A commercial 3D printing service, or a rapid prototyping service.

The drawing creation is the expensive part,

here at least there are people who charge a lot of money to measure or visualize the part using equipment like co ordinate measuring machines and binocular cameras.

That data is converted to 3D files which can be read in programs like AutoCad, or Solid Edge.

Canon now makes 3D printers, they were $300 here last I checked.

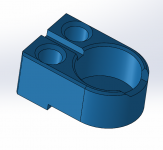

Looks like Nylon 6/6 or Delrin.

Is it possible to use another functionally similar device, rather than make all this effort?

The drawing creation is the expensive part,

here at least there are people who charge a lot of money to measure or visualize the part using equipment like co ordinate measuring machines and binocular cameras.

That data is converted to 3D files which can be read in programs like AutoCad, or Solid Edge.

Canon now makes 3D printers, they were $300 here last I checked.

Looks like Nylon 6/6 or Delrin.

Is it possible to use another functionally similar device, rather than make all this effort?

Last edited:

A seller currently has 3 NOS on Ebay.

STUDER 1.810.125.00 SENSOR COIL A67 A807 A810 A812 B67 Teil. NEW NOS RARE | eBay

STUDER 1.810.125.00 SENSOR COIL A67 A807 A810 A812 B67 Teil. NEW NOS RARE | eBay

Same here.Is it possible to use another functionally similar device, rather than make all this effort?

What´s it used for?

An end or broken tape detector?

Part of a reel or capstan speed controller?

Maybe you can mod Tape Recorder to use some kind of optical detector to detect/trigger whatever´s needed.

OR you may fabricate an equivalent bobbin holder out of a small piece of Acrylic or ABS sheet: top - bottom - separator

You cut-drill-glue them together, glue bobbin to top nd bottom or drill themso you can "embed coils as in original part (not sure about available space) and drill small "guide holes".

I guess this part slides up-down on two polished/chromed metal guides for fine adjustment.

Last edited:

Thanks for the tip! I downloaded the e machine CAD program and started the tutorial---seems sorta arcane so far, but I'll keep trying.Try on the e-machines site...it was a site for buyers and sellers of machined and molded parts.

Or a similar site.

It is to be used as a tension sensor on my Otari reel-to-reel tape recorder. It senses the position of the existing tension arm in order to control the holdback/takeup tension. I am woefully under the delusion that I can make and retro-fit a reel servo control for this machine so it can handle tape like the big boys (Studer and Ampex) do.What´s it used for?....I guess this part slides up-down on two polished/chromed metal guides for fine adjustment.

I sent you a PM. That's the best pic I got; the only other guideline I have is the pot core/bobbin datasheet:I can probably do you up a set out of milled nylon. Can you provide more pictures/dimensions?

https://product.tdk.com/system/file...e/ferrite-acc/data_sheet/80/db/fer/p_14_8.pdf

The spec helps a little. The coil is actually 14.3mm x 8, so making that mounting hole would probs need to be 14.4mm, depending on the fit.

The real issue is the spacing of those two pin sleeves in relation to themselves. You would have to either take the measurements yourself (with calipers at a bare minimum) or send the assembly, with coil, to me to measure.

If you want to go the printer route, just come up with the best measurements you can and I'll implement them in an STL file, and you can print one out. If it doesn't fit, I can tweak the dimensions and re-STL-

The real issue is the spacing of those two pin sleeves in relation to themselves. You would have to either take the measurements yourself (with calipers at a bare minimum) or send the assembly, with coil, to me to measure.

If you want to go the printer route, just come up with the best measurements you can and I'll implement them in an STL file, and you can print one out. If it doesn't fit, I can tweak the dimensions and re-STL-

- Home

- Design & Build

- Parts

- Plastic 3-D printed part