We have more options than ever for SMT caps these days. Manufacturers are beginning to designate some types "for audio," and frequently tout the measured performance of these "good" SMT caps against the clearly inferior X7R types for dramatic effect. Yet we seldom see comparisons of the various "good" types against each other.

I'll start with dielectric absorption and hope that other members will chime in to share other important considerations, including subjective preferences

I found that by combining data from the following sources, I could draw a general comparison of dielectric absorption between the "good" surface mount cap types, including:

- Class 1 ceramics (C0G)

- Acrylic film types (PMMA)

- Polyphenylene sulphide film (PPS).

--

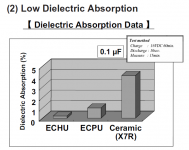

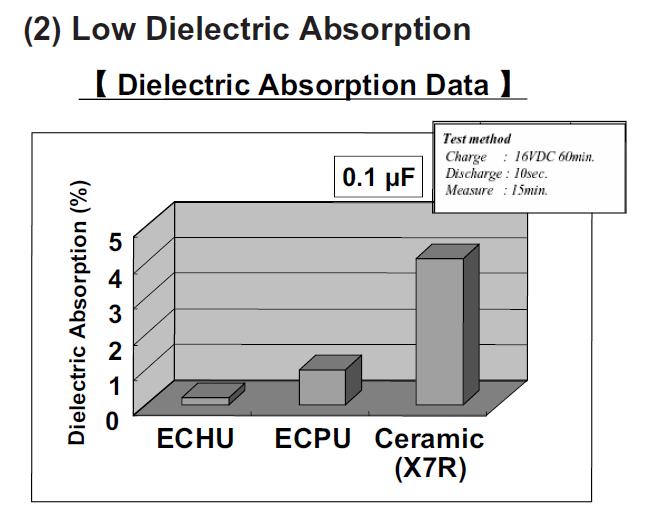

Here's PPS vs. PMMA vs. X7R, from an older Panasonic ECPU datasheet:

Film Chip Capacitor ECHU(B) Datasheet

Eyeballing it: PPS 0.1%, PMMA 0.8%.

---

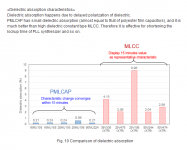

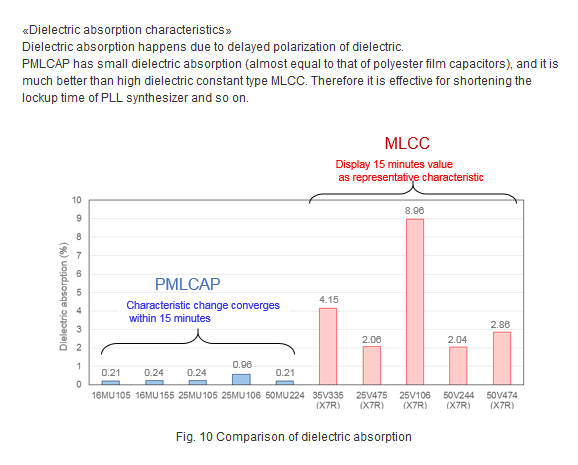

Rubycon's PMLCAPs (MU series) have near identical dielectric absorption compared to the Panasonics. From the PMLCAP technical notes:

PMLCAP Technical Notes/Hybrid, Capacitor, Power Supply Units

They measured 0.21%-0.96%.

---

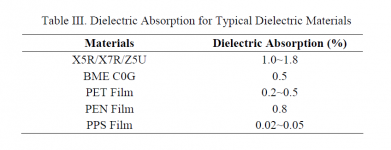

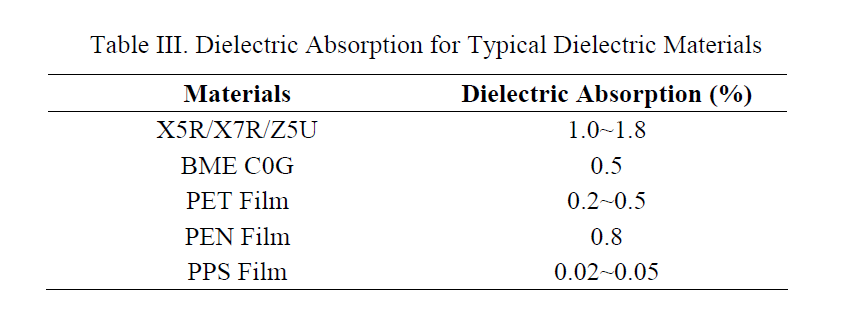

It's harder to find comparisons of the SMT film caps with C0G. I think manufacturers like to compare their films with X7R because the difference is more drastic. But Kemet offers this chart in a technical article:

Advances in Class-I C0G MLCC and SMD Film Capacitors

A Rosetta stone of sorts. PPS is in the ballpark of the Panasonic bar graph

---

Putting it all together:

C0G - 0.5%

PMMA - 0.2-1.0%

PPS - 0.02-0.1%

Wow. PPS is an order of magnitude better! Cyril Bateman would be pleased.

I'll start with dielectric absorption and hope that other members will chime in to share other important considerations, including subjective preferences

I found that by combining data from the following sources, I could draw a general comparison of dielectric absorption between the "good" surface mount cap types, including:

- Class 1 ceramics (C0G)

- Acrylic film types (PMMA)

- Polyphenylene sulphide film (PPS).

--

Here's PPS vs. PMMA vs. X7R, from an older Panasonic ECPU datasheet:

Film Chip Capacitor ECHU(B) Datasheet

Eyeballing it: PPS 0.1%, PMMA 0.8%.

---

Rubycon's PMLCAPs (MU series) have near identical dielectric absorption compared to the Panasonics. From the PMLCAP technical notes:

PMLCAP Technical Notes/Hybrid, Capacitor, Power Supply Units

They measured 0.21%-0.96%.

---

It's harder to find comparisons of the SMT film caps with C0G. I think manufacturers like to compare their films with X7R because the difference is more drastic. But Kemet offers this chart in a technical article:

Advances in Class-I C0G MLCC and SMD Film Capacitors

A Rosetta stone of sorts. PPS is in the ballpark of the Panasonic bar graph

---

Putting it all together:

C0G - 0.5%

PMMA - 0.2-1.0%

PPS - 0.02-0.1%

Wow. PPS is an order of magnitude better! Cyril Bateman would be pleased.

Attachments

Last edited:

But they are cheap and small. I have an extensive assortment of C0G/NP0 SMD capacitors from a few pF up to 1nF, all for different footprints, 50 pieces per value. They all fit into a small binder and I have every value I could ever need, neatly organised and ready to go. If I wanted the same for film caps, I would probably have to spend hundreds of dollars and it would take up half a room. I also have some SMD film caps, but they are usually damn expensive and they really don't like heat.

I also have some SMD film caps, but they are usually damn expensive and they really don't like heat.

I have used Pana ECHU to replace all the ceramics in a couple of dacs. Serious sonic improvement to my ears, worth every cent. Thank goodness these exist.

Yeah I have a bunch of these Panasonic SMD film caps as well. But as I said they are damn expensive and sensitive to heat on top of that. Most of my projects would probably double their BOM cost just by using them and I really wouldn't recommend hand soldering these things without properly preheating the board.

I understand that some SMD film caps are indeed temperature sensitive. So far, I have had success hand-soldering Rubycon PMLCAP and WIMA SMD-PPS with no apparent damage, and good sound.

Good to know. I already replaced X7R with PMLCAP on my DAC, and felt that lifted the sound quality a little. Now I plan to try replacing C0G with PPS, though I'm not sure if that difference will be as easy to hear.

I have used Pana ECHU to replace all the ceramics in a couple of dacs. Serious sonic improvement to my ears, worth every cent. Thank goodness these exist.

Good to know. I already replaced X7R with PMLCAP on my DAC, and felt that lifted the sound quality a little. Now I plan to try replacing C0G with PPS, though I'm not sure if that difference will be as easy to hear.

I have used Pana ECHU to replace all the ceramics in a couple of dacs. Serious sonic improvement to my ears, worth every cent. Thank goodness these exist.

Anecdote++

If you define better as closer to the behaviour of an ideal capacitor, then lower dielectric absorption is surely better.

It could be that some other parameter is worse for PPS than for NP0, but like stellarelephant wrote, he/she/it starts with dielectric absorption and hopes that other members will chime in to share other important considerations.

It could be that some other parameter is worse for PPS than for NP0, but like stellarelephant wrote, he/she/it starts with dielectric absorption and hopes that other members will chime in to share other important considerations.

Last edited:

This is an excellent idea for a thread, and good research, Stellar.

For distortion, voltage coefficient is the most important capacitor spec. Most of the time you are compensating the VAS of a power amplifier, so the voltage swing is rail-to-rail, and the C needs to stay constant. ESR doesn't matter, because you probably have a series resistor anyway, and if you don't you should. C0G works well here, and silver silver mica works even better.

For filtering, the NP0/C0G types can only get you to 0.1uF, and that's expensive. That where the PPS and other film types come in handy. I've used plenty of film and metal-film caps, and not had trouble. Polyproplyene is nice, but large.

When I hand solder SMD film caps, I buy plenty extra, because I know I'm going to botch some of them I try to solder those first, so I can test them, post-solder.

For distortion, voltage coefficient is the most important capacitor spec. Most of the time you are compensating the VAS of a power amplifier, so the voltage swing is rail-to-rail, and the C needs to stay constant. ESR doesn't matter, because you probably have a series resistor anyway, and if you don't you should. C0G works well here, and silver silver mica works even better.

For filtering, the NP0/C0G types can only get you to 0.1uF, and that's expensive. That where the PPS and other film types come in handy. I've used plenty of film and metal-film caps, and not had trouble. Polyproplyene is nice, but large.

When I hand solder SMD film caps, I buy plenty extra, because I know I'm going to botch some of them I try to solder those first, so I can test them, post-solder.

in some dacs and clock, acrylic & PPS smt caps give better sonic results than C0G in my experience, though I dunno if it is because of a nicer distorsion/coloration.

On the bad side of their use: they are bad when you need precise values and their capacitance drift fastly and easily with the heat of the soldering process.

If hearing is the goal, you have to try both in the same circuitry to know. I'm with AnalogSa here though.

On the bad side of their use: they are bad when you need precise values and their capacitance drift fastly and easily with the heat of the soldering process.

If hearing is the goal, you have to try both in the same circuitry to know. I'm with AnalogSa here though.

Thanks for the comments. When exact value is critical, a few PPS series are available in 2% tolerance, but it sounds like all bets are off as soon as you heat them! I can see how this could preclude their use in in some filters, or when attempting to match values between left and right channels, for instance. But I can still think of other places I'd like to try them...

You can get 100 nF C0G/NP0 in 1206. They're not cheap, but they work well.

You can get 1% COG in 100nF 1206 from Murata, I have a gram amp based around those in the RIAA filter, works just fine.

Murata's 1206-sized C0Gs now top out at 220nF but they're on a long lead time : https://www.mouser.com/ProductDetail/Murata-Electronics/GRM31C5C1H224JE02L?qs=sGAEpiMZZMvsSlwiRhF8qtsBU8Zhqm2R2h20Tjj%252BsyoT2MOwyf0Xlg%3D%3D

Thanks for the comments. When exact value is critical, a few PPS series are available in 2% tolerance, but it sounds like all bets are off as soon as you heat them! I can see how this could preclude their use in in some filters, or when attempting to match values between left and right channels, for instance. But I can still think of other places I'd like to try them...

I bought a lot of NOS styrenes from Philips for that purpose (filters and matching the channels)... not smt stuffs though. When not precise values are needed I like a lot the acrylic caps John from ECdesigns was talking in the digital line section (Cornell Dublier FCA) as decoupling to ground. I find they "sound" not the same as decoupling cap than the PPS you're talking about (the 2% from Panasonic I assume) that Pedja Rogic from Audial for instance uses in his dacs. I have not tested the PPS from Rubycon yet... certainly close or similar than the Panasonic while avaliable in much larger capacitance.

Last edited:

Diyiggy, I'm glad to get your recommendation for CDE FCA acrylics for decoupling, especially since they are relatively affordable. Can you describe their sound versus ECHU PPS, in your experience?

Also, I don't think Rubycon offers a PPS cap. I think you mean the acrylic PMLCAPs. They go all the way up to 22uF!

Also, I don't think Rubycon offers a PPS cap. I think you mean the acrylic PMLCAPs. They go all the way up to 22uF!

It's relative to the circuitry. Sometimes, it can gives you something a little smoother and more organic/meatier than a ceramic class I, or the Panasonic PPS at decoupling area (quite neutral this last without special signature). In some others circuitry I hear no difference, so you have to try. Halas as you saidn too much fragile, so after a soldering and desoldering they are almost dead or drift to much losing capacitance : very fast soldering needed, and desoldering is too long.

Very usefull for instance to decouple a Crystek clock for illustration (I use it 1uF on one of the two Crysteq of a Iancanada masterclock for a very enhanced sound in my system which is on the light/bright side a little too much. Of Course the capacitance precision is 10% at best iirc instead the 2% of the most precise PPS Panasonic serie.

usefull if you find your NP0 too much clear or bright. A good analogy when it works (halas not everywhere) is like a styren in a speaker filter for a C0G and a polypro paper foil for the FCCA (sort of, just for illustration, so when it works, difference is noticable enough... not always guaranted alas).

I beleive Pedja Rogic and John from ECEDESIGN know what they do and use them for a long time as they of course also use ceramic class I and II where it doesn't arm for the last or small inductance is needed (small casing).

Very usefull for instance to decouple a Crystek clock for illustration (I use it 1uF on one of the two Crysteq of a Iancanada masterclock for a very enhanced sound in my system which is on the light/bright side a little too much. Of Course the capacitance precision is 10% at best iirc instead the 2% of the most precise PPS Panasonic serie.

usefull if you find your NP0 too much clear or bright. A good analogy when it works (halas not everywhere) is like a styren in a speaker filter for a C0G and a polypro paper foil for the FCCA (sort of, just for illustration, so when it works, difference is noticable enough... not always guaranted alas).

I beleive Pedja Rogic and John from ECEDESIGN know what they do and use them for a long time as they of course also use ceramic class I and II where it doesn't arm for the last or small inductance is needed (small casing).

Last edited:

- Home

- Design & Build

- Parts

- Comparing "Good" SMT Capacitors - C0G vs. PMMA (Acrylic) vs. PPS