 2006 and 2007.

Some of the products the company I work for assembles uses the LM317 and LM337 in the PSU. The customer allows us the use of Fairchild, National, OnSemi or ST, whichever is available at lowest cost. So far Fairchild and OnSemi have switched to the thin TO220, National and ST are still normal TO220, although I expect they'll switch too...

Oh, you did not get the memo from On Semi

The thin tab are being used because "we" the users are putting too much heat to the LM317's units.

We want the chip to do so much, that we over heat it and it fails. So the thinner tab, allows for better and quicker heat transfer when a heat sink is used or required. Plus, no doubt the companies are saving money.

The LM317 is now the go to chip regulator, for voltage regulation.

Take Care

Ivey

The thin tab are being used because "we" the users are putting too much heat to the LM317's units.

We want the chip to do so much, that we over heat it and it fails. So the thinner tab, allows for better and quicker heat transfer when a heat sink is used or required. Plus, no doubt the companies are saving money.

The LM317 is now the go to chip regulator, for voltage regulation.

Take Care

Ivey

Yes it is made of copper. But copper heat properties are different from other metals.

In the days of bow and arrows, shears, and armies march into battle. They learn that copper is a very, very good conductor of heat. Used in pots and pans. That is the reason the brass pots were so desired, because one could not control the cooking temperature for copper.

The faster that you can remove the heat from the chip. The longer it will last.

Take Care

Ivey

In the days of bow and arrows, shears, and armies march into battle. They learn that copper is a very, very good conductor of heat. Used in pots and pans. That is the reason the brass pots were so desired, because one could not control the cooking temperature for copper.

The faster that you can remove the heat from the chip. The longer it will last.

Take Care

Ivey

Richee:

1> copper is the best conductor of heat that we know of, that is inexpensive to use.

2> the thicker the copper tab, longer time required to transfer heat to a heat sink. So you make it thinner.

3> because the faster that you remove the heat from the chip. the less thermal damage that you place on the chip.

4> since we are all using the LM317 for all types of circuits, we sometimes we overload its ratings. So..., with a thinner tab, conduction of heat and the transfer of that heat will be faster.

5> problem is, that most of us do not think about heat sinking the thing, until we have physically touched it to determine if it needs it or not. Which is not a good practice to practice.

6> We want the heat sink or the heat area to be bigger; not the tad. SMD proved to us that a thinner tab transfers heat much quicker then a thicker tab. In that the thermal condition inside the package reaches operational temperatures less rapidly, reducing possible damage to the chip. Because with a thicker tab, the longer the heat will remain in and against the chip..

I hope I explain it clearly

Take Care

Ivey

1> copper is the best conductor of heat that we know of, that is inexpensive to use.

2> the thicker the copper tab, longer time required to transfer heat to a heat sink. So you make it thinner.

3> because the faster that you remove the heat from the chip. the less thermal damage that you place on the chip.

4> since we are all using the LM317 for all types of circuits, we sometimes we overload its ratings. So..., with a thinner tab, conduction of heat and the transfer of that heat will be faster.

5> problem is, that most of us do not think about heat sinking the thing, until we have physically touched it to determine if it needs it or not. Which is not a good practice to practice.

6> We want the heat sink or the heat area to be bigger; not the tad. SMD proved to us that a thinner tab transfers heat much quicker then a thicker tab. In that the thermal condition inside the package reaches operational temperatures less rapidly, reducing possible damage to the chip. Because with a thicker tab, the longer the heat will remain in and against the chip..

I hope I explain it clearly

Take Care

Ivey

Last edited:

Hi,1> copper is the best conductor of heat that we know of, that is inexpensive to use.

2> the thicker the copper tab, longer time required to transfer heat to a heat sink. So you make it thinner.

3> because the faster that you remove the heat from the chip. the less thermal damage that you place on the chip.

I hope I explain it clearly

not at all.

"Copper is the best we know of." Is it?

"longer time" or should you say higher rate of heat flow?

"faster that you remove the heat from the chip". precisely agrees with my last question. Time has little to do with heatflow in this context other than how much heat has passed across a boundary or interface in a specified period of time.

It is heat flow you should be considering, not time.

Gentlemen:

It is true, take a look at your CPU's. The chip tab is about 5mm to 6mm square. Your heat sink is huge. And tab is glass thin.

A huge heat sink tab on top of the CPU would keep the heat inside much too long. And damage the chips.

Because the more chips you pack into it, will require greater current. Equal heat.

The 8008, 8080,8086 and 88 did not require a heat sink, thus no tab, due to its size, overall area and lower chip count.

This in not a war story. This is fact

A thicker copper pot will take longer to heat up, compared to a thinner one. Pots are made thicker for durability, not heat conduction. A thicker pot, once heated, will hold heat in longer. But will not heat up and cook quicker.

Take Care

Ivey

It is true, take a look at your CPU's. The chip tab is about 5mm to 6mm square. Your heat sink is huge. And tab is glass thin.

A huge heat sink tab on top of the CPU would keep the heat inside much too long. And damage the chips.

Because the more chips you pack into it, will require greater current. Equal heat.

The 8008, 8080,8086 and 88 did not require a heat sink, thus no tab, due to its size, overall area and lower chip count.

This in not a war story. This is fact

A thicker copper pot will take longer to heat up, compared to a thinner one. Pots are made thicker for durability, not heat conduction. A thicker pot, once heated, will hold heat in longer. But will not heat up and cook quicker.

Take Care

Ivey

Andrew:

I am trying to keep it simple. Heat flow, is measured in temperature,time, heat source, material, material thickness and space gaps if any, etc. Using the time portion is easier.

But the quicker that you can have the heat flow moving away the your desire object the better.

For the newbies, look at heat flow, like water on the top of the ground sinking into the soil.

The quicker you can get the water to drain, the less bloody mess you will have on the surface.

Is that simple enough

Take Care

Ivey

I am trying to keep it simple. Heat flow, is measured in temperature,time, heat source, material, material thickness and space gaps if any, etc. Using the time portion is easier.

But the quicker that you can have the heat flow moving away the your desire object the better.

For the newbies, look at heat flow, like water on the top of the ground sinking into the soil.

The quicker you can get the water to drain, the less bloody mess you will have on the surface.

Is that simple enough

Take Care

Ivey

Last edited:

Andrew are you struggling as much as me to make any sense out of that?!!

Don't even try. I go back and forth about whether or not he's a troll. Remember the "discussion" about transistor numbering systems?

For confused newbies, please remember that the premium pans used by chefs are thick copper.

- Home

- Design & Build

- Parts

- My Transistors, original or copy?