Hi all!

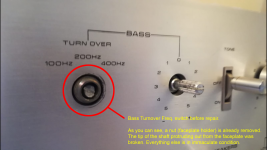

As the subject line says, I am looking for 3-position rotary switch (for "Bass Turnover Frequency" Positions) for Pioneer SA-8500 II model. Also, a knob that goes on that shaft is missing as well. Original part numbers from service manual are:

- Bass Turnover Frequency, rotary switch, 3-positions: ASD-057

- Knob: AAB-116

If any of fiune people has one SA-8500 II for spare parts I would gladly pay for that switch and for that knob.

Feel free to contact me and also, if you know someone who might have spare parts, possibly point me to other direction.

Any help is highly appreciated!

Thanks a lot!!!

Stay safe & take care,

Krešo

As the subject line says, I am looking for 3-position rotary switch (for "Bass Turnover Frequency" Positions) for Pioneer SA-8500 II model. Also, a knob that goes on that shaft is missing as well. Original part numbers from service manual are:

- Bass Turnover Frequency, rotary switch, 3-positions: ASD-057

- Knob: AAB-116

If any of fiune people has one SA-8500 II for spare parts I would gladly pay for that switch and for that knob.

Feel free to contact me and also, if you know someone who might have spare parts, possibly point me to other direction.

Any help is highly appreciated!

Thanks a lot!!!

Stay safe & take care,

Krešo

Hey MAAC0,

thanks but that one is not interexchangeable. I saw it, asked, checked around. Knobs are much easier to find. I am waiting for the Amp to arrives and then I will have hands-on battle with that problem.

I don't want to make this Amp a fraknestien one. It will be all original. Of course, when it comes to knob anyway. Worst case scenario will be saving the switch by taking some other knurled split shaft and (somehow) JB-Welg glueing or literally fining some elderly gentleman who has good knowledge on how to specially weld and reattach shaft part.

As one other gentleman whom I asked for switch said - it's a labour of love! ;-)

Easiest and best way is finding one original spare part.

Thanks for sending a word!

STay safe!

Krešo

thanks but that one is not interexchangeable. I saw it, asked, checked around. Knobs are much easier to find. I am waiting for the Amp to arrives and then I will have hands-on battle with that problem.

I don't want to make this Amp a fraknestien one. It will be all original. Of course, when it comes to knob anyway. Worst case scenario will be saving the switch by taking some other knurled split shaft and (somehow) JB-Welg glueing or literally fining some elderly gentleman who has good knowledge on how to specially weld and reattach shaft part.

As one other gentleman whom I asked for switch said - it's a labour of love! ;-)

Easiest and best way is finding one original spare part.

Thanks for sending a word!

STay safe!

Krešo

So bass switches two caps. Use a treble switch to switch 3 2 contacts relays.

Perhaps one of these would work 4 contacts 3 positions.

https://www.retroamplis.com/epages/...ps/62070367/Products/"SW-ROT/TW-4POL/3POS-SL"

Perhaps one of these would work 4 contacts 3 positions.

https://www.retroamplis.com/epages/...ps/62070367/Products/"SW-ROT/TW-4POL/3POS-SL"

So bass switches two caps. Use a treble switch to switch 3 2 contacts relays.

Perhaps one of these would work 4 contacts 3 positions.

https://www.retroamplis.com/epages/...ps/62070367/Products/"SW-ROT/TW-4POL/3POS-SL"

I checked that source you sent me. I need to continue my search. Amp has finally arrived and now I am in real position of either eyeballing or tkaing it apart to see whether the shaft alone can be replaced or not. If my eyes are not deceiving me I would say that switch can be disassembled. So I can either find replacement switch or find any donor (ALPS-like rotary switch) that have same or similar construction. Same shaft in lenth or longer is OK. If all of this don't give any result I can always give steel rod to a CNC master to make me a shaft accoridng to specs and drawing.

I am so going to restore this beauty! ;-)

I believe it goes without saying that I still am interested to buy either switch or the whole Tone Control Board!

Anyone can send me a message if have spare parts in question!

Stay safe!!!

Krešo

Try Pacific Stereo.

Welcome To Pacific Stereo - Vintage Audio Repair, Parts and Much More!

Welcome To Pacific Stereo - Vintage Audio Repair, Parts and Much More!

Hey MAAC0,

nope, Pacific Stereo couldn't help. Thou i have contacted him about a motor which I might be buying. ;-)

But hey, thanks for the info just the same!

Krešo

PS: See below another tip. I am waiting for their answer with high hope!

I sent a message and if all goes well... ;-)

Thanks for this tip!!! A lot!

Stay safe,

Krešo

Thanks all for all your tips and help but I guess as some elderly pros told me when I contacted quite a few all over the world (US, Japan, Europe...) that these parts most likely will come from donor machine.

So, I went the other way looking for exactly the same type of switches that can be disassembled and taken apart to use just the shaft and tailor it to my needs.

I found a few and finally ordered one. If by some dumb luck someone finds on I am still willing to buy but I don't think that will happen.

I am so saving nice SA-8500II and restoring it to former glory.

So, I went the other way looking for exactly the same type of switches that can be disassembled and taken apart to use just the shaft and tailor it to my needs.

I found a few and finally ordered one. If by some dumb luck someone finds on I am still willing to buy but I don't think that will happen.

I am so saving nice SA-8500II and restoring it to former glory.

Hi all!

I would like to thank all for participating any giving me feedback. I solved the switch and I am simply pasting what I wrote on AK. ;-)

So, it's been a while but finally rotary switch has been dealt with. It's all working now and repair, as hard as it seemed in the beginning, was really easy. For all interested in similar situation (in case a piece of shaft that is protruding out from the faceplate anyway) I can tell you that there is no need of welding, dremmeling, filing off etc. as long as rotary switch is healthy, not bent or broken all the way to the end.

Now, the hardest part was to find exact same design of rotary switch that Pioneer outsourced (or they had their own mills, I don't know that detail) and installed in their units. Exact same part number I haven't been able to find but I did find one that had longer shaft. So, with a little bit of brainstorming and checking out donor switch (and contacting a few folks I know or found online - thanks Buddy) with my neighbour solution presented itself. No drilling, no disassembly (other than switches), no desoldering, nothing... Story is that all those switches (so far I know all ASD series) are the same but their length varies, depending on unit construction and utility of that switch. Shaft can be pulled out and switch left in place, all wafers and all soldered. Be gentle, be very careful and slowly pull out broken shaft. Now, my donor was longer. No big deal. All those switches comes with enough small parts (like those cilinders that goes on two long screws holding switch construction in place) and since my "new" shaft was longer I simply added those "elongaters (cylinders) and put all back together. Now, while I had Tone Control Board out I noticed a few Caps were higher and getting in the way of new, longer shaft. I replaced on that Board two Caps on the left and 2 on the right side (I had at home 4x100uF 25V electrolytics). Newly made Caps are twice smaller, both in heigth and diameter, so after they were replaced nothing else was in the way of newly placed shaft. Yes, it is 1-2 cm longer but it doesn't matter. It has no other function than rotating around it's axis. Right? So, initially I was pretty worried because I haven't ever disassemble old rotary switches. This ones, their construcion, is done in such a way that it is easy to work with.

In case any of you find yourself in similar situation you can go this way. Of course, issue must be as mine, partially broken shaft.

I just wanted to thank you all who participated and wrote back.

Stay safe!

I would like to thank all for participating any giving me feedback. I solved the switch and I am simply pasting what I wrote on AK. ;-)

So, it's been a while but finally rotary switch has been dealt with. It's all working now and repair, as hard as it seemed in the beginning, was really easy. For all interested in similar situation (in case a piece of shaft that is protruding out from the faceplate anyway) I can tell you that there is no need of welding, dremmeling, filing off etc. as long as rotary switch is healthy, not bent or broken all the way to the end.

Now, the hardest part was to find exact same design of rotary switch that Pioneer outsourced (or they had their own mills, I don't know that detail) and installed in their units. Exact same part number I haven't been able to find but I did find one that had longer shaft. So, with a little bit of brainstorming and checking out donor switch (and contacting a few folks I know or found online - thanks Buddy) with my neighbour solution presented itself. No drilling, no disassembly (other than switches), no desoldering, nothing... Story is that all those switches (so far I know all ASD series) are the same but their length varies, depending on unit construction and utility of that switch. Shaft can be pulled out and switch left in place, all wafers and all soldered. Be gentle, be very careful and slowly pull out broken shaft. Now, my donor was longer. No big deal. All those switches comes with enough small parts (like those cilinders that goes on two long screws holding switch construction in place) and since my "new" shaft was longer I simply added those "elongaters (cylinders) and put all back together. Now, while I had Tone Control Board out I noticed a few Caps were higher and getting in the way of new, longer shaft. I replaced on that Board two Caps on the left and 2 on the right side (I had at home 4x100uF 25V electrolytics). Newly made Caps are twice smaller, both in heigth and diameter, so after they were replaced nothing else was in the way of newly placed shaft. Yes, it is 1-2 cm longer but it doesn't matter. It has no other function than rotating around it's axis. Right? So, initially I was pretty worried because I haven't ever disassemble old rotary switches. This ones, their construcion, is done in such a way that it is easy to work with.

In case any of you find yourself in similar situation you can go this way. Of course, issue must be as mine, partially broken shaft.

I just wanted to thank you all who participated and wrote back.

Stay safe!

Pioneer SA-8500II - Rotary Switch Repaired, Pt. 1

Hi girls & boys!

Here is direct copy (I really don't see the point writing this all over again) I posted over on Audikarma. If anyone should find him/herself in same position this is one way to approach this matter.

- - - START COPY - - -

Hi everyone!

So, it's been a while but finally rotary switch has been dealt with. It's all working now and repair, as hard as it seemed in the beginning, was really easy. For all interested in similar situation (in case a piece of shaft that is protruding out from the faceplate anyway) I can tell you that there is no need of welding, dremmeling, filing off etc. as long as rotary switch is healthy, not bent or broken all the way to the end.

Now, the hardest part was to find exact same design of rotary switch that Pioneer outsourced (or they had their own mills, I don't know that detail) and installed in their units. Exact same part number I haven't been able to find but I did find one that had longer shaft. So, with a little bit of brainstorming and checking out donor switch (and contacting a few folks I know or found online - thanks Buddy) with my neighbour solution presented itself. No drilling, no disassembly (other than switches), no desoldering, nothing... Story is that all those switches (so far I know all ASD series) are the same but their length varies, depending on unit construction and utility of that switch. Shaft can be pulled out and switch left in place, all wafers and all soldered. Be gentle, be very careful and slowly pull out broken shaft. Now, my donor was longer. No big deal. All those switches comes with enough small parts (like those cilinders that goes on two long screws holding switch construction in place) and since my "new" shaft was longer I simply added those "elongaters (cylinders) and put all back together. Now, while I had Tone Control Board out I noticed a few Caps were higher and getting in the way of new, longer shaft. I replaced on that Board two Caps on the left and 2 on the right side (I had at home 4x100uF 25V electrolytics). Newly made Caps are twice smaller, both in heigth and diameter, so after they were replaced nothing else was in the way of newly placed shaft. Yes, it is 1-2 cm longer but it doesn't matter. It has no other function than rotating around it's axis. Right? So, initially I was pretty worried because I haven't ever disassemble old rotary switches. This ones, their construcion, is done in such a way that it is easy to work with.

In case any of you find yourself in similar situation you can go this way. Of course, issue must be as mine, partially broken shaft.

I just wanted to thank you all who participated and wrote back.

Stay safe!

- - - END - - -

EDIT: For some reason I can not post pics. I will definitely try again. So far the only thing is this post. Sorry. ;-)

Hi girls & boys!

Here is direct copy (I really don't see the point writing this all over again) I posted over on Audikarma. If anyone should find him/herself in same position this is one way to approach this matter.

- - - START COPY - - -

Hi everyone!

So, it's been a while but finally rotary switch has been dealt with. It's all working now and repair, as hard as it seemed in the beginning, was really easy. For all interested in similar situation (in case a piece of shaft that is protruding out from the faceplate anyway) I can tell you that there is no need of welding, dremmeling, filing off etc. as long as rotary switch is healthy, not bent or broken all the way to the end.

Now, the hardest part was to find exact same design of rotary switch that Pioneer outsourced (or they had their own mills, I don't know that detail) and installed in their units. Exact same part number I haven't been able to find but I did find one that had longer shaft. So, with a little bit of brainstorming and checking out donor switch (and contacting a few folks I know or found online - thanks Buddy) with my neighbour solution presented itself. No drilling, no disassembly (other than switches), no desoldering, nothing... Story is that all those switches (so far I know all ASD series) are the same but their length varies, depending on unit construction and utility of that switch. Shaft can be pulled out and switch left in place, all wafers and all soldered. Be gentle, be very careful and slowly pull out broken shaft. Now, my donor was longer. No big deal. All those switches comes with enough small parts (like those cilinders that goes on two long screws holding switch construction in place) and since my "new" shaft was longer I simply added those "elongaters (cylinders) and put all back together. Now, while I had Tone Control Board out I noticed a few Caps were higher and getting in the way of new, longer shaft. I replaced on that Board two Caps on the left and 2 on the right side (I had at home 4x100uF 25V electrolytics). Newly made Caps are twice smaller, both in heigth and diameter, so after they were replaced nothing else was in the way of newly placed shaft. Yes, it is 1-2 cm longer but it doesn't matter. It has no other function than rotating around it's axis. Right? So, initially I was pretty worried because I haven't ever disassemble old rotary switches. This ones, their construcion, is done in such a way that it is easy to work with.

In case any of you find yourself in similar situation you can go this way. Of course, issue must be as mine, partially broken shaft.

I just wanted to thank you all who participated and wrote back.

Stay safe!

- - - END - - -

EDIT: For some reason I can not post pics. I will definitely try again. So far the only thing is this post. Sorry. ;-)

Attachments

Last edited:

- Home

- Design & Build

- Parts

- Pioneer SA-8500 II - Looking for Bass Turnover Rotary Switch (orig. part no. ASD-057)